Manhole cover positive and negative pressure performance test bench and manhole cover positive and negative pressure performance test method

A manhole cover and test bench technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of lack of devices, errors in the manufacturing and installation process, affecting the use effect of ex-factory products, etc. The effect of reliable operation, high reliability and stable pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings.

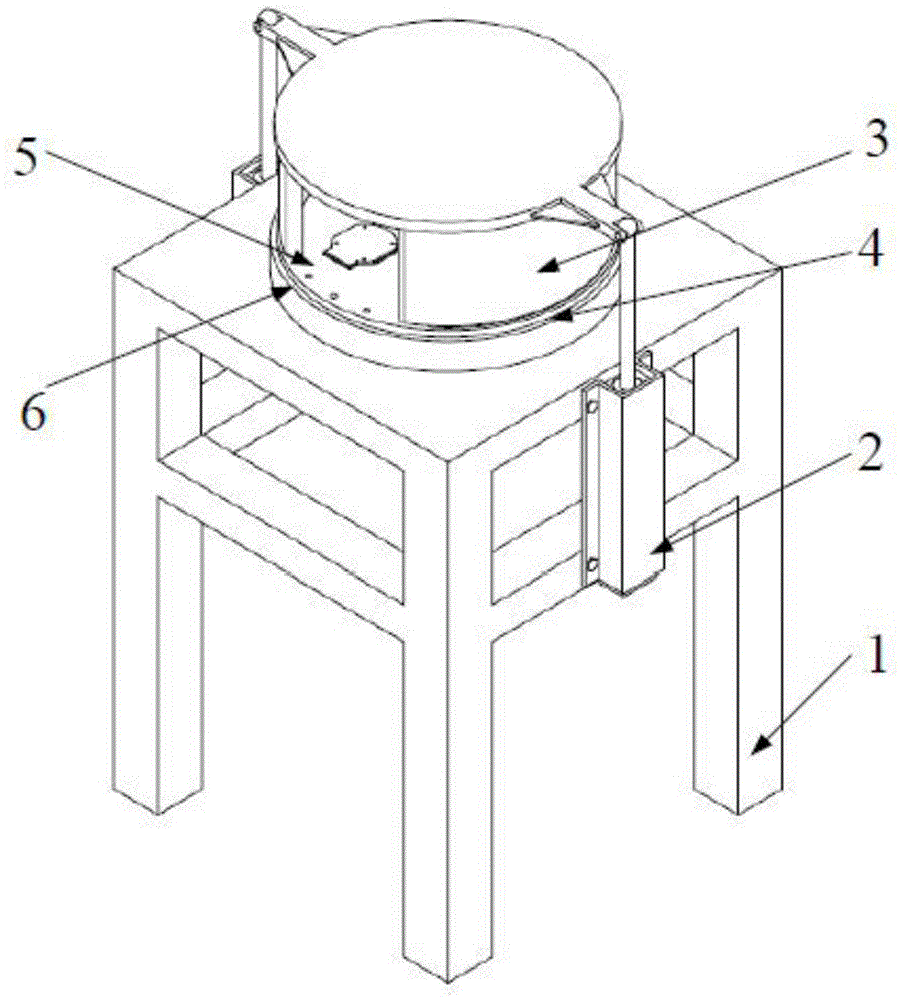

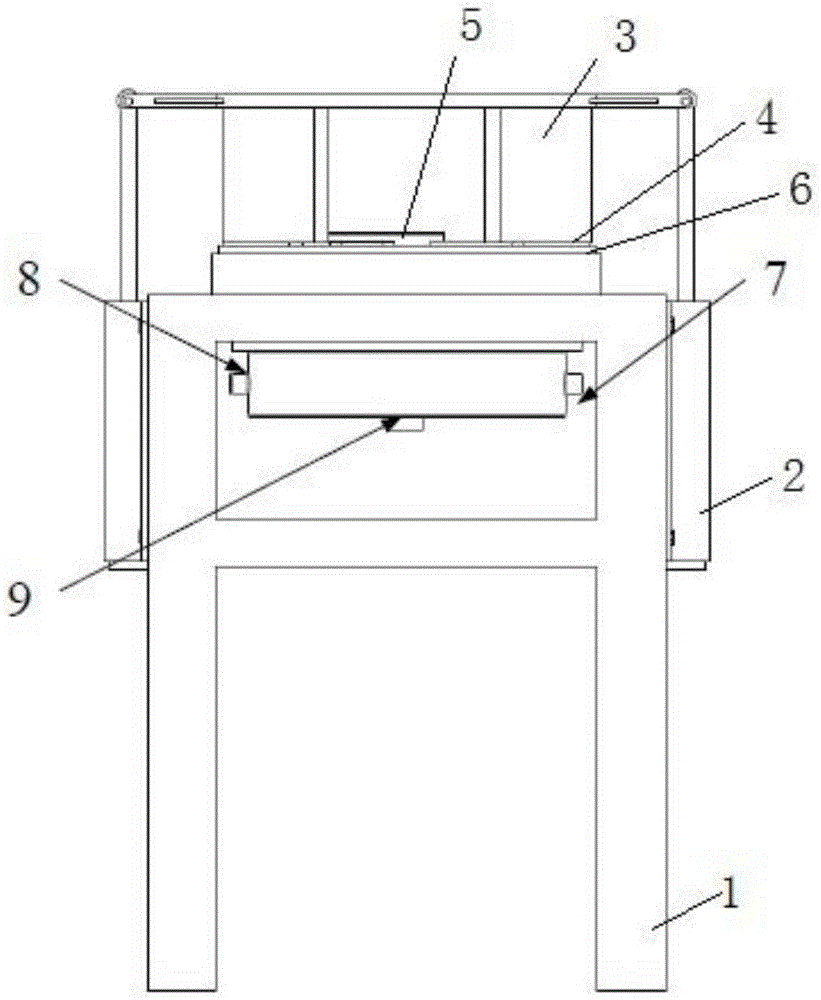

[0018] Such as Figures 1 to 3 As shown, a manhole cover positive and negative pressure performance test bench of the present invention includes a frame 1, a cylinder 2, a semi-circular symmetrical pressure plate 3, a manhole cover 5, a pressure sensor 9, and a three-position four-way electromagnetic switch. Directional valve 10, vacuum pump 11, two-position two-way electromagnetic reversing valve two 12, flow sensor 13, controller 14, test chamber 15, two-position two-way electromagnetic reversing valve one 16 and air source 17.

[0019] A test cavity 15 is set in the center of the frame 1, a manhole cover 5 is set on the upper part of the test cavity 15, a semi-circular symmetrical pressure plate 3 is set above the manhole cover 5, two cylinders 2 are symmetrically set on both sides of the frame 1, and the piston rod of the cylinder 2 Connected with the semi-circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com