Brushless excitation-type generator set rotation diode detection system and method thereof

A technology of rotating diodes and generating sets, which is applied in the electric power field, can solve the problems of low maintainability, and achieve the effects of friendly interface, high intelligence, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

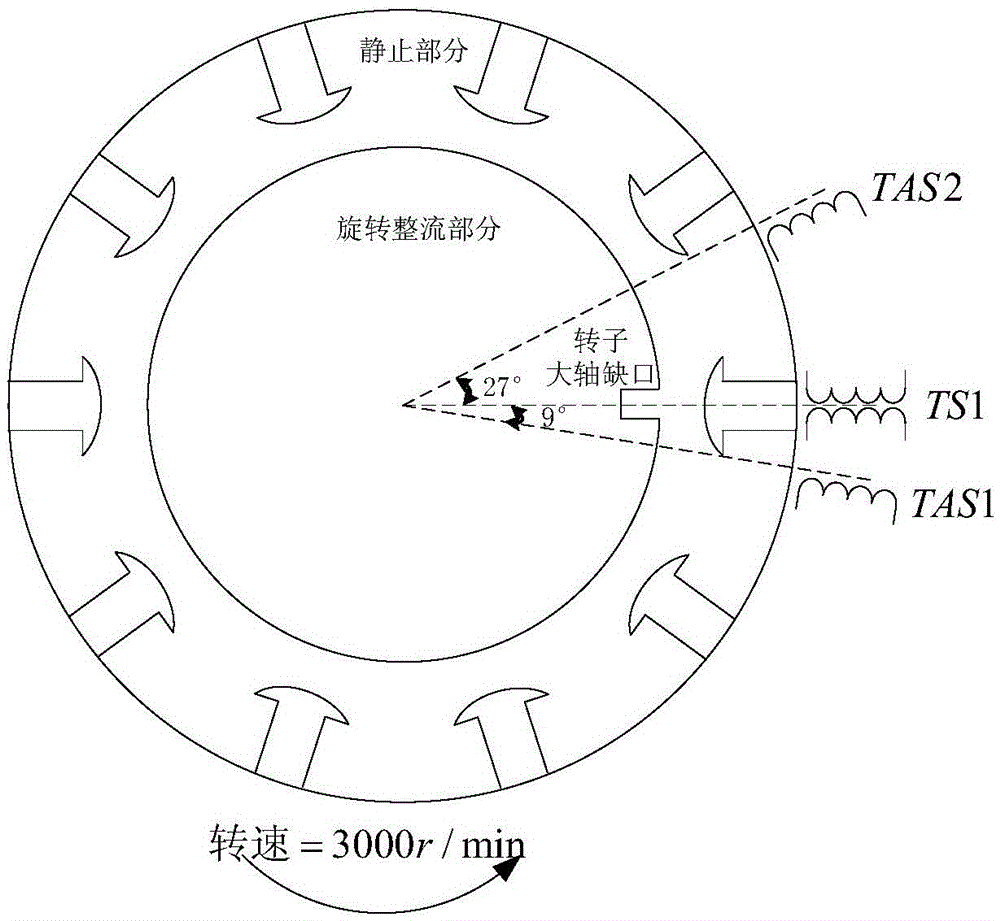

[0038] Such as figure 2 As shown, it is a structural diagram of an embodiment of a rotating diode detection system for a brushless excitation type generator set provided by the present invention, as shown in figure 2 As shown, it includes a large shaft notch detection coil TS1, a first current induction detection coil TAS1, a second current induction detection coil TAS2 and a state detection module, wherein the large shaft notch detection coil TS1 is arranged on the periphery of the static part of the generator set for When the large shaft notch rotates to the corresponding position of the large shaft notch detection coil TS1, an induction signal is generated; the first current induction detection coil TAS1 and the second current induction detection coil TAS2 are respectively arranged on the periphery of the static part of the generator set, and are located on the large shaft On both sides of the axis notch detection coil TS1, the first current induction detection coil TAS1 ...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that it also includes the host computer humanized interface nestools, which is connected with the state detection module, such as Figure 4 As shown, it is used for the location of the faulty rotating diode branch, the I section alarm and II section fault display and the function of limiting the output of the excitation system. According to the fault degree of the rotating rectification system, the excitation regulator is used to limit the output of the excitation system of the generator to ensure the safe operation of the generator set. .

[0061] Implementing the embodiment of the present invention has the following beneficial effects:

[0062] (1) Improve the direct detection method without adding sensors. It is applied to the rotating rectification excitation type generator set. The layout position of the detection coil depends on the structure of the generator body, which can realize positioning, alarm, fau...

Embodiment 3

[0067] This embodiment provides a method for detecting the rotating diode of a brushless excitation generator set based on the rotating diode detecting system of Embodiment 1, such as Figure 5 shown, including steps:

[0068] S101. The state detection module obtains the induction signal of the large shaft notch detection coil TS1, the induction signal of the first current induction detection coil TAS1, the induction signal of the second current induction detection coil TAS2 and the detection input signal of the external input rotating diode, and converts is a square wave signal;

[0069] S102. Judging whether the state detection module has received the detection input signal of the external input rotating diode, and judging whether the first self-test fault and the second self-test fault occur according to the induction signal of the large shaft gap detection coil TS1, wherein, the first self-test fault The detection fault is that the time stamp of the induction signal of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com