Steel pipe grouting pile

A technology of grouting piles and steel pipe piles, which is applied in the field of steel pipe grouting piles, can solve problems such as poor foundation, abnormal engineering, and inability to construct large-scale construction equipment, so as to improve bearing capacity, prevent overall instability, and improve resistance The effect of compression and pull-out capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

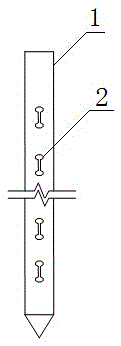

[0015] Embodiment 1: as figure 1 and figure 2 As shown, a steel pipe grouting pile includes a steel pipe pile body 1 , the bottom of which is tapered, and several through holes 2 are evenly arranged on the side wall of the steel pipe pile body 1 .

[0016] The diameter of the steel pipe pile body 1 is 50-150mm.

[0017] The steel pipe pile body 1 is a thin-walled steel pipe pile.

[0018] The through hole 2 is a candied fruit-shaped through hole.

Embodiment 2

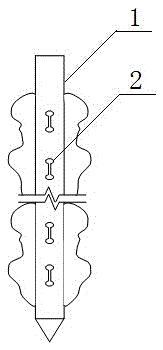

[0019] Embodiment 2: A steel pipe grouting pile, comprising a steel pipe pile body 1 , the bottom of the steel pipe pile body 1 is conical, and several through holes 2 are uniformly arranged on the side wall of the steel pipe pile body 1 .

[0020] The diameter of the steel pipe pile body 1 is 50-150mm.

[0021] The steel pipe pile body 1 is a thin-walled steel pipe pile.

[0022] The through hole 2 is a Z-shaped through hole.

Embodiment 3

[0023] Embodiment 3: A steel pipe grouting pile, comprising a steel pipe pile body 1 , the bottom of the steel pipe pile body 1 is conical, and several through holes 2 are uniformly arranged on the side wall of the steel pipe pile body 1 .

[0024] The diameter of the steel pipe pile body 1 is 50-150mm.

[0025] The steel pipe pile body 1 is a thin-walled steel pipe pile.

[0026] The through hole 2 is an S-shaped through hole.

[0027] To sum up, the steel pipe grouting pile of the present invention opens holes on the side wall of the thin-walled steel pipe pile, and then uses pressure grouting equipment to inject chemical grout into the soil around the steel pipe pile through the openings in the side wall; the grout itself It has good strength, and can also be mixed with the soil around the pile body, and undergo physical and chemical reactions to form a reinforced soil with high strength; the grout and reinforced soil form a large hard block around the grouting hole body,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com