Suspension type coal bunker damping structure improving heat-engine plant main workshop antivibration performance

A seismic performance, suspension technology, applied in seismic, building components, industrial buildings and other directions, can solve the problems of large horizontal seismic action, high action position, unsatisfactory seismic performance, etc., to reduce displacement amplitude, prevent collision, improve The effect of additional damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

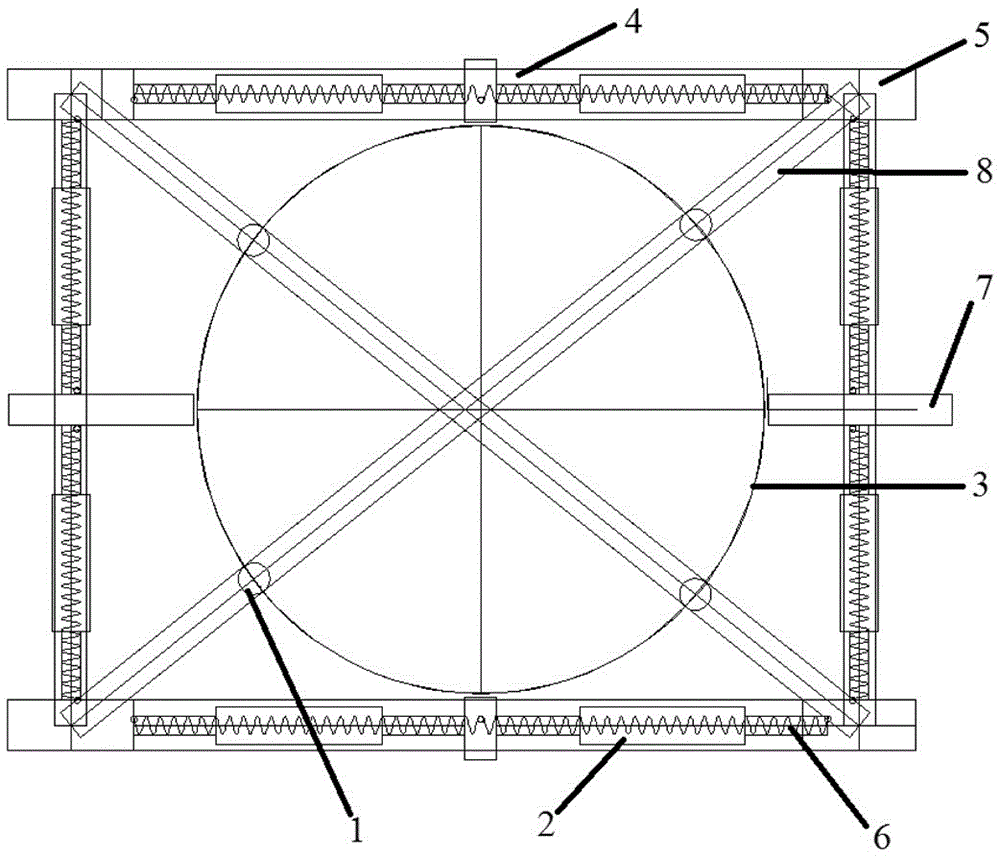

[0019] Such as Figure 1 to Figure 3 As shown, the present invention proposes a suspension type coal hopper shock-absorbing structure for improving the seismic performance of the main building of a thermal power plant, including 4 frame columns 5, 8 frame beams 4, 2 coal hopper beams 8, 4 hanging Rod 1, 8 springs 6, 8 dampers 2, 1 steel coal bucket 3, 4 connectors 7.

[0020] Four frame columns 5 and eight frame beams 4 form a frame system, and the frame beams 4 are arranged on the frame columns 5 .

[0021] The steel coal hopper 3 includes a cylindrical coal hopper upper part 31 and a conical coal hopper lower part 32 .

[0022] In the horizontal direction, two coal bucket beams 8 are horizontally and obliquely intersected on the frame column 5 .

[0023] One end of the four suspenders 1 is connected to the steel coal scuttle 3 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com