A single-pipe double-layer injection process string for carbon dioxide flooding

A carbon dioxide and process pipe string technology, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of difficult construction, high construction cost, and affecting production, so as to avoid maintenance operations and switching Convenience and the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

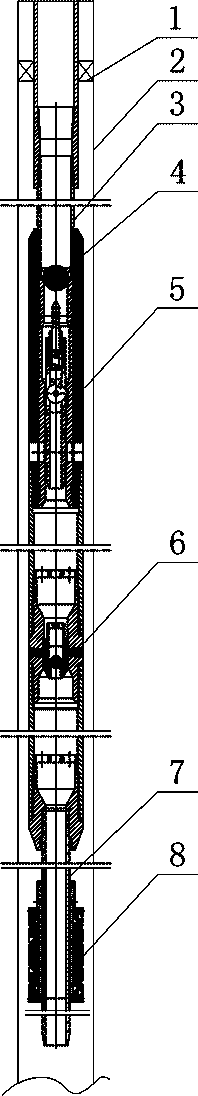

[0014] Such as figure 1 As shown, the string of the single-pipe double-layer injection process for carbon dioxide flooding oil flooding of the present invention includes a casing 2, an oil pipe 3 is arranged in the casing, and a drillable bridge plug 8 is arranged in the casing, and the bridge plug can be drilled to close the casing. It is divided into an upper section and a lower section. A sealing cannula 7 is inserted on the drillable bridge plug. The sealing cannula is preferably a self-supporting formal sealing cannula. There are a setting ball valve 6, a throwing and fishing distribution device 5 and a packer 1.

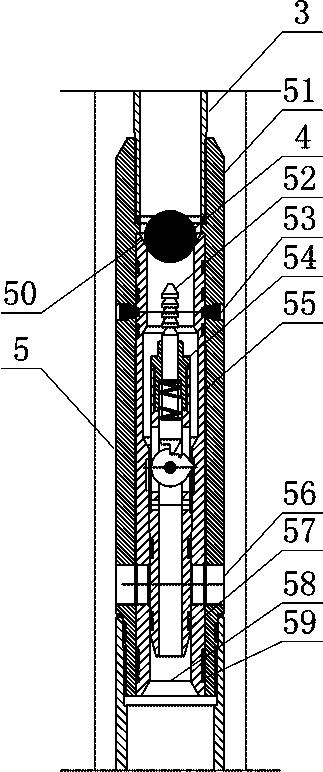

[0015] Such as figure 2 As shown, the fishing-type distribution device includes an outer cylinder 51 connected to oil pipes at both ends, and an inner sliding cylinder 55 that is slidingly and sealingly matched with the inner wall of the outer cylinder is arranged in the outer cylinder, and an inner sliding cylinder is provided on the outer cylinder to preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com