Multi-parameter pneumatic comprehensive measurement device for water pump shell

A comprehensive measurement and multi-parameter technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of low efficiency, low precision, inaccurate measurement, etc., and achieve the effect of high efficiency, high precision and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

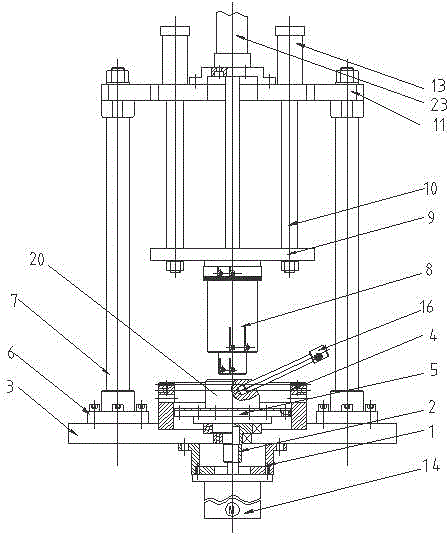

[0018] The specific embodiment: below in conjunction with accompanying drawing, the best embodiment of the present invention is described in detail:

Embodiment

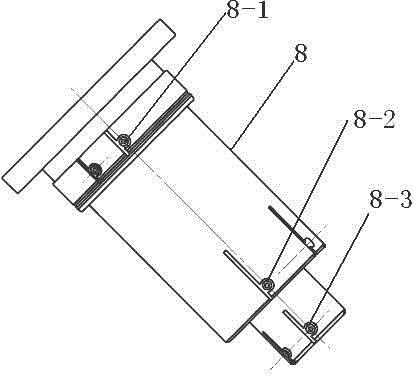

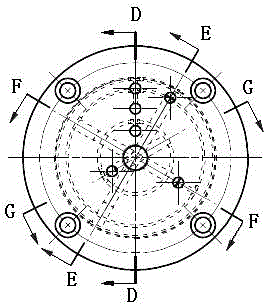

[0019] Embodiment: A multi-parameter pneumatic comprehensive measurement device for water pump housing (see figure 1 ), which includes a worktable 3, a gear motor 14 connected to the bottom of the worktable 3 through a motor base 1, a motor drive shaft 2 connected to the turntable 5, a lower probe body 4 connected to the worktable 3, and an upper probe body 8 connected to the lifting plate 9 connection, the lifting plate 9 is connected with the top plate 11 through the guide column 10 and the guide sleeve 13, the upper measuring head body 8 can be lifted up and down through the cylinder 23, and the top plate 11 is connected with the work table 3 through the support shaft 7 and the shaft seat 6. Upper probe body 8 (see Figure 2-Figure 7 ) are respectively provided with 3 inner diameter coaxiality injection holes, i.e. the first inner diameter coaxiality injection hole 8-1, the second inner diameter coaxiality injection hole 8-2, the third inner diameter coaxiality injection ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com