Method for reducing yellowness index of polyglycolic acid

A yellowness index, polyglycolic acid technology, applied in the field of polyglycolic acid manufacturing, can solve the problems of strong yellow coloration and inability to obtain color products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

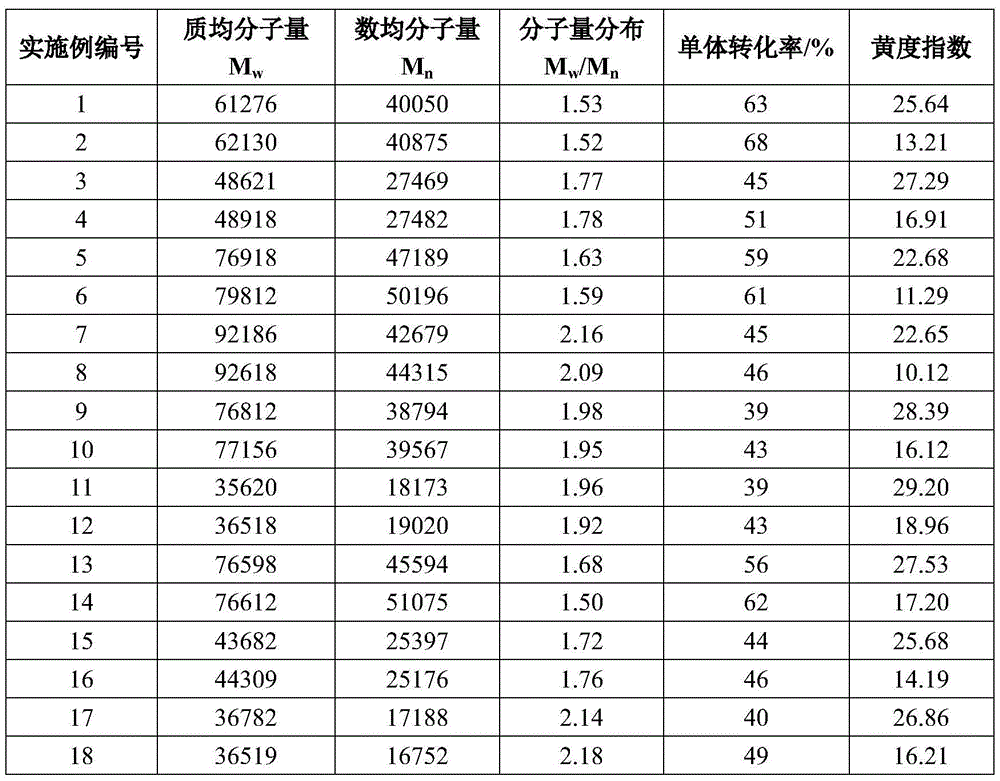

Embodiment 1

[0053] Add 10 g of glycolide to the single-necked flask under nitrogen protection, and inject 4.02 μLSn(Oct) into the reaction flask using a micro-sampling needle 2 . A magnetic stirrer was used to stir the monomer and the catalyst, and the reactants were heated and polymerized in an oil bath, and the polymerization was carried out at 170° C. for 60 min. After the polymerization was completed, the reaction bottle was broken to take out the product. Afterwards, the molecular weight, monomer conversion rate and yellowness index of the polymer were measured, and the relevant results are shown in Table 1.

Embodiment 2

[0055] Add 10g glycolide and 0.00325gPh to the single-necked flask under nitrogen protection 3 P, inject 4.00μLSn(Oct) into the reaction vial using a microsyringe 2 . A magnetic stirrer was used to stir the monomer and the catalyst, and the reactants were heated and polymerized in an oil bath, and the polymerization was carried out at 170° C. for 60 min. After the polymerization was completed, the reaction bottle was broken to take out the product. Afterwards, the molecular weight, monomer conversion rate and yellowness index of the polymer were measured, and the relevant results are shown in Table 1.

Embodiment 3

[0057] Add 10 g of glycolide and 0.00512 g of SnO to the single-necked flask under nitrogen protection. A magnetic stirrer was used to stir the monomer and the catalyst, and the reactants were heated and polymerized in an oil bath, and the polymerization was carried out at 200° C. for 40 min. After the polymerization was completed, the reaction bottle was broken to take out the product. Afterwards, the molecular weight, monomer conversion rate and yellowness index of the polymer were measured, and the relevant results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com