Large rolling broom and small rolling broom combined cleaning mechanism for motor sweeper

A cleaning mechanism and cleaning vehicle technology, applied in road cleaning, cleaning methods, construction and other directions, can solve the problems of large obstacles, high requirements for cleaning environment, etc., and achieve simple structure, low use cost, and easy transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

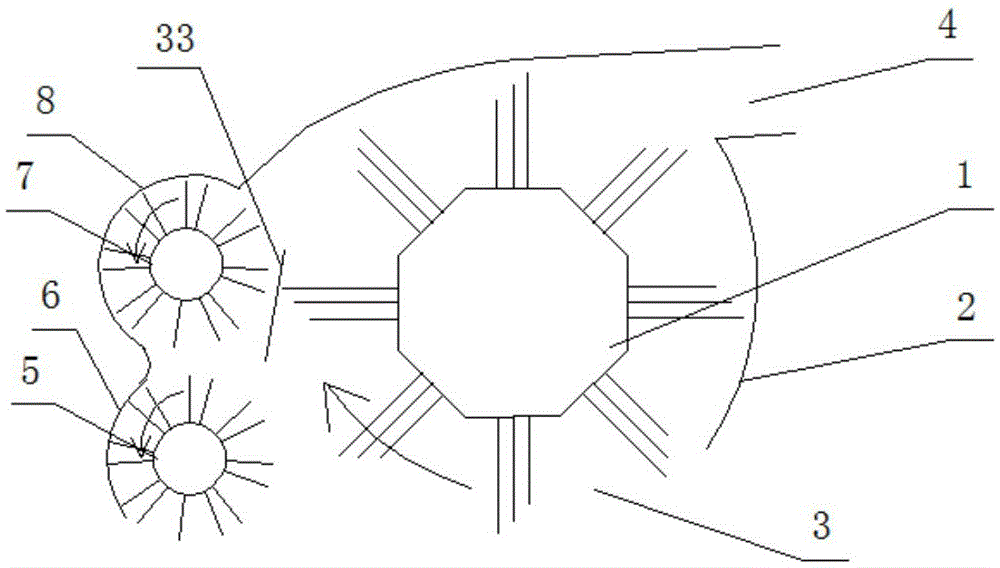

[0035] Such as figure 1 Shown, a kind of sweeping vehicle big and small roll-sweep combination cleaning mechanism described in the present invention comprises big roll-sweeping 1, big rolling-sweeping cover 2, small rolling-sweeping 5 and small rolling-sweeping cover 6, big rolling-sweeping cover 2 and small rolling-sweeping cover 2 The axial ends of the sweeping cover 6 are provided with closed end plates, and the rotating shafts of the large rolling sweep 1 and the small rolling sweep 5 are installed on the two end plates, and it is characterized in that the large rolling sweeping cover 2 and the small rolling sweeping cover 6 are in phase. connected, and the adjacent parts of the large roller sweep 1 and the small roller sweep 5 are exposed (that is, the adjacent parts of the large roller sweep 1 and the small roller sweep 5 are open to each other, that is, there is no obstruction between them, The absence of any cover means that there is no rolling sweep cover or garbage g...

example 2

[0037] Such as Picture 1-1 As shown, a large and small rolling sweeping combination cleaning mechanism of a cleaning vehicle according to the present invention includes a large rolling sweep 1, a large rolling sweeping cover 2, a small rolling sweep 5, a small rolling sweeping cover 6, and a small rolling sweeping dust-proof roller brush 7 , the small rolling sweeping dust-retaining roller brush cover 8 and the garbage channel 9, the axial ends of the large rolling sweeping outer cover 2, the small rolling sweeping outer cover 6 and the small rolling sweeping dust-retaining roller brush 7 are provided with closed end plates, and the large The rotating shafts of rolling sweep 1, small rolling sweep 5 and small rolling sweeping dust retaining roller brush 7 are installed on the two end plates. It is characterized in that the upper position of the small rolling sweep 5 is provided with a small rolling sweep dust retaining roller brush 7 and a small rolling sweep dust retaining r...

example 3

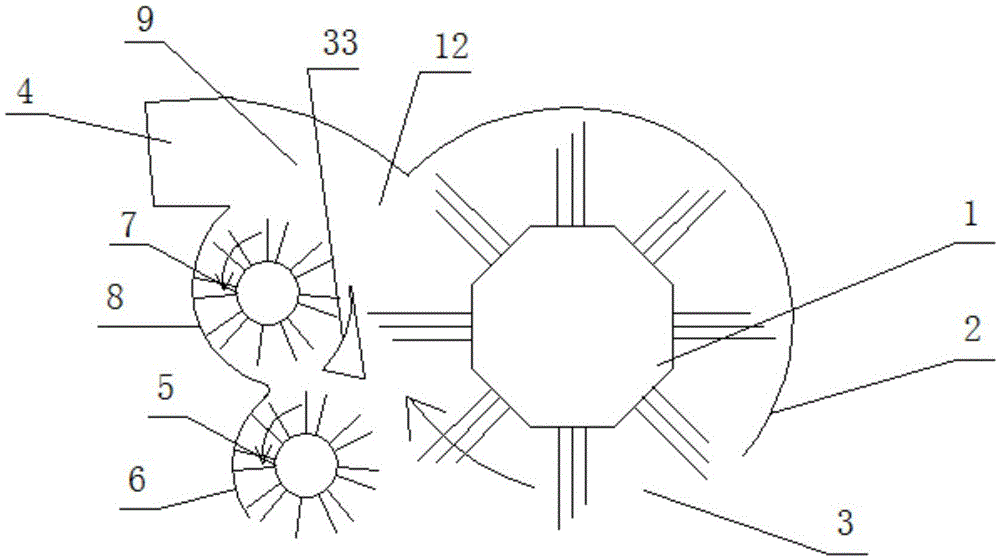

[0039] Such as Figure 1-2 As shown, a large and small rolling sweeping combination cleaning mechanism of a cleaning vehicle according to the present invention includes a large rolling sweep 1, a large rolling sweeping cover 2, a small rolling sweep 5, a small rolling sweeping cover 6, and a small rolling sweeping dust-proof roller brush 7 and the dust-retaining roller brush cover 8, the axial ends of the large roller-sweep outer cover 2, the small roller-sweep outer cover 6 and the small roller-sweep dust-proof roller brush 7 are all provided with closed end plates, and the large roller sweep 1 and the small roller sweep 5 and the rotating shaft of little rolling sweep dust retaining roller brush 7 are installed on the two end plates. It is characterized in that there is a garbage port 12 at the middle or upper middle part of the large rolling sweep cover 2 adjacent to the large rolling sweep 1 and the small rolling sweep 5, and a small rolling sweep stop is provided at the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com