Retardant insulation block and a method of manufacturing the one-piece

A thermal insulation block, flame retardant and thermal insulation technology, applied in thermal insulation, building structure, building components and other directions, can solve the problems of reduced wall structural strength, large investment, reduced thermal insulation performance, etc. The effect of less and high space applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific features and benefits of the present invention will be clarified by the following description with reference to the accompanying drawings.

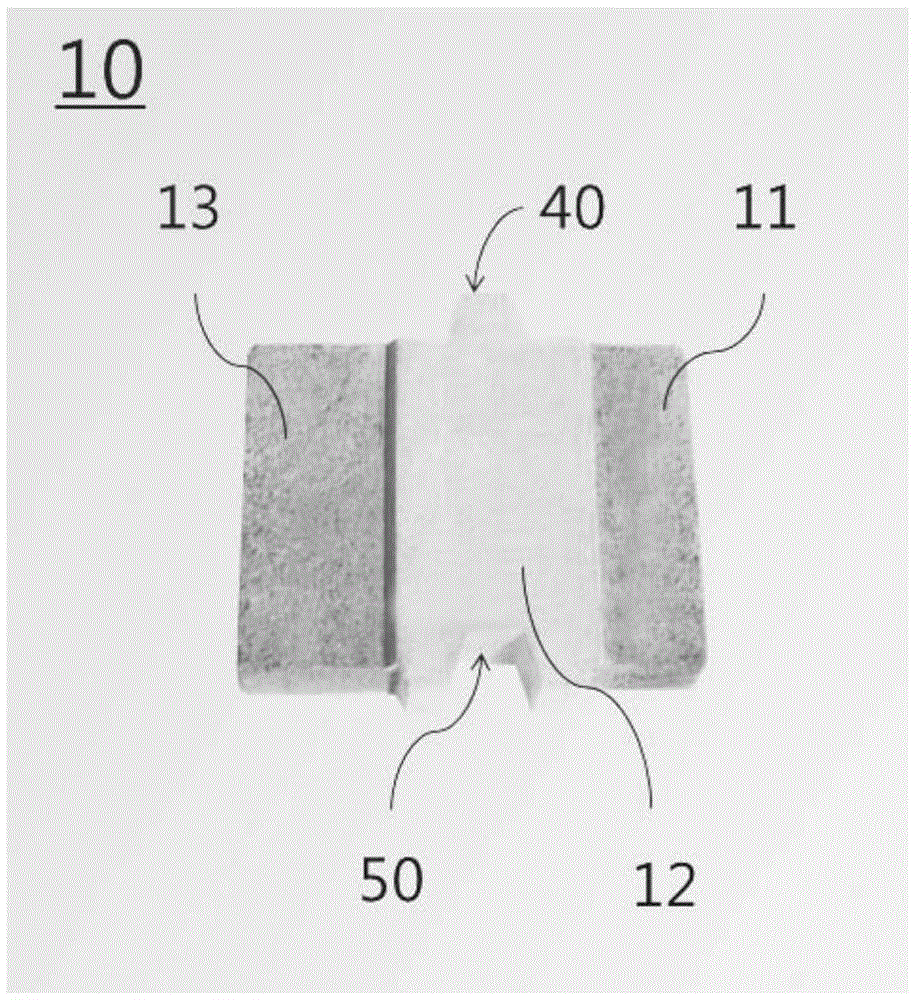

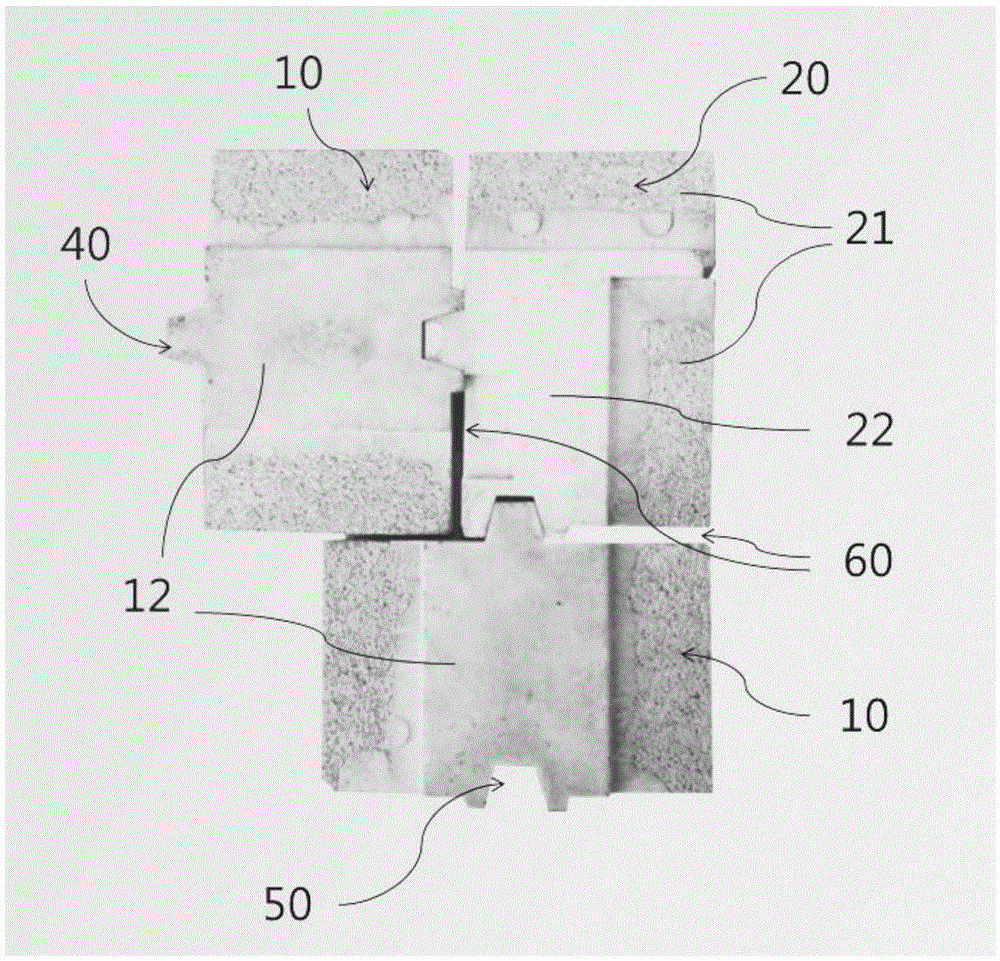

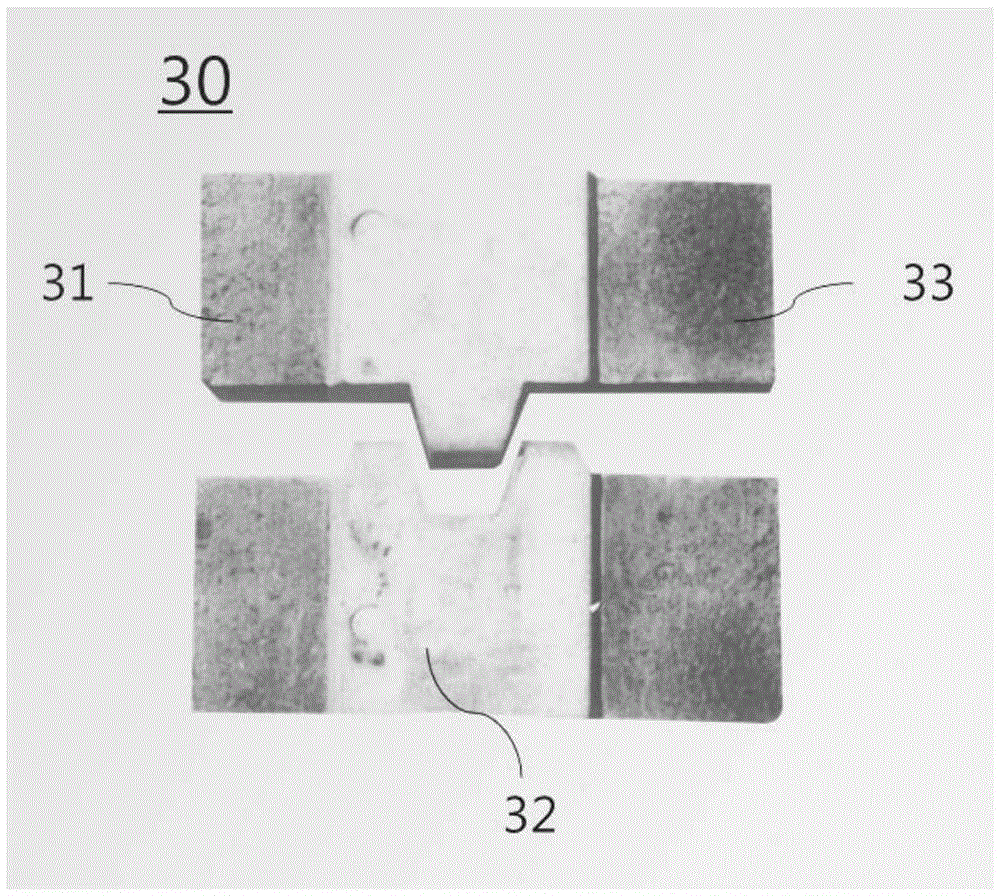

[0054] figure 1 It is the plane view of the straight line portion heat-insulation block of the integrated flame-retardant heat-insulation block of the present invention; figure 2 It is the plan view of the combination of the straight-line thermal insulation block and the corner thermal insulation block of the integrated flame-retardant thermal insulation block of the present invention; image 3 It is a plan view of the cut-off heat-insulation block of the integrated flame-retardant heat-insulation block of the present invention; Figure 4 It is a cross-sectional view showing the masonry shape of the integrated flame-retardant thermal insulation block of the present invention; Figure 5 It is a process diagram showing the manufacturing method of the integrated flame-retardant heat-insulating block of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com