Production line machining equipment for packing boxes

A processing equipment and packaging box technology, applied in the direction of packaging, transportation and packaging, box production operations, etc., can solve the problems of reducing efficiency, increasing production costs, and wasting time, so as to reduce manpower input, save time, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

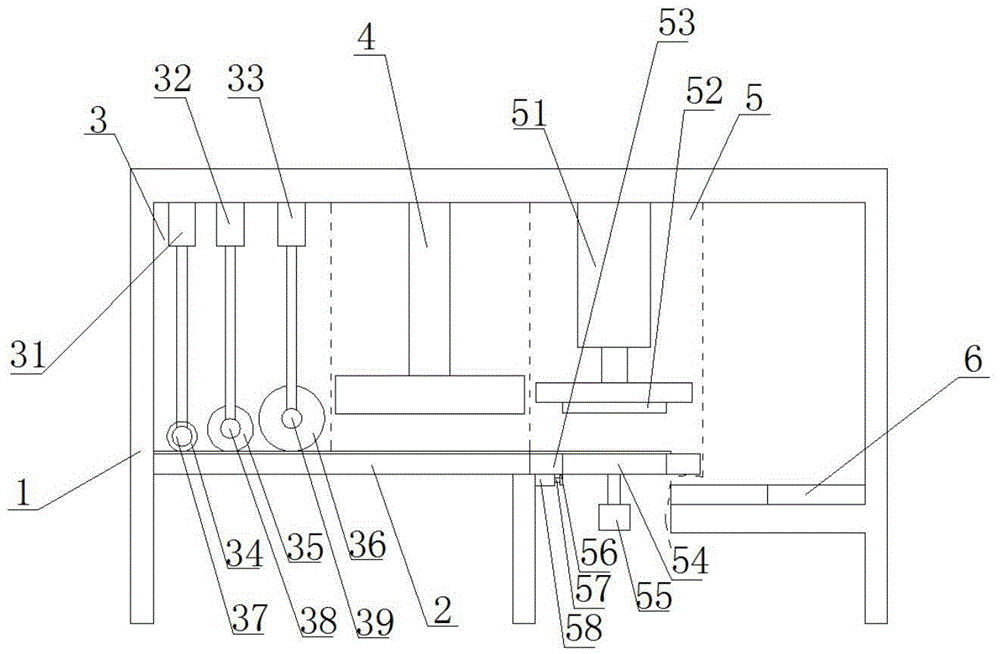

[0015] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a packaging flow processing equipment proposed by the present invention.

[0016] refer to figure 1 , a packaging flow processing equipment proposed by the present invention includes a frame 1, a transmission mechanism 2, a film covering mechanism 3, a drying mechanism 4, a punching and cutting mechanism 5 and a hemming mechanism 6, and the transmission mechanism 2 is fixed on the frame 1 On the upper part, there is a conveying surface, the conveying surface is arranged horizontally, and the laminating mechanism 3, the drying mechanism 4, the punching and cutting mechanism 5 and the hemming mechanism 6 are sequentially fixed on the frame 1 along the conveying direction of the conveying mechanism 2, and The laminating mechanism 3 and the stamping mechanism 4 are located above the conveying surface.

[0017] The laminating mechanism 3 includes a glue applying part, a film covering part and a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com