Flattop chamfering and cutting device

A cutting device and chamfering technology, applied in the field of steel pipe manufacturing, can solve the problems of inaccurate positioning of tools and floating flanges, easy generation of ripples on the vibrating groove of the tool shank, which is not conducive to realizing cutting automation, etc., and achieves compact structure, low cost, Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

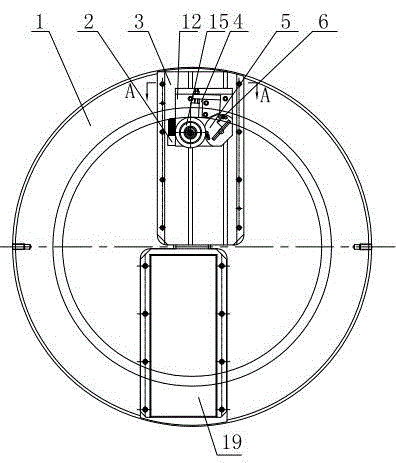

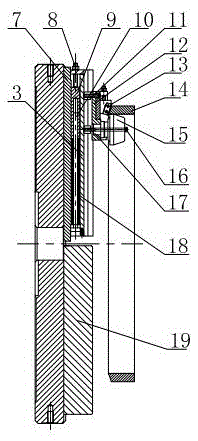

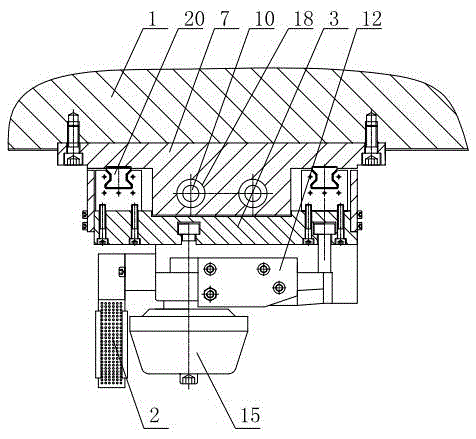

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 , figure 2 and image 3 As shown, the flat head chamfering cutting device of this embodiment includes a cutter head 1, and a cutting device and a balance weight 19 are symmetrically installed on the cutter head 1. Linear guide rails 20 are respectively installed at both ends of the base plate 7, and a floating seat 3 is installed through the linear guide rails 20 on the base plate 7. There are also holes symmetrically in the middle of the base plate 7. Disc springs 18 are respectively installed in the holes, and guide rods 10 are installed in the middle of the disc springs 18. , a guide block 9 is installed on the top of the guide rod 10, and a pre-tightening screw 8 is installed on the top of the guide block 9; the floating seat 3 slides along the linear guide rail 20, and a T-shaped groove is opened on the floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com