Automatic control system and method for temperature of combustion section of vertical type annealing furnace

An automatic control system and vertical annealing furnace technology, applied in the direction of combustion method, controlled combustion, heat treatment process control, etc., can solve the problems of low temperature control accuracy, environmental pollution, and unsatisfactory temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

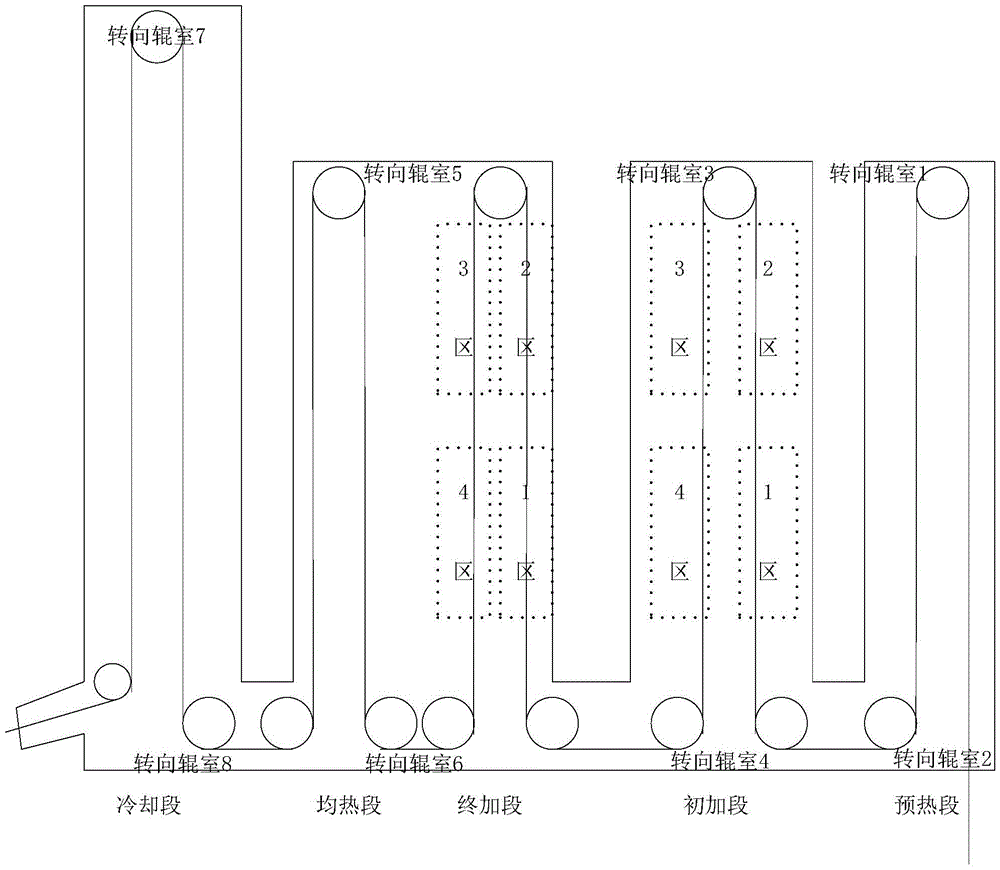

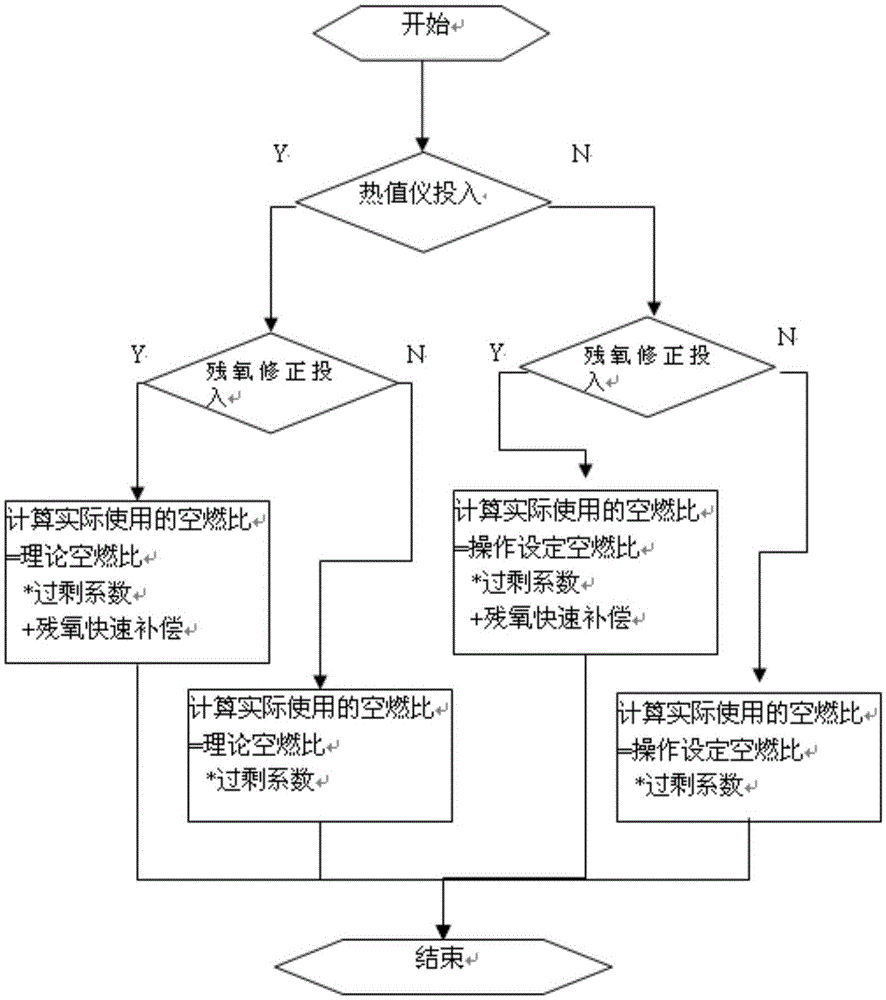

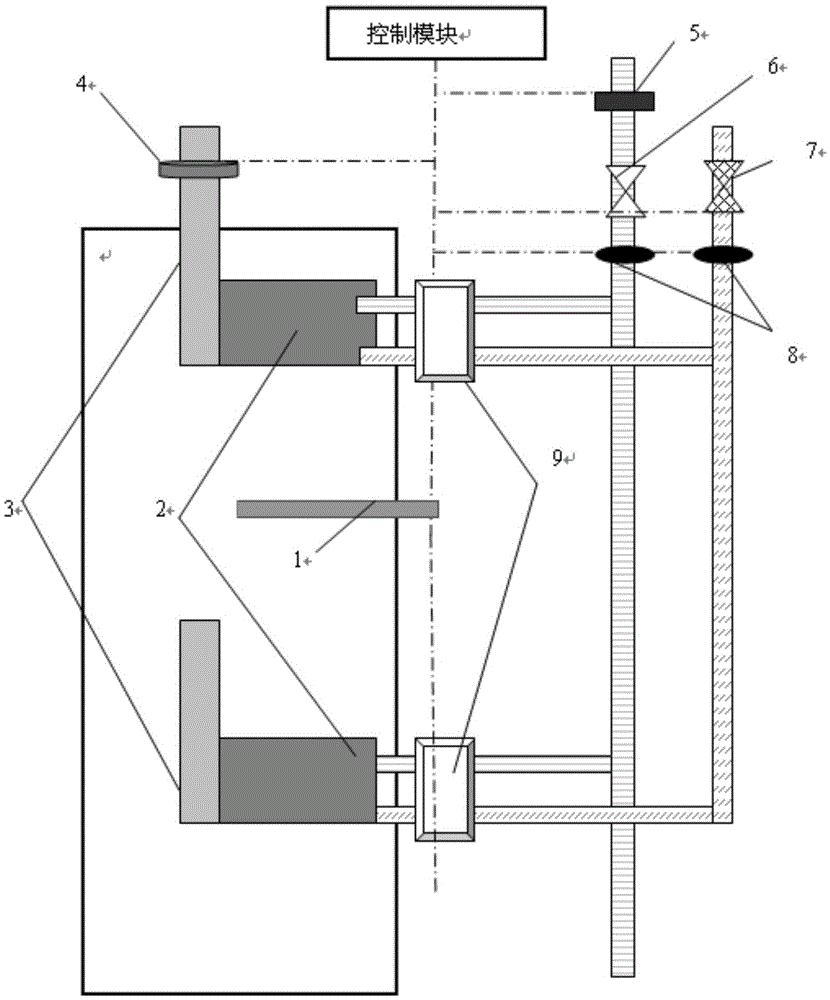

[0067] The automatic temperature control system of the combustion section of the vertical annealing furnace of the present invention will be described in detail below with specific examples. In one embodiment, the automatic temperature control system of the combustion section of the vertical annealing furnace includes: a control module, a temperature sensor 1, a radiant tube 2, a burner flue 3, a zirconia analyzer 4, a calorific value instrument 5, a natural gas regulator Valve 6, air regulating valve 7, flow sensor 8, combustion control unit 9. A natural gas regulating valve 6 and an air regulating valve 7 form a group, which are respectively connected with a flow sensor 8 . The combustion section of the annealing furnace includes an initial heating section, a final heating section, and a soaking section. The zirconia analyzer 4 is installed on a burner flue 3 in the initial heating section; the calorific value meter 4 is installed on the main natural gas pipeline, see the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com