A kind of autonomous sorting method of fabric sorting robot

A technology of robots and fabrics, which is applied in the field of autonomous sorting of fabric sorting robots, and can solve problems such as inability to autonomously sort flexible fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0055] The present invention takes a four-degree-of-freedom robot whose control system is in the form of a PC and a motion control card as an example.

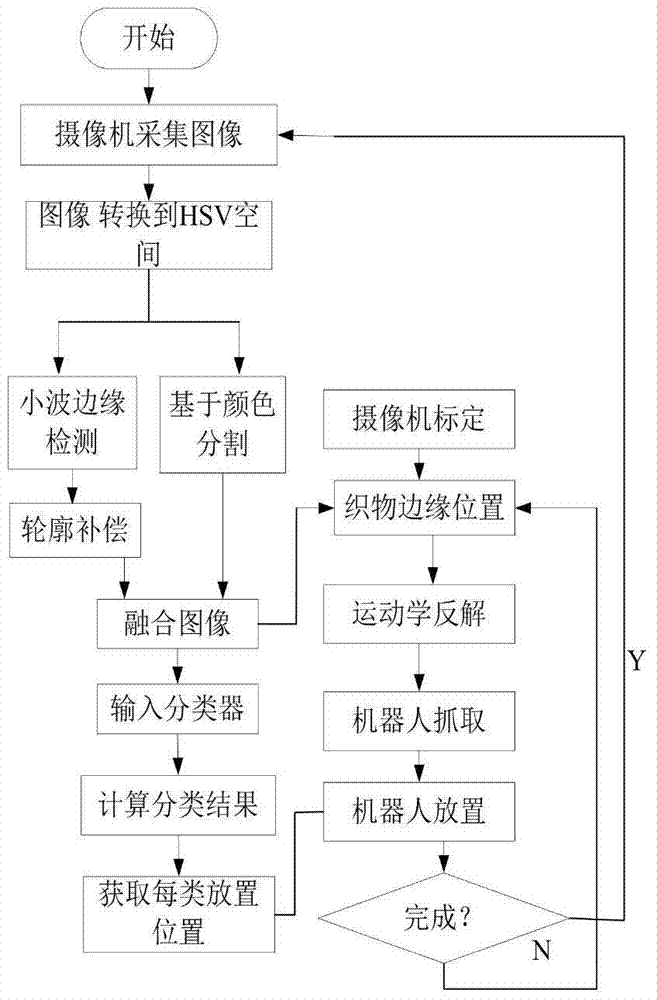

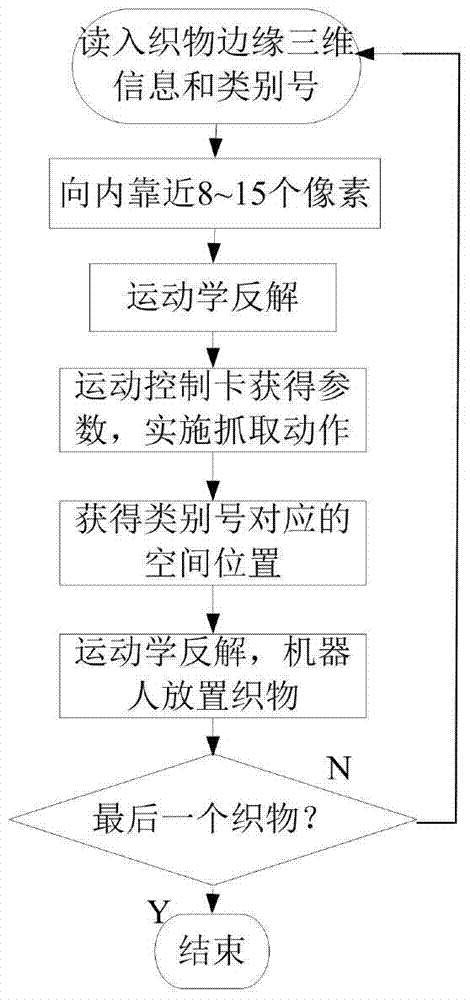

[0056] A kind of autonomous sorting method of fabric sorting robot of the present invention, flow process is as follows figure 1 As shown, follow the steps below:

[0057] Step 1. First calibrate the binocular camera installed above the robot; the calibration adopts the classic Zhang Zhengyou calibration method. For the images collected by binocular vision, 6 points are taken for each image to calculate the internal and external parameters of the camera;

[0058] Step 2, collect the fabric image signal through the binocular camera installed above the robot, and then transmit it to the image processing unit on the PC in real time online;

[0059] Step 3, the image processing unit positioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com