Method for measuring laser linewidth of ultra-narrow linewidth laser

A technology of ultra-narrow line width and laser line width, which is applied in the field of laser line width measurement of lasers, can solve the problems of submerged laser line width and difficult measurement of laser line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

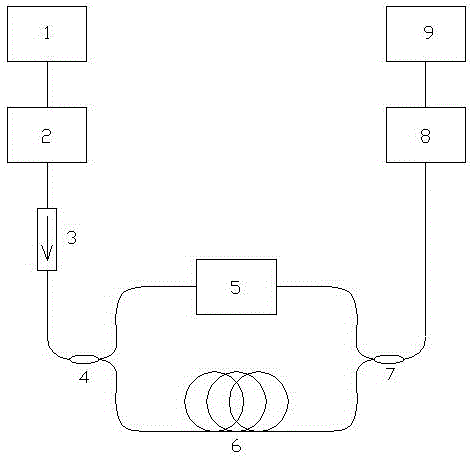

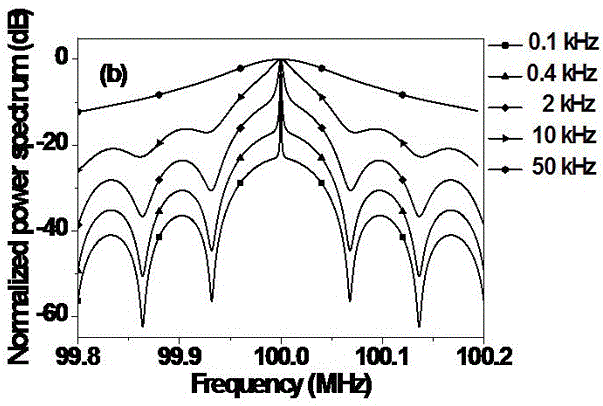

[0046] A method for measuring the laser linewidth of an ultra-narrow linewidth laser, the innovation of which is: using a self-heterodyne detection system to obtain the power spectrum of an ultra-narrow linewidth laser under heterodyne conditions; , select a peak and a trough that are adjacent to each other, calculate the difference ΔS of the contrast between the peak and the trough on the power spectrum, and then calculate the laser linewidth Δf according to the following formula:

[0047] ΔS=10log 10 S(F1,Δf)-10log 10 S(F2,Δf)

[0048] Wherein, F1 is the detection frequency of the spectrum analyzer at the peak position on the power spectrum, and F2 is the detection frequency of the spectrum analyzer at the valley position on the power spectrum;

[0049] In the previous formula, S(F1,Δf)=S1 # ·S2 # , S(F2,Δf)=S1 * ·S2 * ; where, S1 # is the Lorentzian line spectrum corresponding to F1, S2 # is the periodic sine modulation spectrum corresponding to F1, S1 * is the Lor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com