Method of installing heating module on basic surface

A technology of base surface and installation structure, applied in heating methods, household heating, electric heating systems, etc., can solve the problems of limited laying area, inability to heat quickly, and high requirements on laying conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

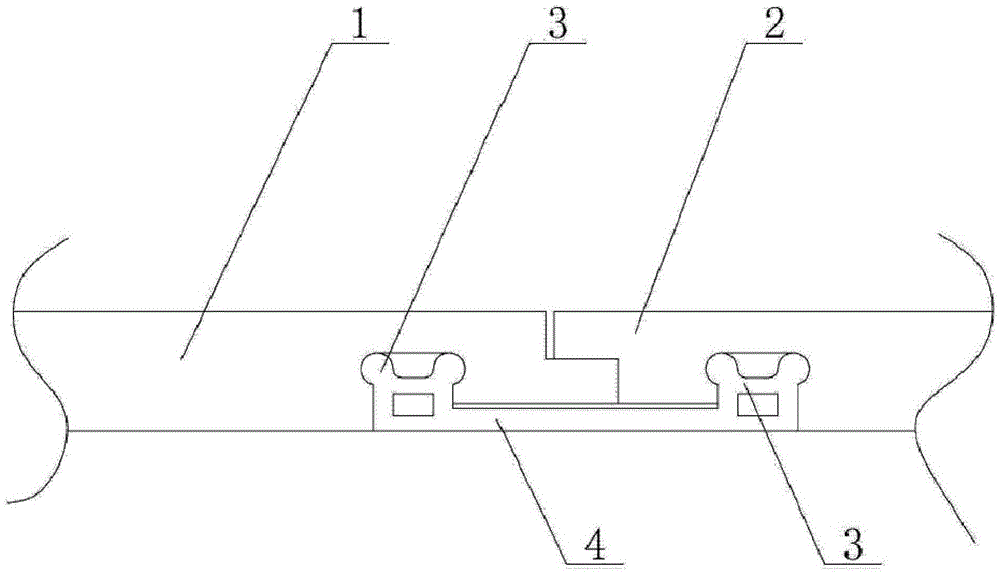

[0017] figure 1 As shown, a method of installing the heating module on the base surface. In practice, the base surface is selected as a wall, the carrier is a wooden board, and the heating material is placed on the surface of the carrier.

[0018] Please refer to figure 1 As shown, the installation structure includes a clip made of plastic material, adjacent first heating module 1 and second heating module 2, the first heating module 1 and the second heating module 2 are mortised, and the first heating module Module 1 and the lower end surfaces of the second heating module 2 are provided with card slots, and the clamps include a base 4, and the two ends of the base 4 are provided with chucks 3 that match the slots, and the chucks 3 and the base 4 integrated structure.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com