Digital and intelligent integrated production line for electronic and electrical appliances and production process for digital and intelligent integrated production line

A technology for electronic appliances and production lines, applied in the direction of conveyor objects, conveyors, mechanical conveyors, etc., can solve problems such as incompleteness, achieve accurate data information, reduce production costs, and finely control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

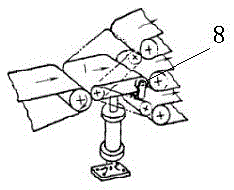

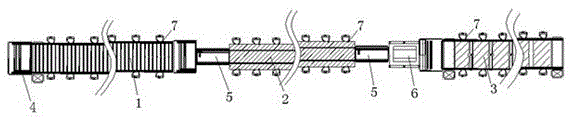

[0023] An integrated production line of digital intelligent electronic appliances, the integrated production line mainly includes basic equipment, a control system 4, a signal and a detection system, wherein the basic equipment is composed of an assembly line 1, an inspection line 2 and a packaging line 3; the control System 4 monitors the basic equipment and the working conditions of the signal detection system through PLC single-chip microcomputer technology.

[0024] The assembly line 1 mainly includes a workbench and an assembly conveying line. The workbench is installed above the assembly conveying line. The workbench is an assembly tooling plate 7 arranged at intervals on both sides above the conveyor belt. Each tooling plate 7 is equipped with The fixture with RFID card function is implanted; the assembly conveying line adopts a single-layer belt conveying method, and the end of the conveying belt is connected to the inspection line 2 through a parallel transfer mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com