Independent axle lifting device and method

An independent, axle technology, applied in the automotive field, can solve the problems of poor energy saving, low reliability and high manufacturing cost, and achieve the effect of overcoming low reliability, good versatility and good energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

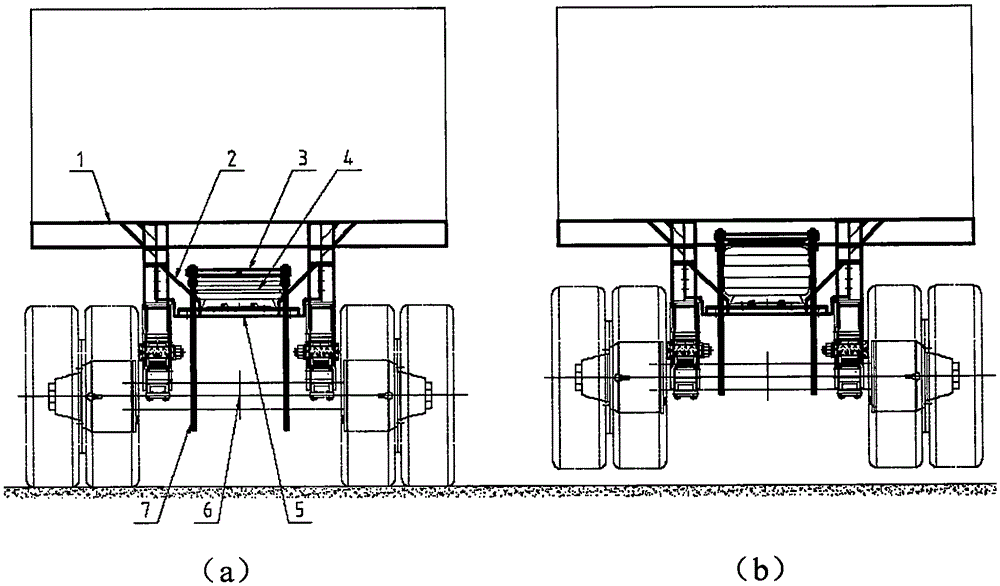

[0025] After a lot of market research and technical demonstration, according to the embodiment of the present invention, such as Figure 1-Figure 4 As shown, an independent axle lifting device is provided. The independent axle lifting device, after a large number of applications, will bring a revolutionary development to Chinese commercial vehicles, greatly reduce transportation costs and achieve energy saving and emission reduction, and contribute a lot to China's air pollution control.

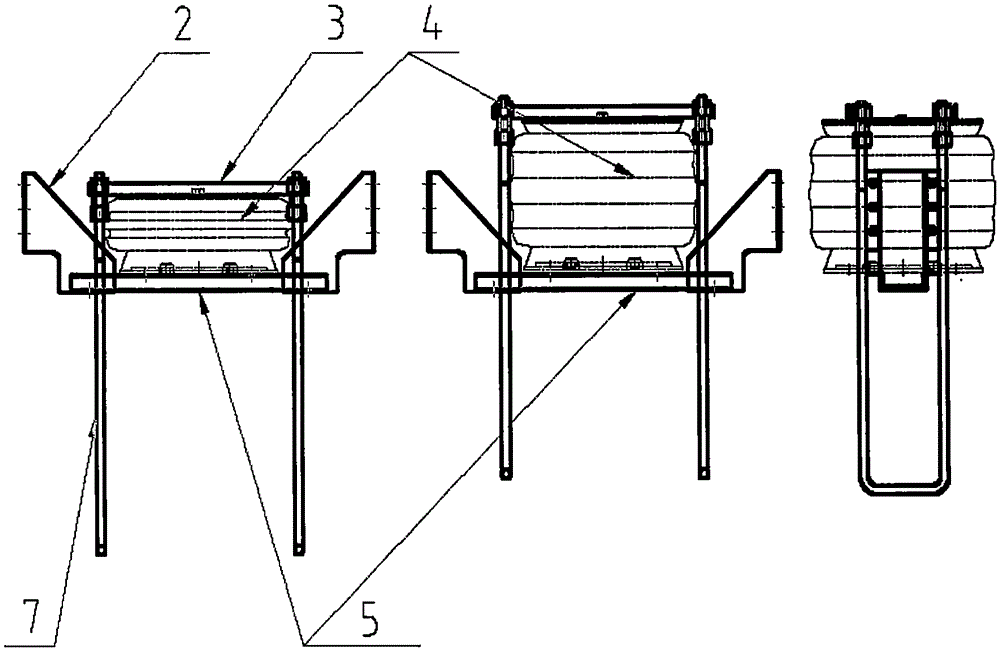

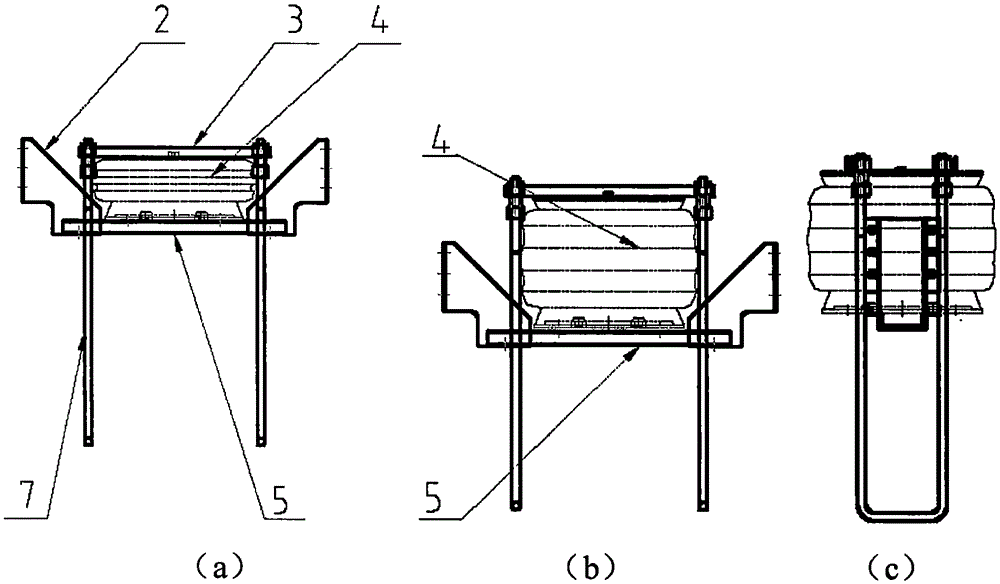

[0026] The independent axle lifting device and method of the present embodiment include: lifting bracket 2, air bag upper support 3, air bag 4, air bag lower support 5, U-shaped b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com