Small viscous damper

A viscous damper and damping technology, which is applied in the direction of building components, building structures, and earthquake resistance, can solve the problems of large installation space, damping force cannot be adjusted, and limit the energy consumption capacity of the damper, so as to ensure the damping force and prevent exposed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

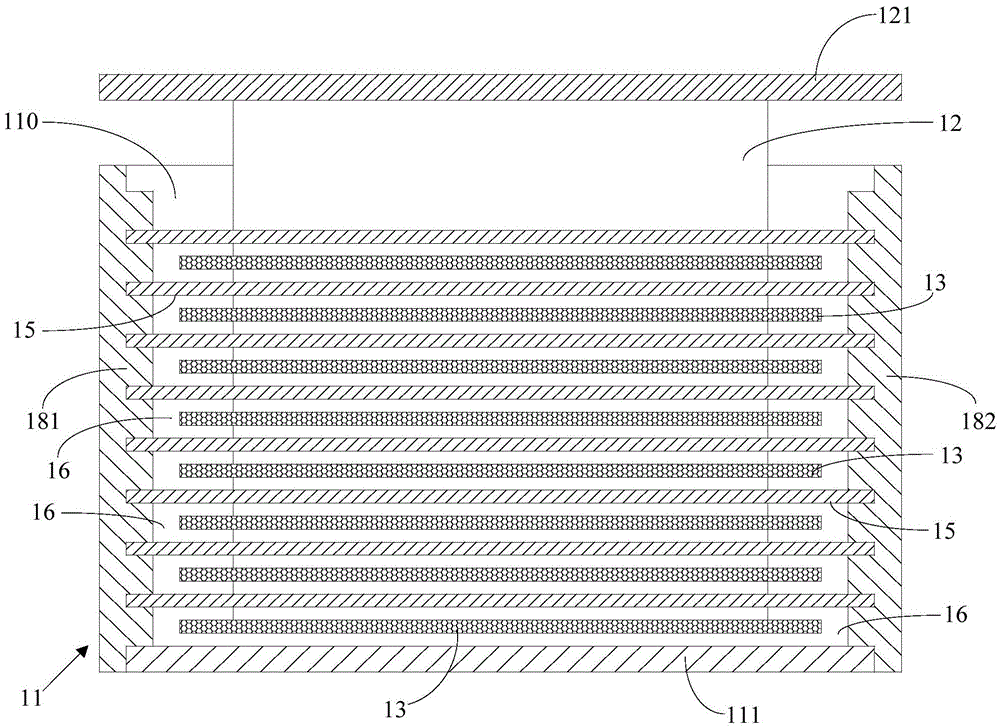

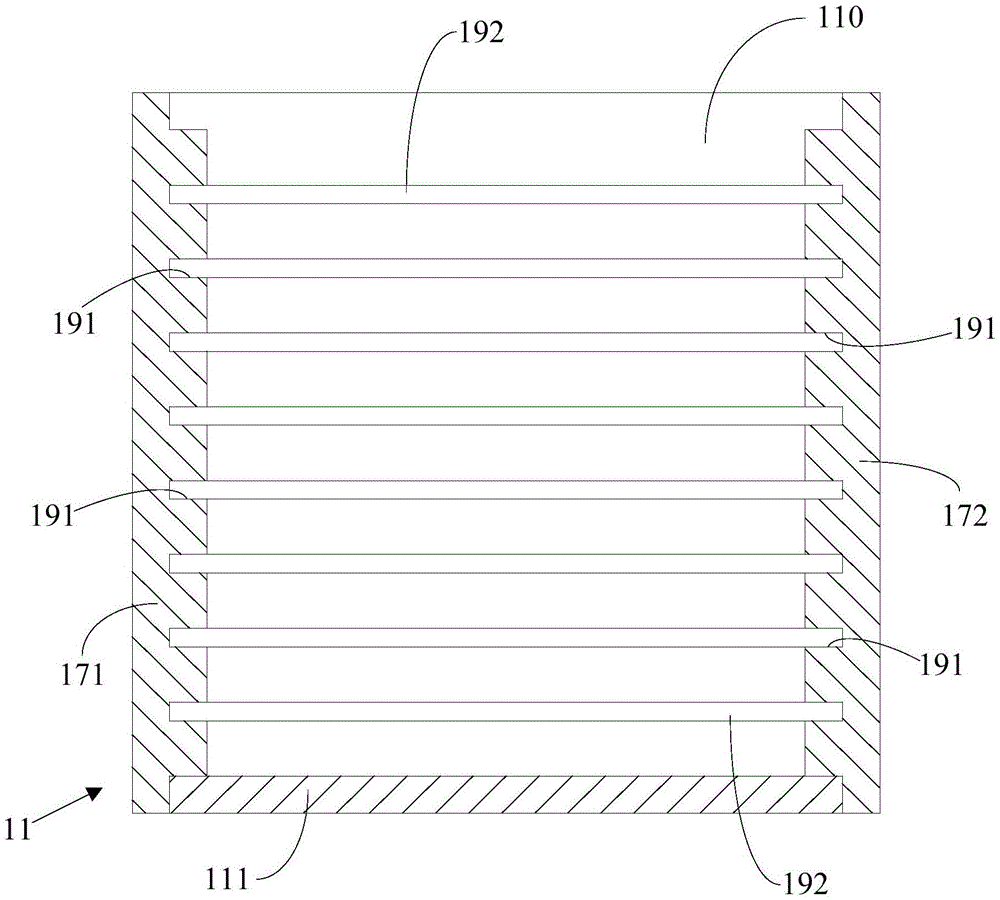

[0023] see first figure 1 and figure 2 As shown, a small viscous damper of the present invention is mainly composed of a damping box 11 , a connecting plate 12 , a plurality of shear plates 13 and damping fillers 14 .

[0024] The top of the damping box 11 is provided with an opening 110, and the bottom of the damping box 11 is provided with a connecting bottom plate 111. The connecting bottom plate 111 can be rigidly connected with the underlying building structure during use, or fixed on the underlying building structure through a bracket. A plurality of adjustable baffles 15 are inserted on both sides of the inside of the damping box 11, so that a plurality of shearing areas 16 arranged up and down are formed on both sides of the inside of the damping box 11, and the damping filler 14 is arranged in a plurality of shearing areas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com