Dry etching device

A dry etching and annular protection technology, applied in the manufacture of discharge tubes, electrical components, semiconductor/solid-state devices, etc., can solve the problems of uneven etching of the wafer to be etched or the substrate 4, reduction of plasma energy, etc., and increase the normal operation. time, reduced maintenance costs, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

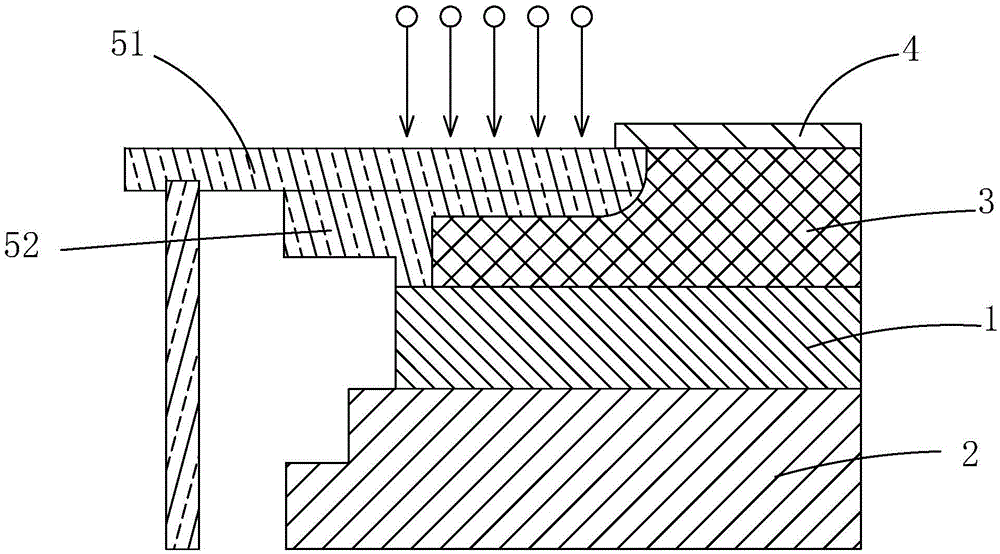

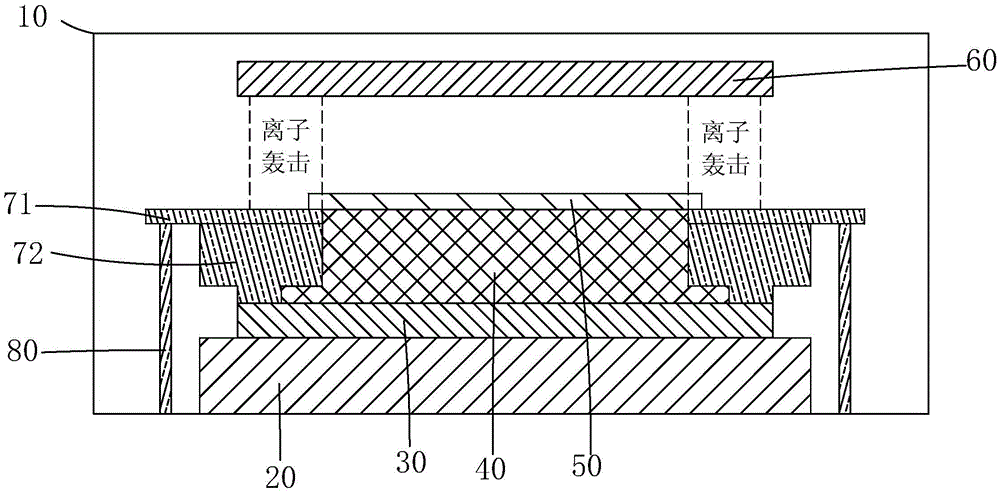

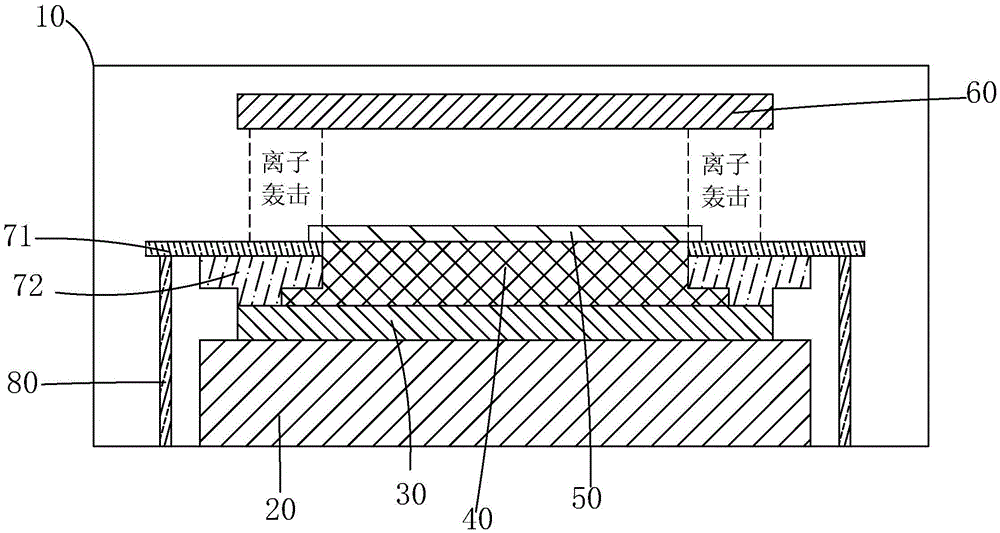

[0026] The invention provides a dry etching device. figure 2 Shown is the first embodiment of the dry etching device of the present invention, comprising: a vacuum chamber 10, an insulating plate 20 disposed in the vacuum chamber 10, a lower electrode plate 30 disposed on the insulating plate 20, and a The electrostatic adsorption platform 40 used to carry the substrate 50 to be etched on the lower electrode plate 30, the upper electrode plate 60 arranged at a distance from the lower electrode plate 30, and the edge protection plate 71 flush with the upper surface of the electrostatic adsorption platform 40 , and an annular protection plate 72 arranged between the edge protection plate 71 and the lower electrode plate 30 to cover the outer periphery of the lower electrode plate 30 and the electrostatic adsorption platform 40 .

[0027] The edge protection plate 71 at least completely covers the ring protection plate 72 , that is, the extension length of the edge protection pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com