Street floor tile

A technology for floor tiles and streets, applied in the field of floor tiles, can solve problems such as consumption, easy deformation of pedestrians, pollution of pedestrians' pants, etc., and achieves the effect of simple maintenance and prevention of water splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

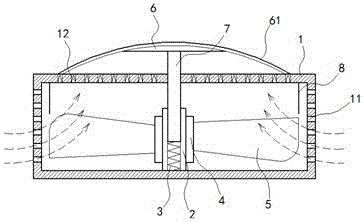

[0013] exist figure 1 In the shown embodiment, the street floor tile includes a rectangular, hollow brick body 1, and a diversion hole 11 is opened on the side wall of the brick body 1; A driven drum 2 is installed, and the driven drum 2 can freely rotate along its own axis, that is, the driven drum 2 is connected with the inner bottom plate of the brick body 1 through a bearing or through a slip ring; The outer wall of the driven drum 2 is provided with toggle teeth, and the inner wall of the driven drum 2 is provided with threads; a reset compression spring 3 is also installed in the driven drum 2; One end of the reset compression spring 3 is fixedly connected to the inner bottom plate of the brick body 1; a ratchet ring 4 matching the toggle teeth is also sleeved outside the driven drum 2, and outside the ratchet ring 4 The impeller 5 is also coaxially sleeved; a step 6 is installed on the top plate of the brick body 1, and an arc-shaped protective cover 61 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com