Heating device for liquid heating

A technology for heating devices and liquids, applied in electric heating devices, fluid heaters, water heaters, etc., can solve the problems that the water temperature cannot be constant, the pressure cannot be stored, and the waiting time is long, and the waiting time for startup preheating can be reduced. , The effect of low manufacturing cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

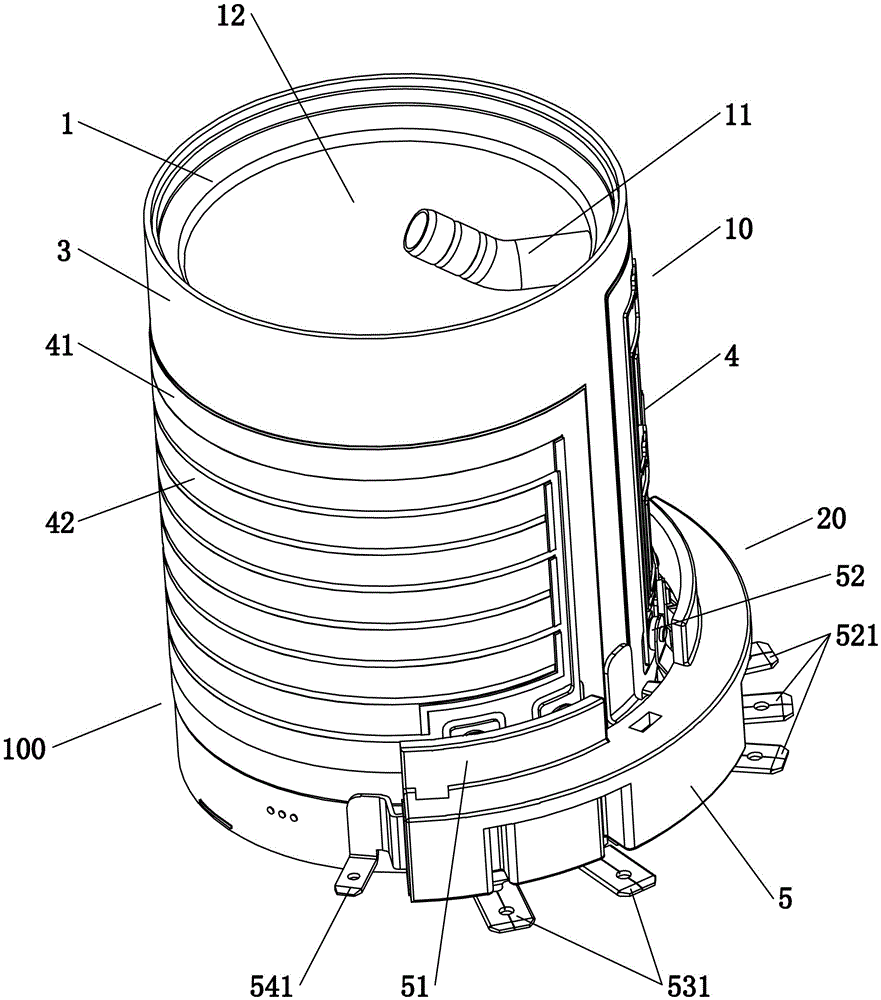

[0034] Embodiment one, see Figure 1 to Figure 5 As shown, a heating device 100 for liquid heating includes a sealing bracket 1, a heating body 10, a water inlet 14 and a water outlet 11, the sealing bracket 1 is sealed and connected to the heating body 10, and a cavity is enclosed between them The cavity is provided with a sealing body 2, and the sealing body 2 and the heating body 10 enclose a sealed waterway 8 with a certain capacity. The sealed waterway 8 communicates with the outside world through the water inlet 14 and the water outlet 11 respectively. The liquid is sealed and confined in the sealed water channel 8 , and finally flows out from the water outlet 11 along the sealed water channel 8 .

[0035] The sealing body 2 is provided with sealing ribs 21 corresponding to the straight communication path between the water inlet 14 and the water outlet 11 , and the sealing ribs 21 are sealingly matched with the heating body 10 . The sealing rib 21 is integrally formed w...

Embodiment 2

[0051] Embodiment two, the difference with embodiment one is: see Figure 6 As shown, the surface of the sealing bracket 1 is provided with a positioning portion 15 for defining the installation position of the sealing body. The positioning portion 15 is more than two convex points or ribs.

[0052] combine Figure 7 As shown, a water purification system with the above heating device 100 includes a filter assembly 9, a flow regulating device 30 and a heating device 100, the heating device 100 is provided with a water inlet 14 and a water outlet 11, the filter assembly 9, the flow regulating device 30 and the heating device 100 are connected in series through a waterway, and the filter assembly 9 is arranged on the waterway before the water inlet 14 .

[0053] It also includes an inlet water temperature detection device (inlet water temperature sensor 40), the filter assembly 9 includes a raw water area 91, a filter device 92 and a water purification area 93, and the raw wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com