Intensified deep concentration system for high-salt-content industrial wastewater and technology thereof

A technology with high salt content in industrial wastewater, applied in the field of water treatment, can solve the problems of inability to utilize resources, low water recovery rate, high operating cost, etc., and achieve strong economic practicability, low operating cost, and reduce potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

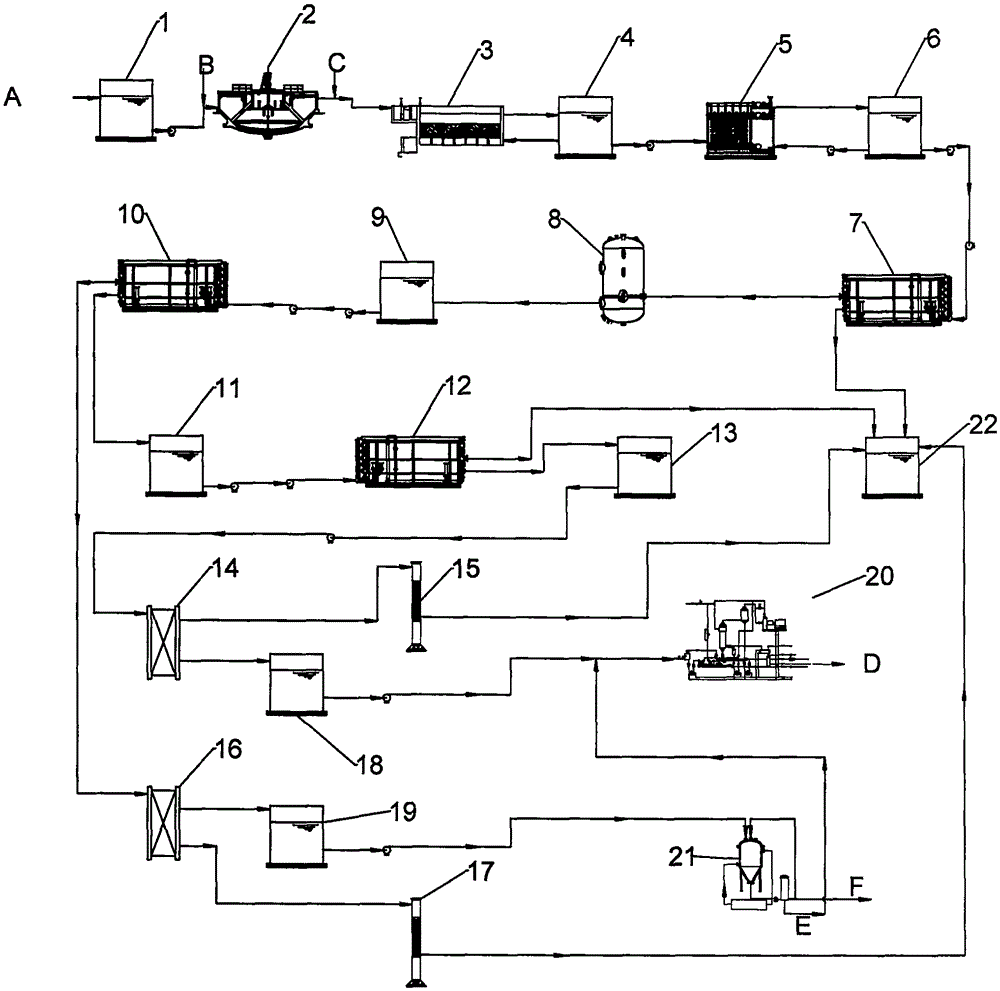

[0032] In conjunction with the accompanying drawings, a full-process treatment system and process of high-salt industrial wastewater with zero discharge of salt and its process are further described in detail. The scope of protection of the present invention is not limited to the following embodiments.

[0033] The average concentration of each pollutant in high-salt industrial wastewater is: COD is 100mg / L, total hardness (calculated as CaCO 3 Calculated) is 1000mg / L, total alkalinity (as CaCO 3 ) is 200mg / L, silicon dioxide is 50mg / L, total dissolved solids (TDS) is 10000mg / L, among them, the concentration of chloride ion is 1800mg / L, and the concentration of sulfate ion is 2900mg / L.

[0034] like figure 1 As shown, a kind of intensive deep concentration system of industrial wastewater with high salt content in the present invention comprises: regulating tank 1, softening sedimentation tank 2, V-type filter tank 3, V-type filter tank water production tank 4, ultrafiltration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com