On-line monitoring and fault diagnosis method of multi-working condition process for ultra-high-speed carton packaging machine in cigarette factory

A fault diagnosis, ultra-high-speed technology, applied in the direction of program control, electrical test/monitoring, test/monitoring control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

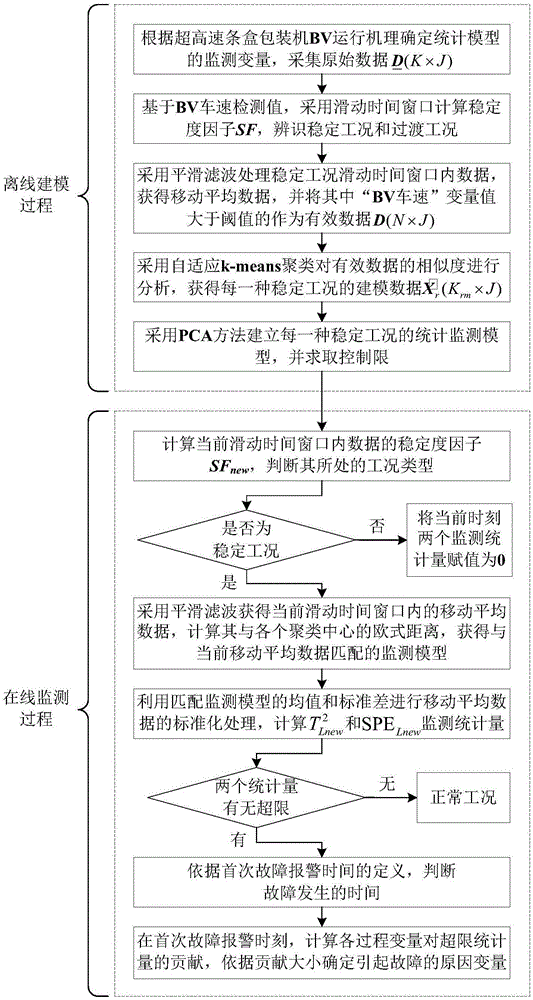

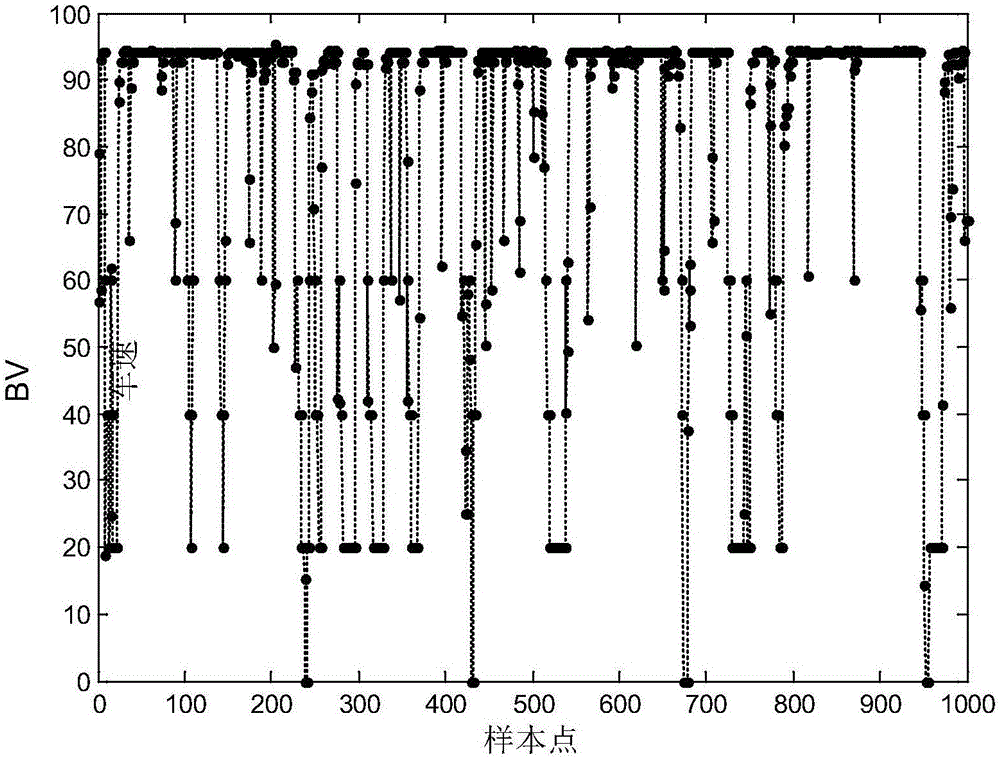

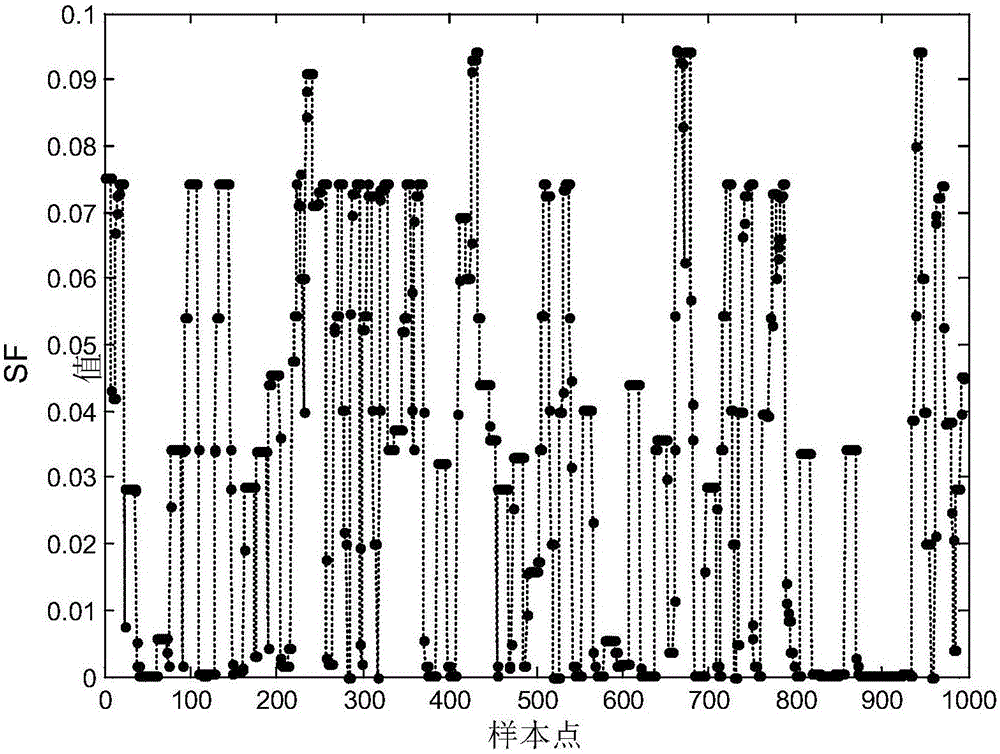

[0070] In order to better understand the technical solutions of the present invention, the implementation manners of the present invention will be further described below in conjunction with the accompanying drawings. During the cigarette packaging process, G.D’s ultra-high-speed packaging equipment consists of three parts: the small box packaging machine H1000, the small box film packaging machine W1000, and the carton packaging machine BV. This implementation is used for online monitoring and failure of the ultra-high-speed carton packaging machine BV diagnosis method. Carton Packing Machine BV is a high-speed automatic carton packing machine that can pack all kinds of cartons with different characteristics and hardness. The block diagram of the multi-working condition process online monitoring and fault diagnosis method of the ultra-high-speed carton packaging machine in the cigarette factory of the present invention is as follows: figure 1 As shown, the method is mainly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com