An adjustable displacement spiral sand-carrying lifting device and process

A lifting device and screw technology, which is applied in the field of adjustable displacement screw sand-carrying lifting devices, can solve the problems of no mature technology, unreasonable oil well pump hanging depth, and unsatisfactory application effect, so as to improve the sinking degree , Improve lifting efficiency and reduce the effect of eccentric wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

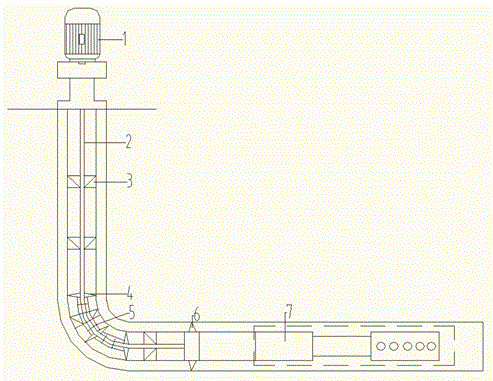

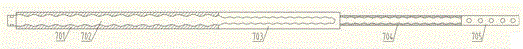

[0024] according to figure 1 and figure 2 As shown, an adjustable displacement screw sand-carrying lifting device includes a driving system 1, a sucker rod 2, and a double-stage spiral ladder lifting system 7 located in the horizontal section. The driving system sucker rod and the double The two-stage spiral ladder lifting system includes a large-displacement all-metal internal helical stator 701, a small-displacement all-metal internal helical stator 704, and a two-stage external helical rotor 702. The large-displacement The all-metal internal helical stator and the small-displacement all-metal internal helical stator are axially connected into one body through the intermediate relief pipe 703. The left half of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com