Centrifugal drier

A dryer, centrifugal technology, used in centrifuges, dryers, drying solid materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

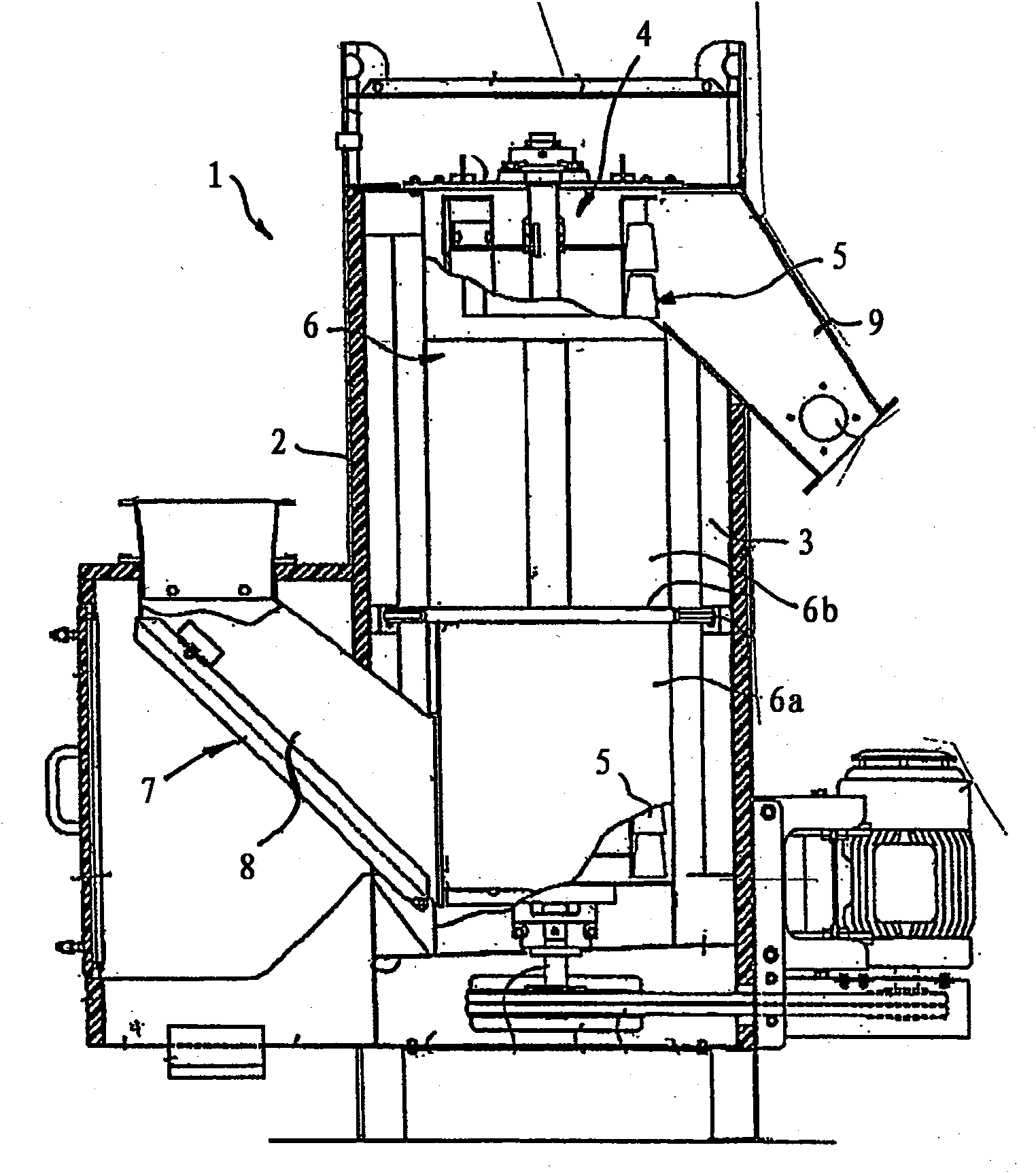

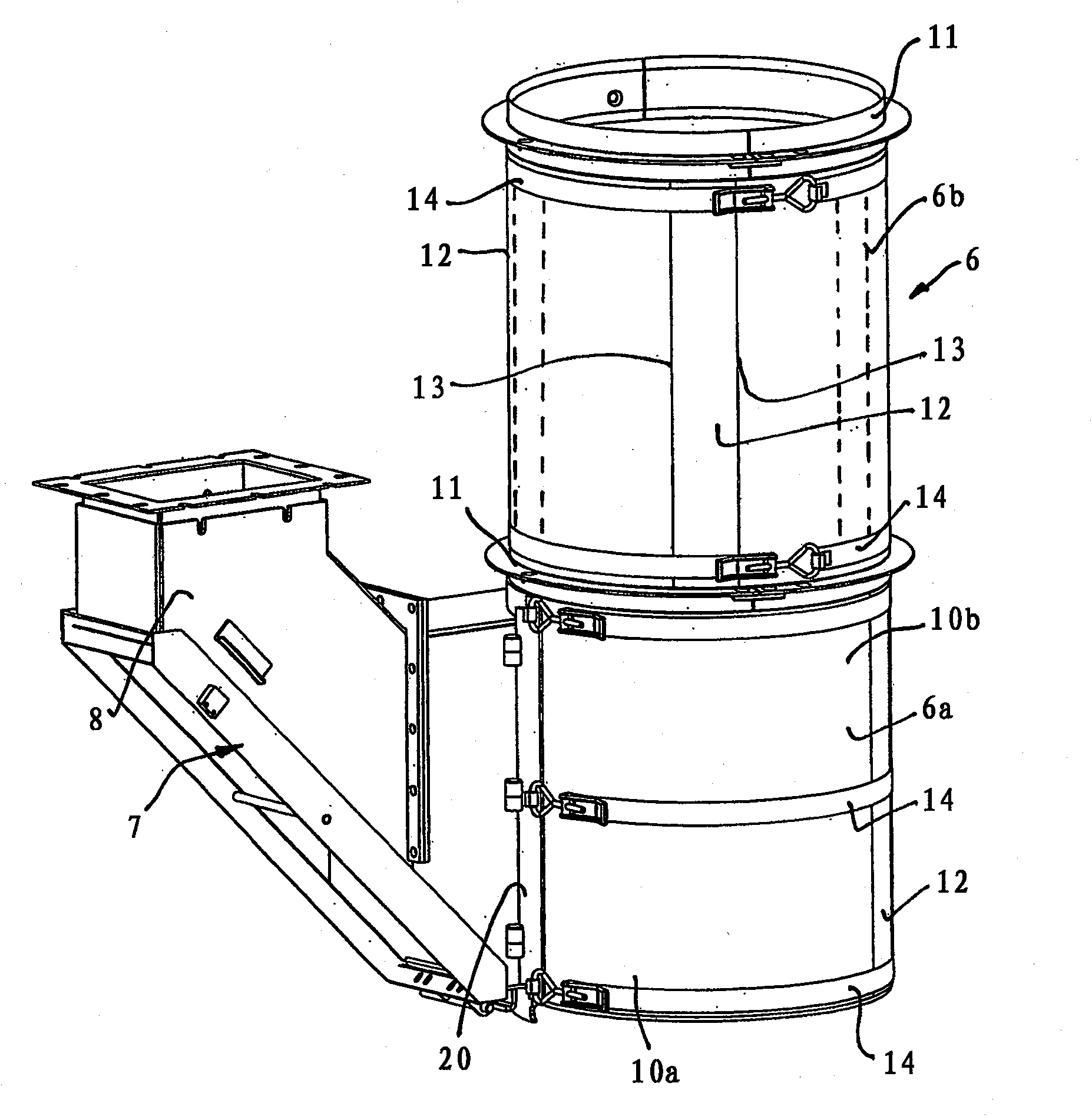

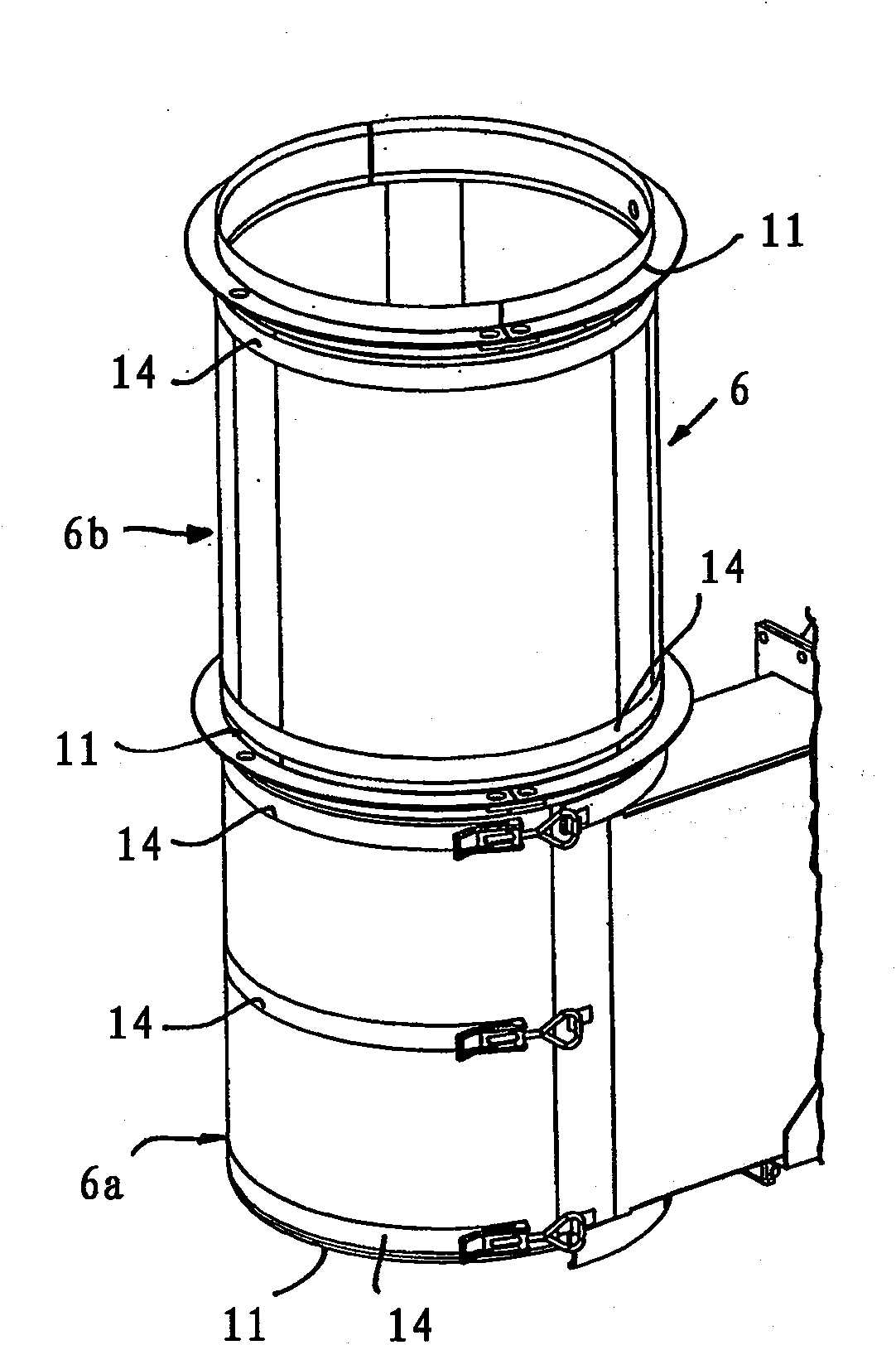

[0031] figure 1 The illustrated centrifugal dryer 1 comprises an overall—roughly speaking—cylindrical housing 2 , which is closed by a door provided on the housing side, through which the interior 3 of the housing 2 is accessible. Arranged in the interior 3 of the housing 2 is a rotor 4 , which can be driven in rotation about a vertical axis of rotation by means of a drive motor (not shown in detail). Such as figure 1 As shown, the rotor 4 includes a plurality of vane-like conveying elements 5 which protrude from the central axis of rotation and guide the granulate / process water mixture in the centrifugal dryer 1 from the bottom up into the inner space 3 of the housing. The conveying elements 5 protruding from the axis of rotation can in principle be designed in different ways, for example in the form of planar, curved or curved plates or in the form of helically curved parts or other shaped conveying elements.

[0032] In this respect, the rotor 4 is surrounded in the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com