Cis-tetrahydrocarboline intermediate and synthesis method thereof, and application of cis-tetrahydrocarboline intermediate in preparing tadalafil

A technology of tetrahydrocarboline and synthesis method, which is applied in the field of cis-tetrahydrocarboline intermediate and its synthesis, and the preparation of tadalafil, can solve the problems of inconvenient purchase and use, and achieve loss avoidance, high yield, and improved The effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

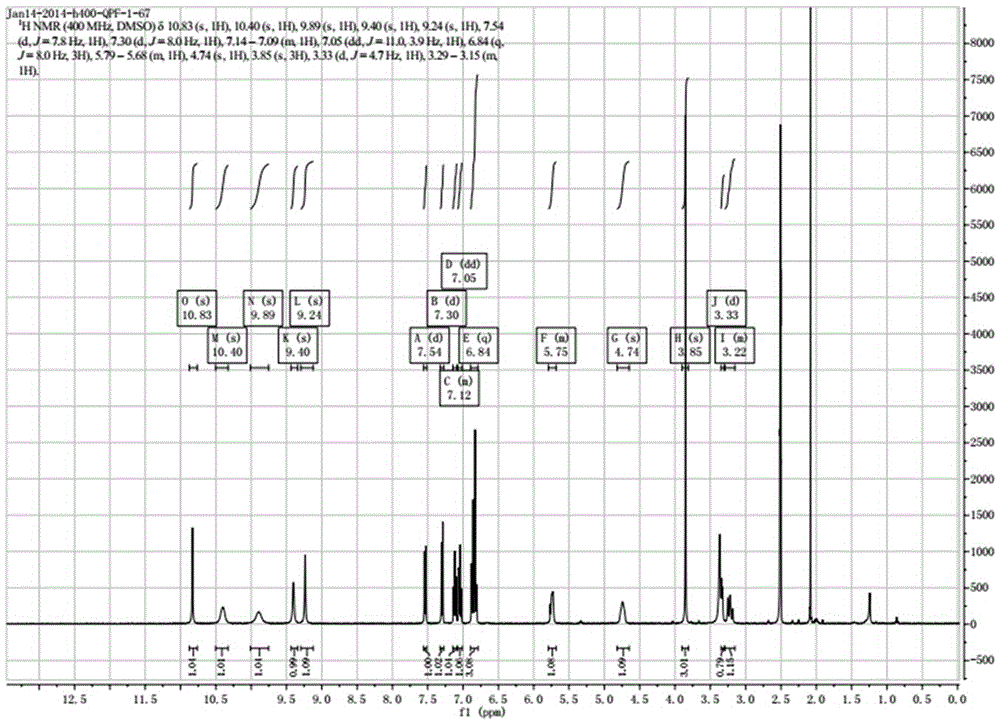

Image

Examples

Embodiment 1

[0037] Add 25.5 grams of D-tryptophan methyl ester hydrochloride to the reaction flask, add 150 milliliters of isopropanol at room temperature, stir, add 1.2 equivalents of 3,4-dihydroxybenzaldehyde, and react at 85°C for 8 hours until the raw material The reaction was basically complete, cooled to room temperature, filtered, and the solid was washed with 50 ml of isopropanol, and then dried in an oven to constant weight. 34.6 g of compound I were obtained in a yield of 92%. The synthetic route map is attached figure 1 shown.

Embodiment 2

[0039] Add 25.5 grams of D-tryptophan methyl ester hydrochloride to the reaction flask, add 250 milliliters of propionitrile at room temperature, stir, add 1.5 equivalents of 3,4-dihydroxybenzaldehyde, and react at 85°C for 16 hours until the raw materials are basically After the reaction was complete, it was cooled to room temperature, filtered, and the solid was washed with 50 ml of isopropanol, and then dried in an oven to constant weight. 34.2 g of Compound I were obtained in a yield of 97%. The synthetic route map is attached figure 1 shown.

Embodiment 3

[0041] Add 25.5 grams of D-tryptophan methyl ester hydrochloride to the reaction flask, add 375 milliliters of methanol at room temperature, stir, add 1.5 equivalents of 3,4-dihydroxybenzaldehyde, and react at 60°C for 24 hours until the raw materials basically react completely, cooled to room temperature, filtered, the solid was washed with 50 ml of methanol, and then dried in an oven to constant weight. 33.8 g of compound I were obtained in a yield of 90%. The synthetic route map is attached figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com