Panty-hose with V-shaped crotch and production method of panty-hose

A production method and technology of pantyhose, applied in V-shaped crotch pantyhose and its production field, can solve problems such as discomfort and lack of protective function of human skin, and achieve the goal of improving aesthetics, excellent protective function, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

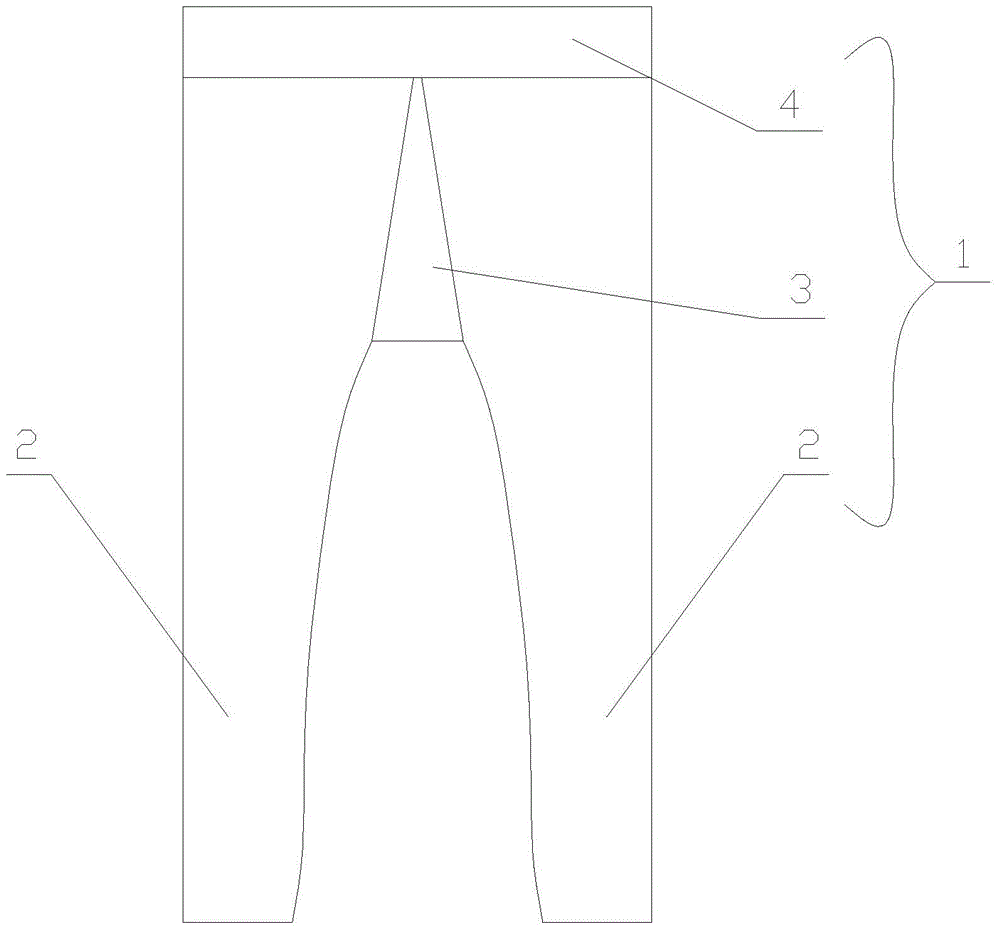

[0019] like figure 1 Shown, a kind of V-shaped crotch pantyhose, comprises pantyhose main body 1, and the front and back of the crotch of this pantyhose main body 1 is inverted V shape, and this pantyhose main body 1 comprises two sock tubes 2 and crotch portion 3, wherein the crotch 3 is an independently formed rhombus structure, and the crotch 3 and the two sock tubes 2 are connected together by splicing. By designing the crotch 3 as an independently formed rhombus structure, and the crotch 3 and the two sock tubes 2 are connected together by splicing, to realize the front and rear uniformity of the crotch of the pantyhose main body 1 after forming. It is an inverted V shape, so the design can make the whole crotch 3 have no se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com