Galvanization smoke recycling system

A technology of flue gas recovery and plating solution, applied in hot dip plating process, coating, metal material coating process, etc., can solve the problems of increasing energy consumption, increasing investment, etc. The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

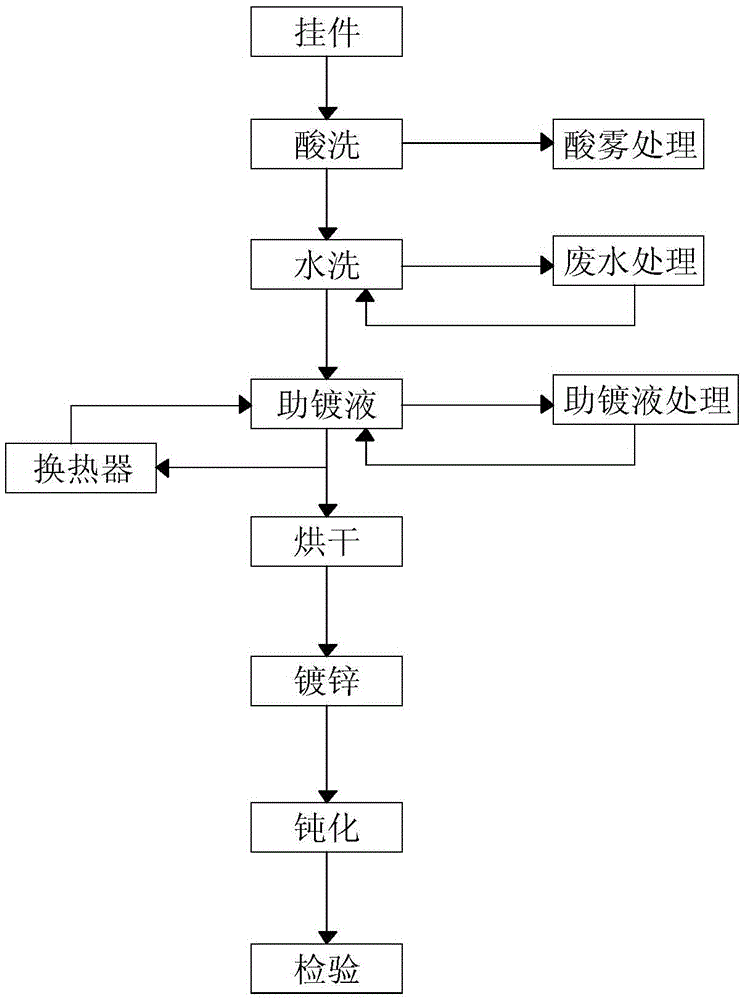

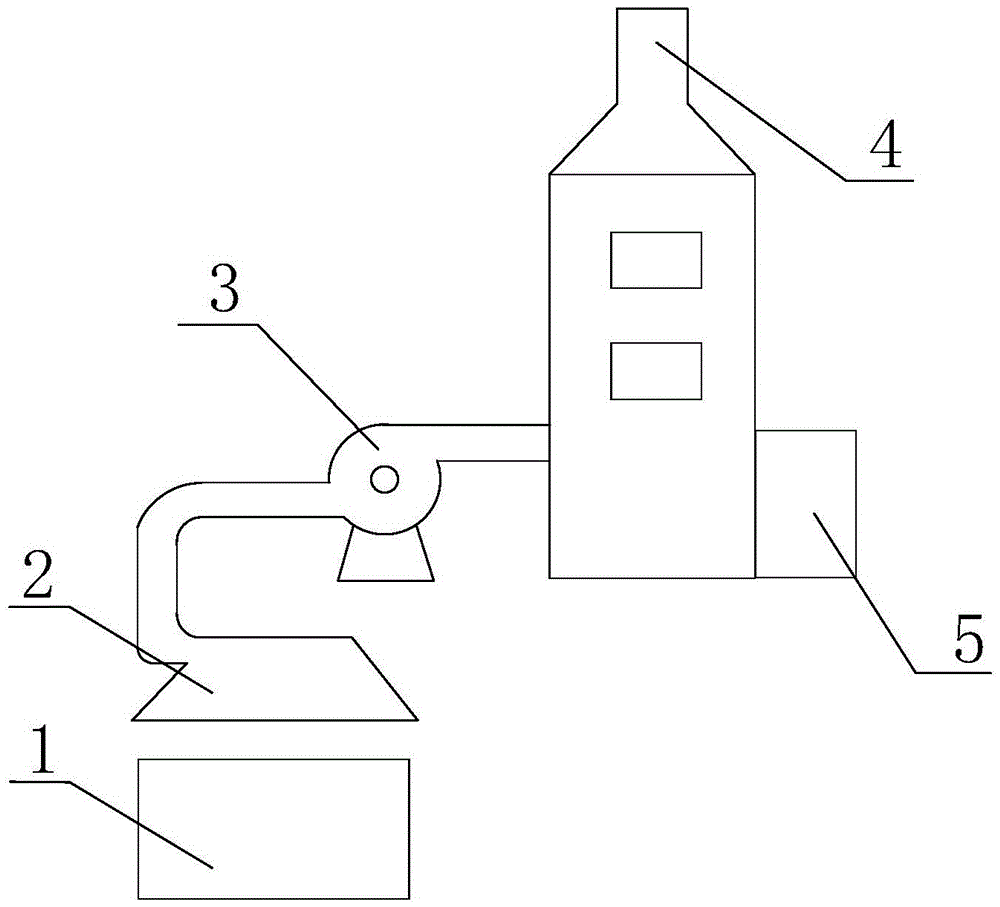

[0015] The invention discloses a galvanized flue gas recovery and utilization system, which ensures the maximum utilization of the waste heat of the flue gas, improves the utilization rate of heat, and is energy-saving and environment-friendly. Under the premise of meeting the production needs, the galvanized pot is guaranteed to be heated evenly, the burning loss of the pot body is reduced, and the service life of the galvanized pot is prolonged. The effective use of waste heat can effectively reduce the labor intensity of workers, reduce energy consumption, and reduce production costs.

[0016] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com