frame structure of a vehicle

A frame structure and vehicle technology, applied to bicycle frames, bicycle accessories, transportation and packaging, etc., can solve the problems of complex structure, inconvenience, and increased manpower burden, and achieve the effect of simple and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

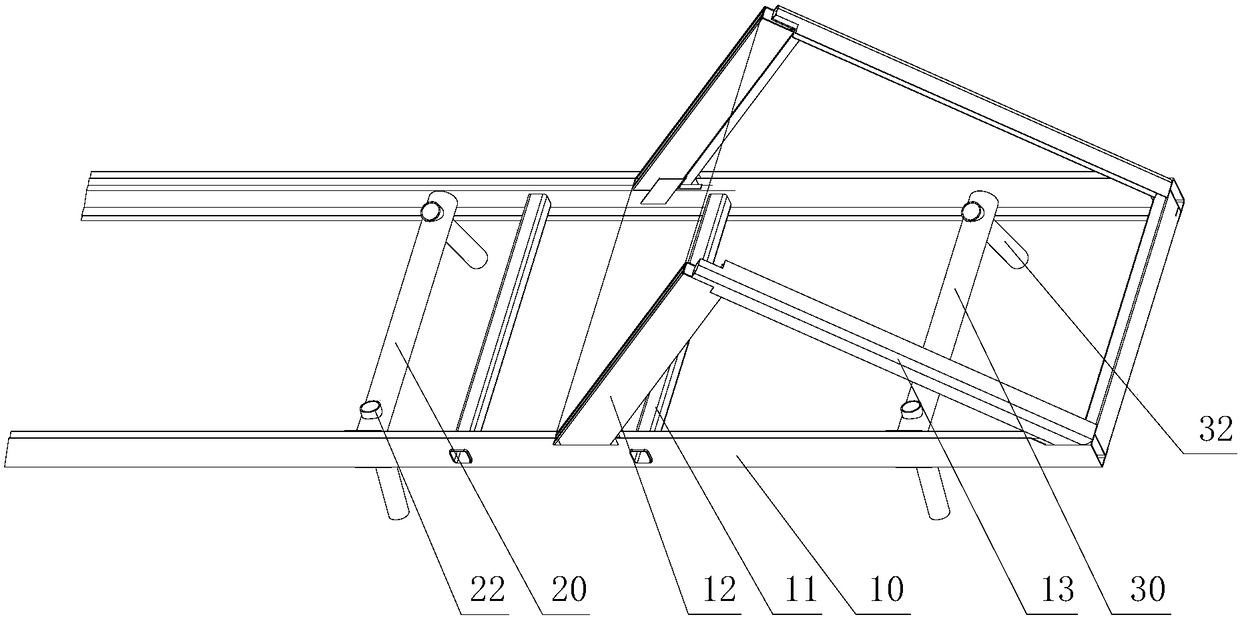

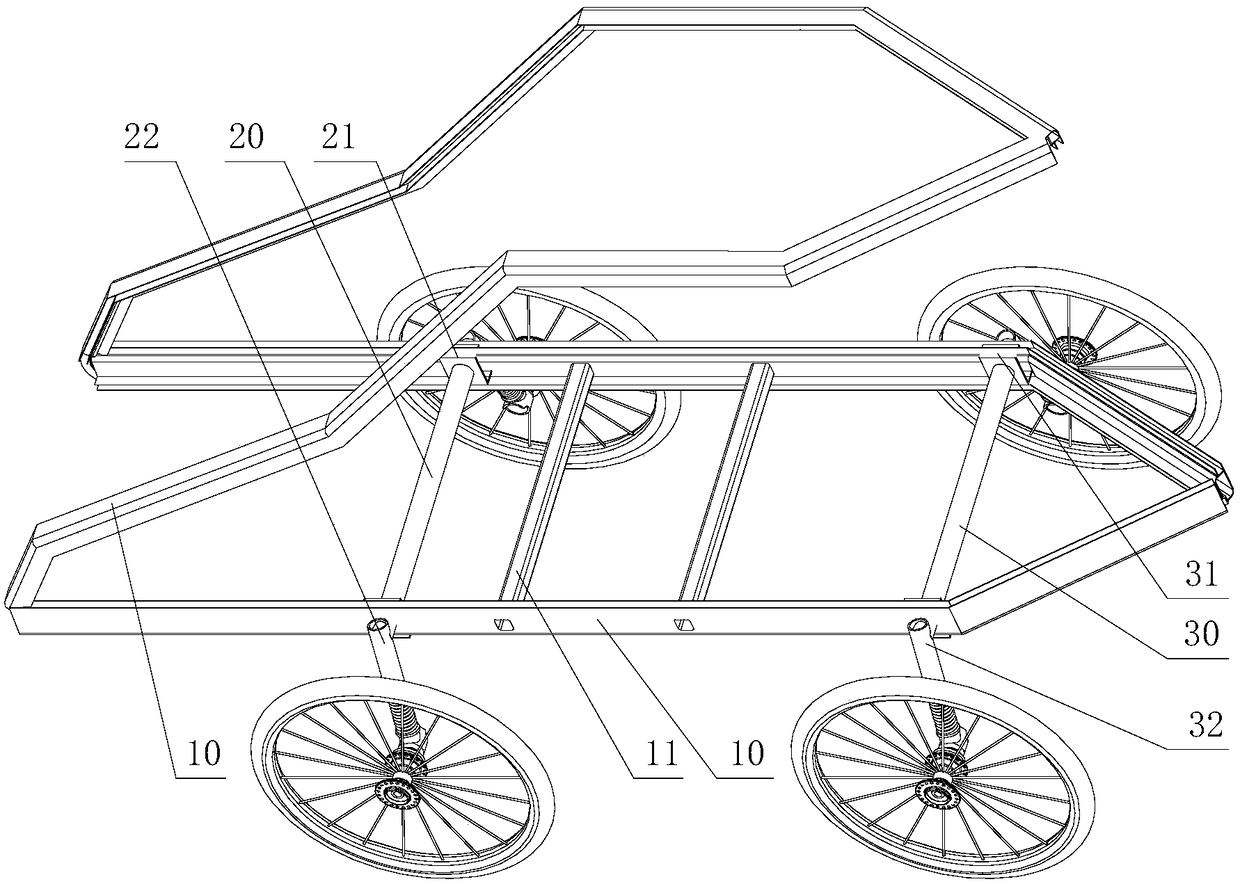

[0039] In order to achieve the purpose of the present invention, as figure 1 As shown, in one of the embodiments of the present invention, a frame structure of a vehicle is provided, which is used for a tricycle or a four-wheel vehicle, including a base main beam frame, including:

[0040] Two main girders 10 are arranged parallel to each other;

[0041] Two beams 11, the two ends of which are respectively connected to the two main beams 10;

[0042] Two back support rods 12, one end of which is arranged on the main beam 10;

[0043] Two rear hemming rods 13, one end of which is respectively arranged on the two main beams 10, and the other end is respectively connected with the two back supporting rods 12, the main beam 10, the back supporting rods 12, and the rear hemming rods 13 form a support on the side structure and a storage space is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com