Carbonizing treatment equipment for multiple waste materials of ship and treatment process adopting carbonizing treatment equipment

A technology of processing equipment and processing technology, which is applied in the direction of petroleum industry, special dry distillation, coke oven, etc., can solve the problems of no unified processing equipment for various garbage, single processed materials, and low degree of automation, etc., and achieve compact structure and automation The effect of high degree and strong equipment automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

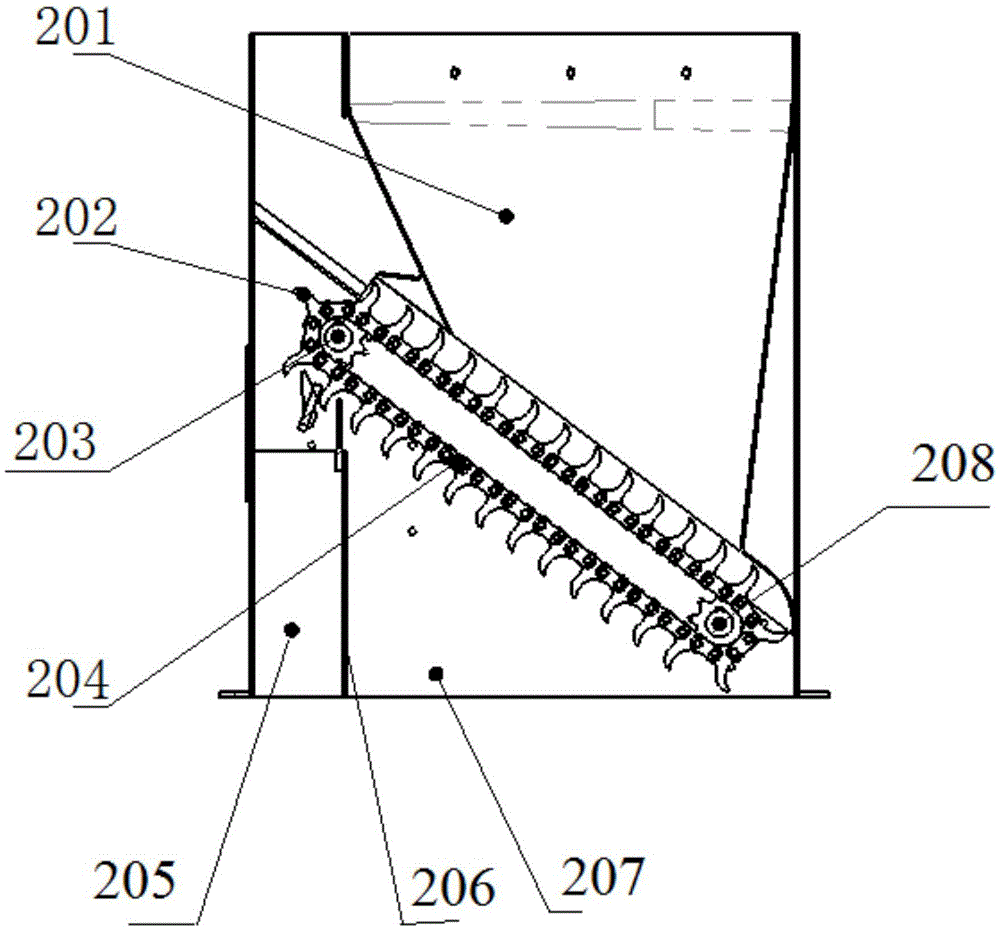

[0045] Embodiment 1. A variety of marine garbage carbonization treatment equipment

[0046] Such as figure 1 and image 3 As shown, the marine garbage carbonization treatment equipment of this embodiment includes a feeding mechanism 1, a filtering mechanism 2, a solid crushing mechanism 3, a vacuum system 4, an upper valve 8, a storage hopper 5, a lower valve 6, a carbonization furnace 7, Discharging mechanism 9, vacuum cleaner 10, storage tank. Above parts all erect on the iron frame 11. The feeding mechanism 1 is connected with the filtering mechanism 2 . Both the filter mechanism 2 and the solid crushing mechanism 3 are connected with the upper valve 8, and the upper valve 8, the storage hopper 5, the lower valve 6 and the carbonization furnace 7 are connected sequentially from top to bottom. The carbonization furnace 7 is connected with the vacuum system 4 , the carbonization furnace 7 is also connected with the discharge mechanism 9 , and the discharge mechanism 9 is ...

Embodiment 2

[0072] Embodiment 2, the treatment process of various marine garbage carbonization treatment equipment

[0073] Such as Figure 7 As shown, the food waste on the ship is transported to the filter mechanism through the feeding mechanism for solid-liquid filtration, the separated liquid enters the liquid receiving container, and the solid enters the storage hopper through the upper valve (at this time, the upper valve is opened and the lower valve is closed). After the medical solid waste and other solid waste on board are crushed by the solid crushing mechanism, they enter the storage hopper through the upper valve (at this time, the upper valve is opened and the lower valve is closed).

[0074] Close the upper valve and open the lower valve so that the material in the storage hopper enters the carbonization furnace for vacuum dehydration and carbonization. Vacuum dehydration is: heating at -0.09MP environment, vacuum dehydration is realized at 50 to 70°C, and the steam is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com