Radiator tank for a motor vehicle

A technology for motor vehicles and water tanks, applied in vehicle components, heating/cooling equipment, air handling equipment, etc., can solve problems such as large resistance of steering devices, and achieve the effect of reducing resistance, reducing energy consumption, and avoiding flow interruptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

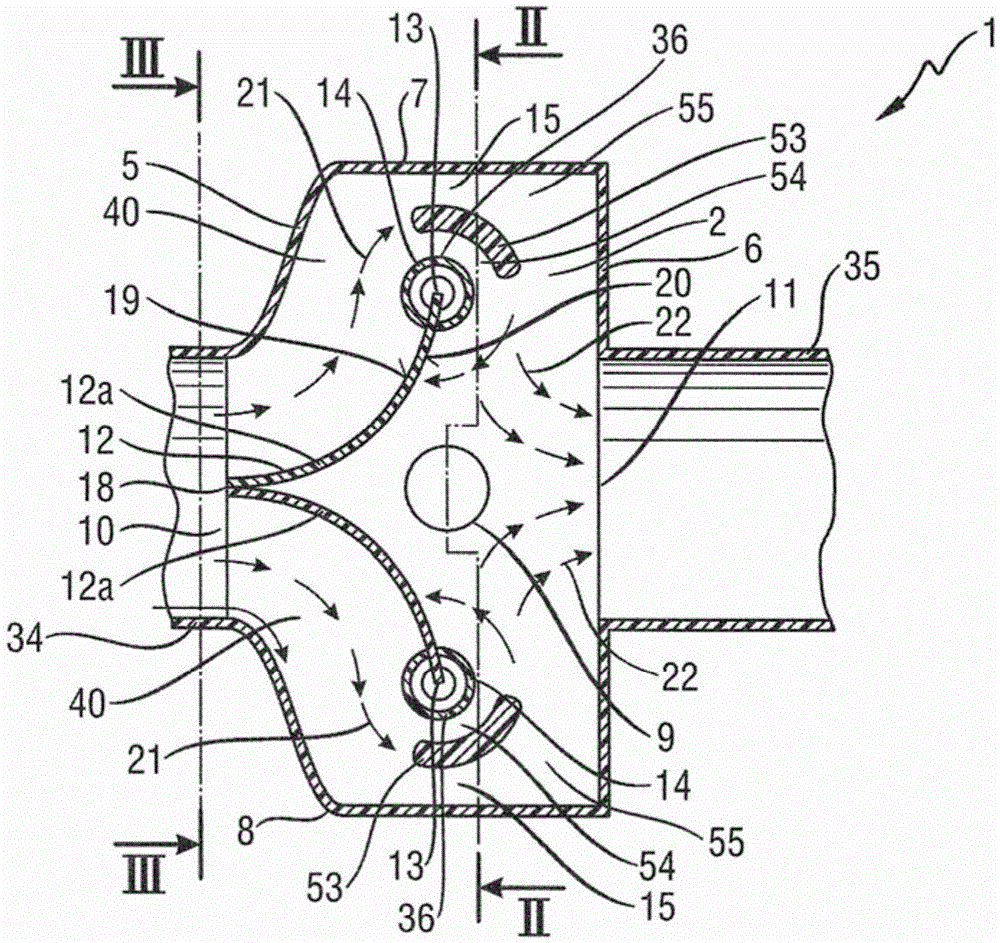

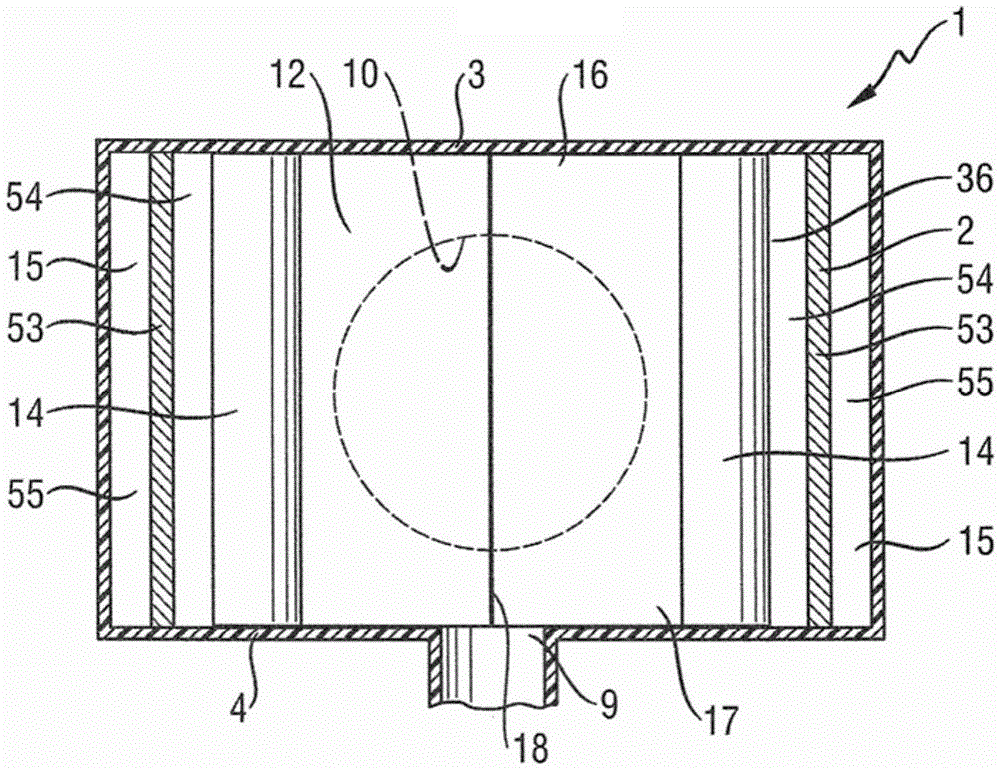

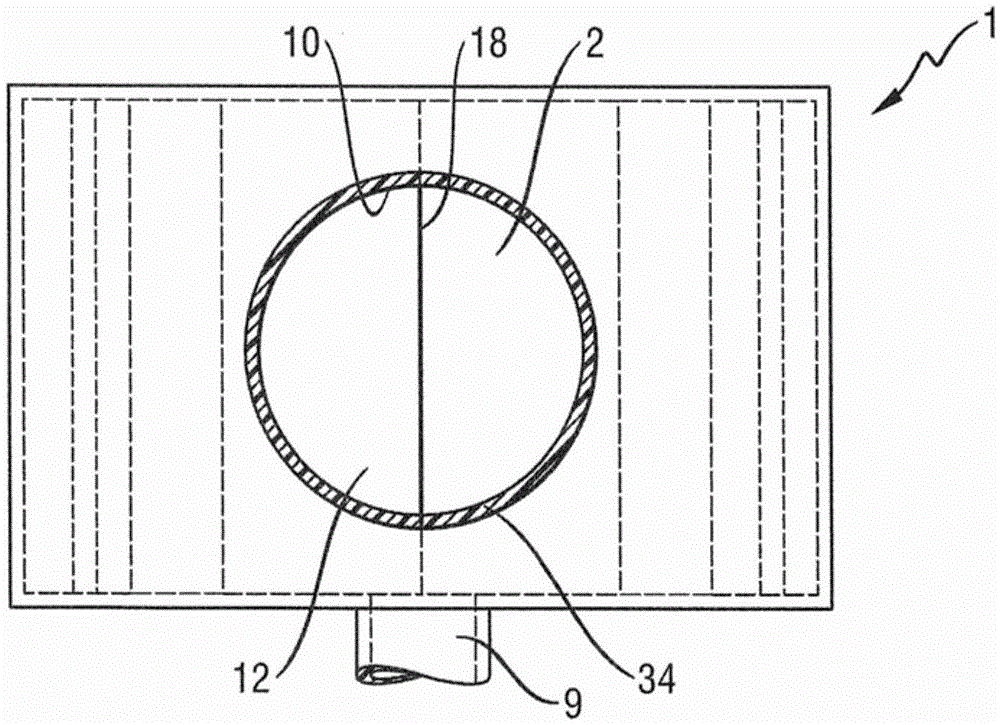

[0046] exist Figures 1 to 4 The cistern 1 shown in has a deflection chamber 2 with a top wall 3 , a bottom wall 4 , a front wall 5 , a rear wall 6 and two side walls 7 and 8 running essentially parallel to one another. The front wall 5 has an air inlet 10 at which sucked-in fresh air can be introduced into the deflection chamber 2 . The front wall 5 is connected via a pipe 34 to a suction opening (not shown here), which is arranged, for example, below the windshield and is covered by a grid (not shown here). The tube 34 can be circular in cross-section as shown. However, the cross section of the tube 34 forming the inlet connection can also have another shape, for example it can be rectangular. The air inlet 10 can also extend over the entire height of the front wall 5 . exist figure 1 , the air thus flows from left to right into the deflection chamber 2 . The transition regions between the tube 34 and the front wall 5 and between the front wall 5 and the side walls 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com