Parabolic trough solar thermal power generation system and method utilizing fuse salt medium

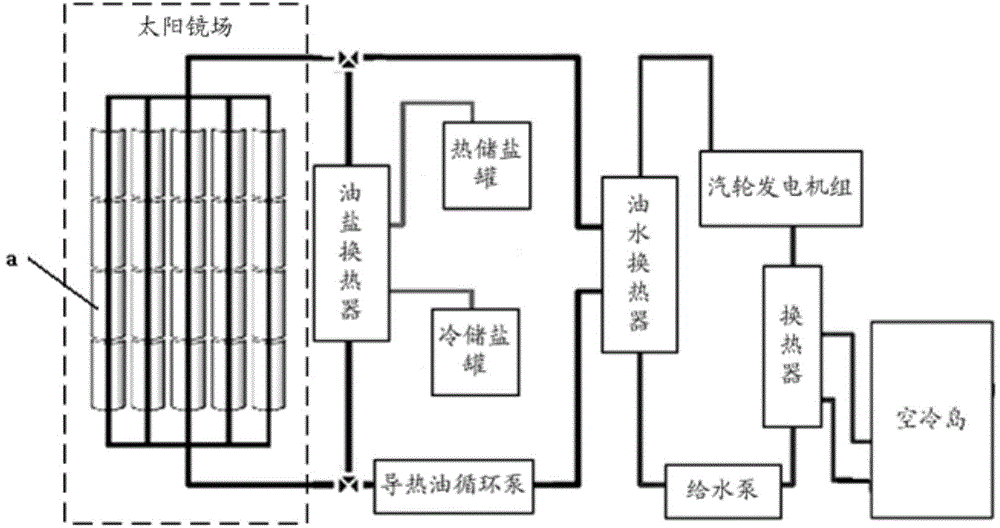

A trough solar and thermal power generation system technology, applied in the field of solar energy utilization, can solve problems such as difficulty in improving power generation efficiency, increasing system cost, and easy solidification of molten salt, reducing configuration complexity, reducing system cost, and improving safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

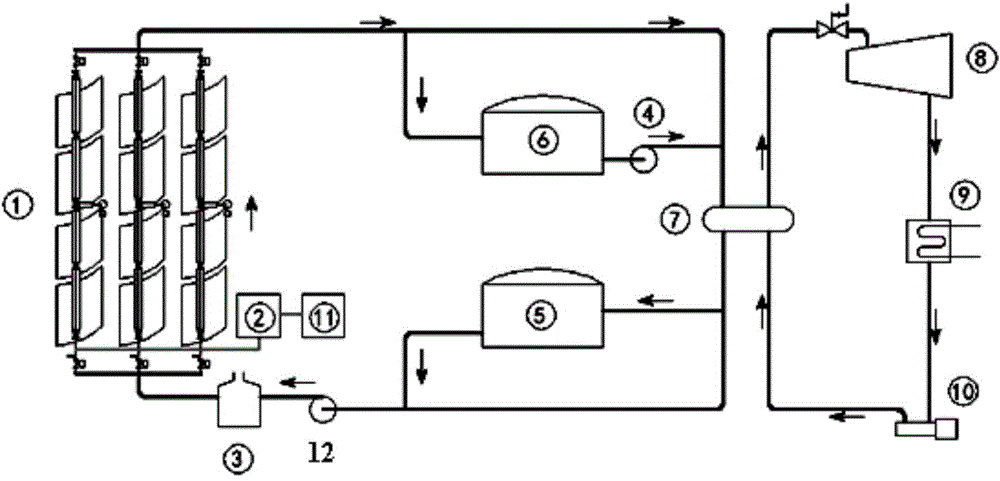

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

[0038] Such as figure 1 As shown, the present invention provides a trough solar thermal power generation system using a molten salt medium, including a trough collector 1, a brine heat exchanger 7, a turbo generator 8, a low-temperature heat storage tank 5, and a high-temperature heat storage tank 6 and exhaust molten salt system;

[0039] The salt outlet of the trough collector 1 is divided into two branches, one branch is directly connected to the salt inlet of the brine heat exchanger 7, and the other branch is connected to the salt inlet of the high-temperature heat storage tank 6; The salt outlet of the heat storage tank 6 is connected to the salt inlet of the brine heat exchanger 7 through the first molten salt pump 4; The exhaust port of 7 is connected to the air inlet of turbo-generator 8, the exhaust port of steam-turbine generator 8 is connected to the air inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com