Bucket elevator used for lifting limestone

A bucket elevator, stone powder technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of low frequency, reduced work efficiency, large fluctuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

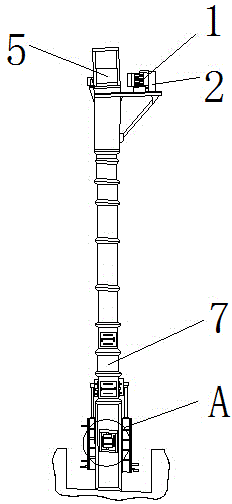

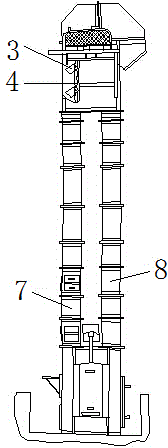

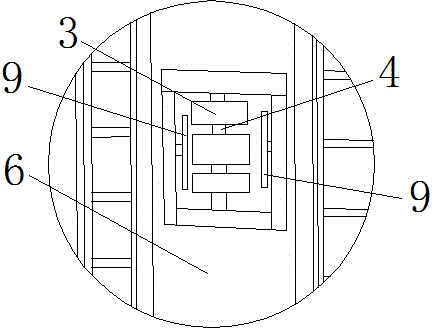

[0024] see Figure 1-Figure 4 , The bucket elevator for lifting stone powder in this embodiment includes a motor 1, a reducer 2, several lifting hoppers 3, a lifting chain 4 and a lifting body, and the motor 1 is connected to the reducer 2. The hoisting chain 4 is installed in the hoisting body, and the hoisting hopper 3 is all installed on the hoisting chain 4. The hoisting body includes an ascending passage 7, a descending passage 8, a feeding device 6 and a discharging device 5.

[0025] A driving runner is arranged in the discharging device 5, and the driving runner is connected with the reducer 2, the motor 1 drives the reducer 2, and the reducer 2 drives the driving runner. Lifting chain 4 is sleeved on the driving runner. During operation, the lifting chain 4 moves between the feeding device 6 , the ascending channel 7 , the discharging device 5 and the descending channel 8 .

[0026] The ascending channel 7 and the descending channel 8 are arranged in parallel, the u...

Embodiment 2

[0036] The bucket elevator for lifting stone powder in this embodiment includes a motor 1, a reducer 2, several lifting hoppers 3, a lifting chain 4, and a lifting body, the motor 1 is connected with the reducer 2, and the lifting chain 4 is installed in the lifting body , The lifting hopper 3 is installed on the lifting chain 4, and the lifting body includes an ascending channel 7, a descending channel 8, a feeding device 6 and a discharging device 5. The ascending channel 7 and the descending channel 8 are arranged in parallel, the upper part of the ascending channel 7 is connected with the discharge device 5 , and the lower part of the ascending channel 7 is connected with the feeding device 6 . The upper part of the descending passage 8 is connected with the discharge device 5 , and the lower part of the descending passage 8 is connected with the feeding device 6 . A driving runner is arranged in the discharging device 5, and the driving runner is connected to the reducer ...

Embodiment 3

[0042] see Figure 5-Figure 6 , the bucket elevator used for lifting stone powder in this embodiment includes a motor 1, a reducer 2, several lifting hoppers 3, a lifting chain 4, and a lifting body, the motor 1 is connected with the speed reducer 2, and the lifting chain 4 is installed on the lifting body Inside, the lifting hopper 3 is installed on the lifting chain 4, and the lifting body includes an ascending channel 7, a descending channel 8, a feeding device 6 and a discharging device 5. The ascending channel 7 and the descending channel 8 are arranged in parallel, the upper part of the ascending channel 7 is connected with the discharge device 5 , and the lower part of the ascending channel 7 is connected with the feeding device 6 . The upper part of the descending passage 8 is connected with the discharge device 5 , and the lower part of the descending passage 8 is connected with the feeding device 6 . A driving wheel capable of driving the lifting chain 4 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com