Method for realizing variable filtrational resistance oil displacement

A technology for seepage resistance and oil displacement, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

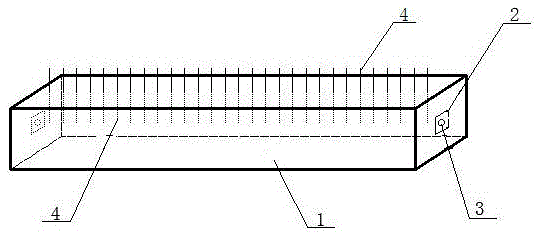

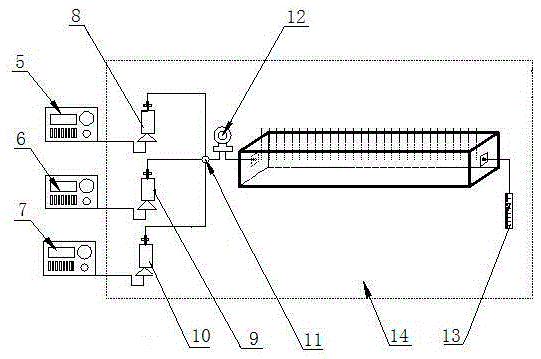

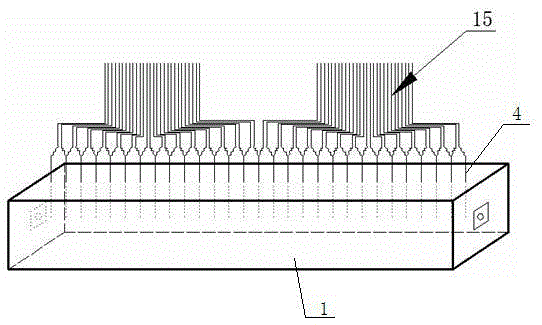

[0083] The present invention will be further explained below in conjunction with the drawings:

[0084] The method to achieve variable seepage resistance flooding is as follows:

[0085] 1. The core used is the actual three-layer heterogeneous natural core of an oil field, and the reservoir structure parameters of different permeability layers are tested; the scanning machine used in this section is the image processing and analysis system of the GELightSpeedPlusCT machine, which is scanned by the core It consists of gantry, detector, X-ray source, data acquisition and image processing. The main frequency of the computer of the scanning system is 2*3.2GHz, the memory is 2GB, and it provides DICOM3.0 standard interface, high-speed network transmission data, and the transmission data is 10 frames / s, the computer uses Linux operating system.

[0086] (1) According to the heterogeneity of the actual natural core, the permeability of each layer of the actual reservoir is determined to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com