Machinery device fault combination prediction system and method

A fault combination and prediction system technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of complex structure of mechanical equipment and difficult establishment of mathematical models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

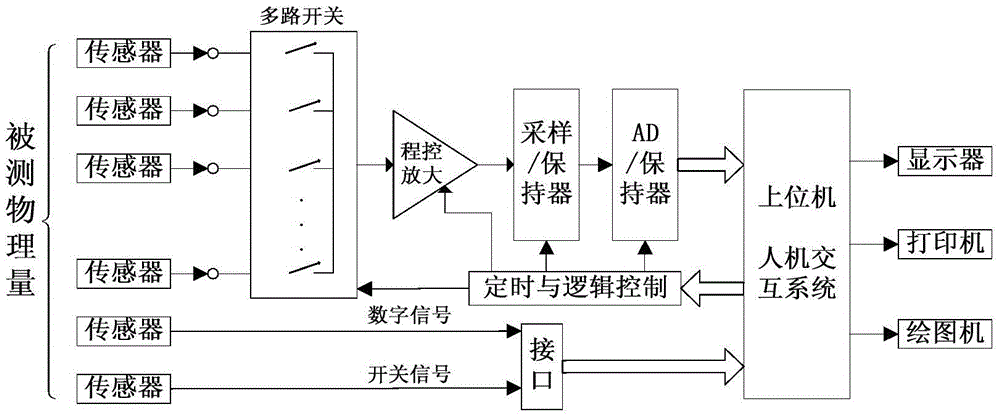

[0036] according to figure 1 The structure of the mechanical equipment failure combination prediction system shown in the figure is to install various types of sensors at appropriate test points of the monitored equipment. The signals output by these sensors are 4mA-20mA or 0V-5V analog signals, and the output of the sensors is connected to the sensor with a shielded cable. The signal is connected to the corresponding input end of the data acquisition system to realize the acquisition of the measured parameters. Perform A / D conversion on the collected signal, select the appropriate sampling frequency and accuracy, and select the network transmission form such as field bus, wireless or Ethernet according to the amount of data to be transmitted and the transmission distance, and transmit the data to the upper industrial computer.

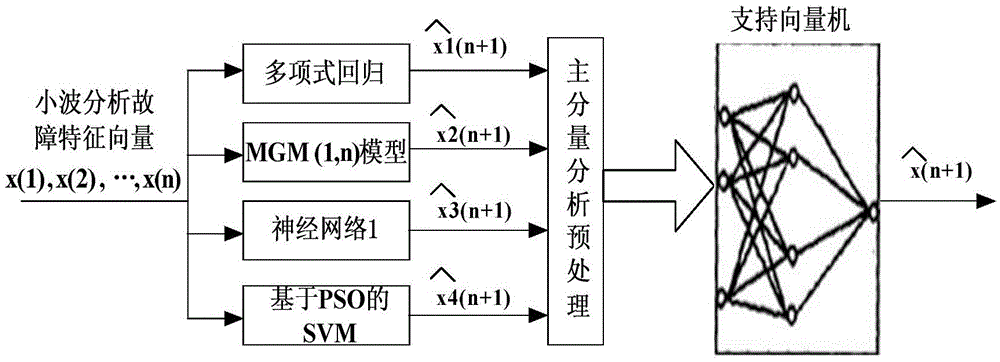

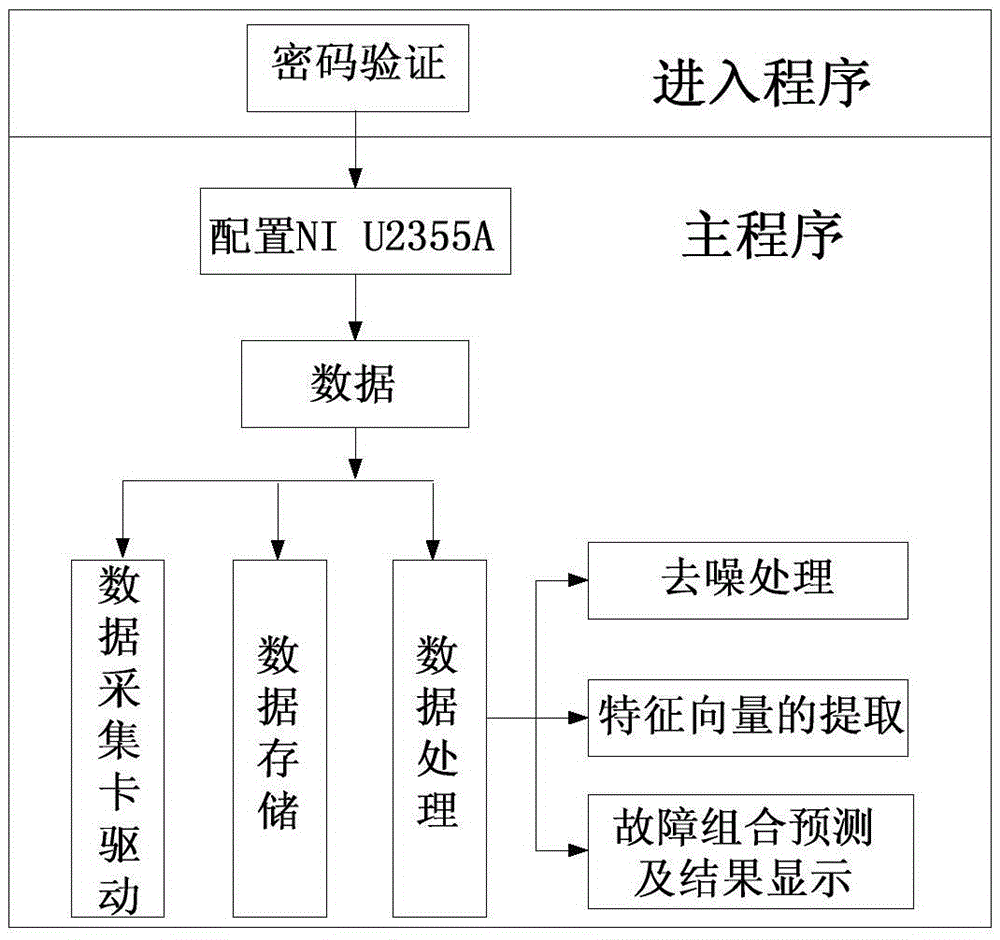

[0037] In the upper computer, the collected signal is according to figure 2 The process shown, using the image 3 The software in the human-comput...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com