System and method for online automatically detecting defects on glass surface of touch screen

An automatic detection and glass surface technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of slow detection speed, high labor cost, human eye fatigue and other problems of visual method, so as to improve the detection efficiency and detection accuracy , high detection accuracy and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

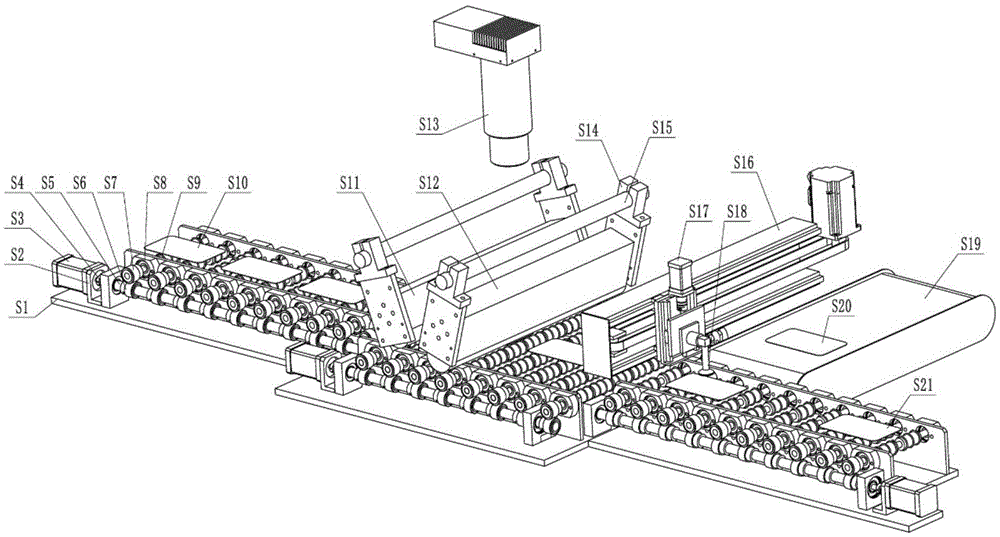

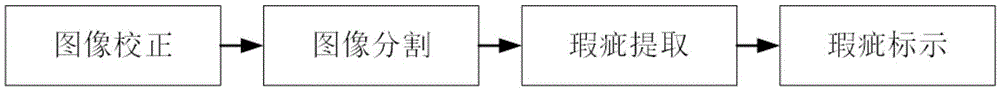

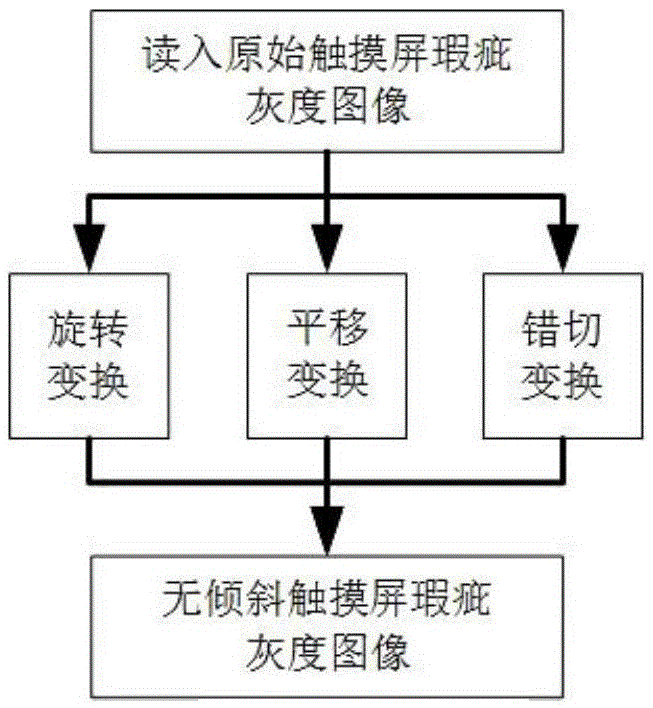

[0062] The surface defect detection test is carried out for the touch screen mobile phone cover plate used in mobile phones. The size of the tested mobile phone cover is 63.3 (mm) × 129.6 (mm), and the original grayscale image of the mobile phone cover is obtained after scanning, such as Figure 7 As shown, the collected image contains not only the grayscale image of the mobile phone cover, but also some useless redundant information. In order to improve the speed of subsequent image feature extraction, less data processing is required. Therefore, the image can be corrected through transformations such as rotation, translation, and miscutting, as well as edge extraction, to obtain an image that only contains the mobile phone cover, such as Figure 8 shown. Since the physical position of the feature area of the mobile phone cover relative to the frame of the mobile phone is relatively fixed, the position of the frame image can be extracted according to the corrected image, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com