Casing type water-cooling cooler of automobile engine

A car engine, water-cooled cooling technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of many pollutants and high fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A special tool for engine valve disassembly and assembly of the present invention will be further described in detail below in conjunction with the accompanying drawings;

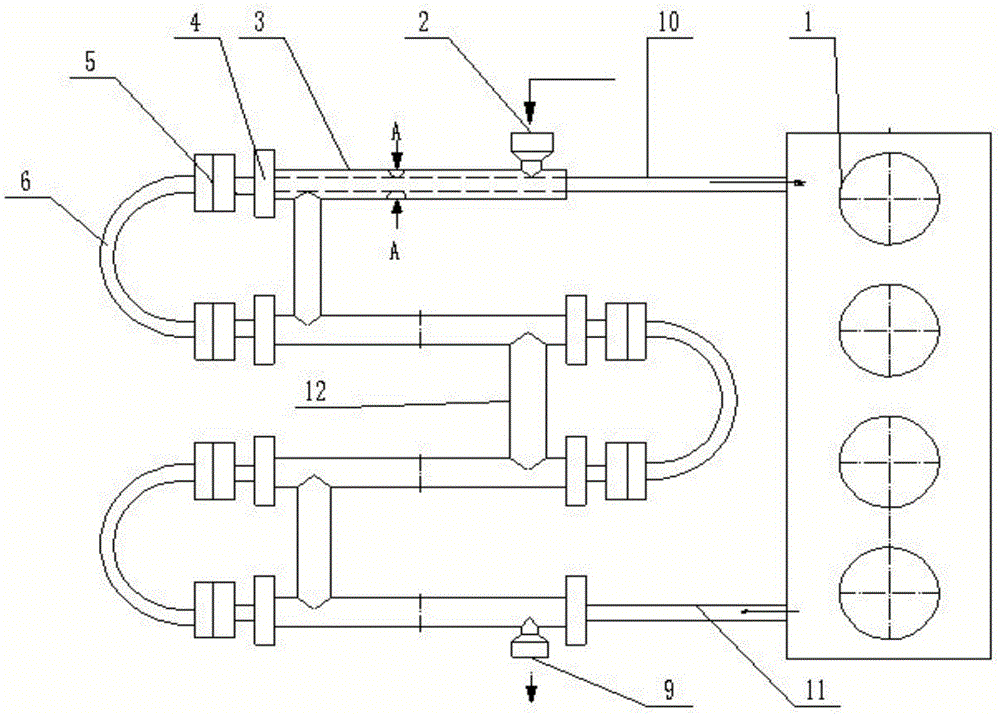

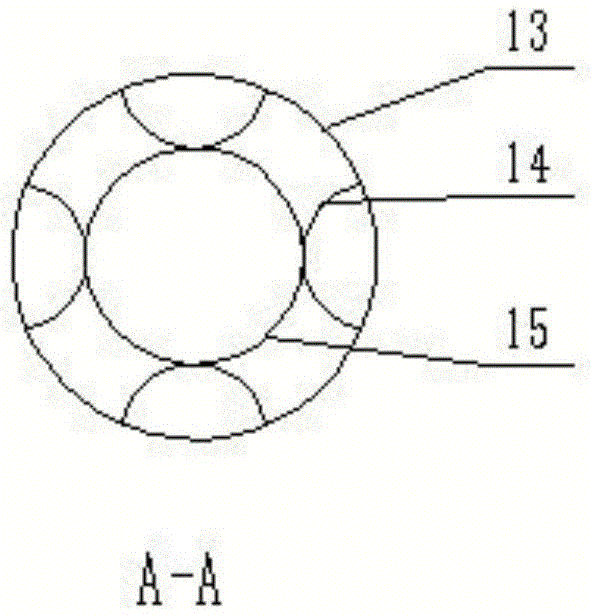

[0009] Depend on figure 1 Visible, this implementation is a kind of automobile engine casing type water-cooled cooler of the present invention: mainly by engine water jacket (1), air casing inlet (2), air casing (3,13), air casing sealing end ( 4), water pipe joint (5), water pipe elbow (6), air sleeve outlet (9), water pipe outlet (10), water pipe inlet (11), air sleeve transition pipe (12), air sleeve inner bracket ( 14), water pipe (15) constitutes.

[0010] Depend on figure 1 It can be seen that the casing-type water-cooled cooler for an automobile engine is characterized in that: the flow direction of the compressed air loaded on the periphery of the water pipe is just opposite to the flow direction of the water in the water pipe, which is beneficial to the loss of engine heat.

[0011] Depen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com