Frequency converting control system and control method suitable for central cooling system of ship

A cooling system, frequency conversion control technology, applied in hull ventilation/heating/cooling, ship components, ship construction, etc., can solve the problems of wasting electric energy, limited energy saving effect, excess cooling capacity of seawater pumps, etc., and achieve simple and convenient operation and energy saving Obvious effect and remarkable energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

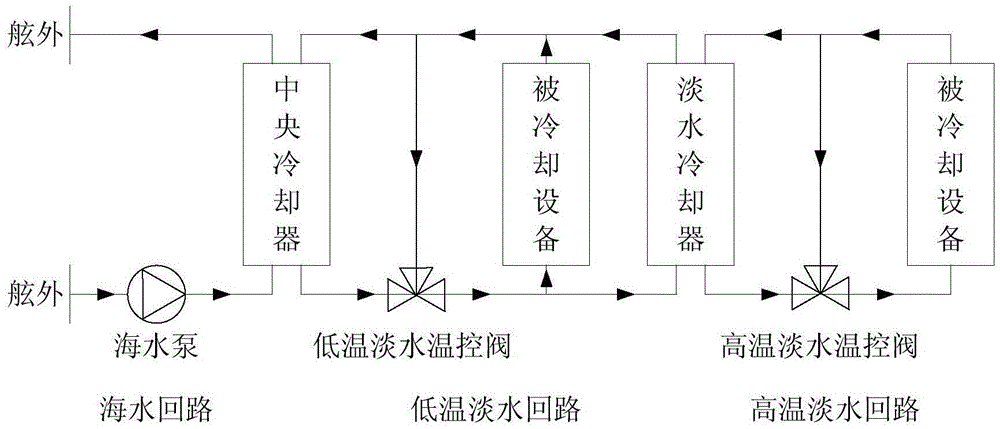

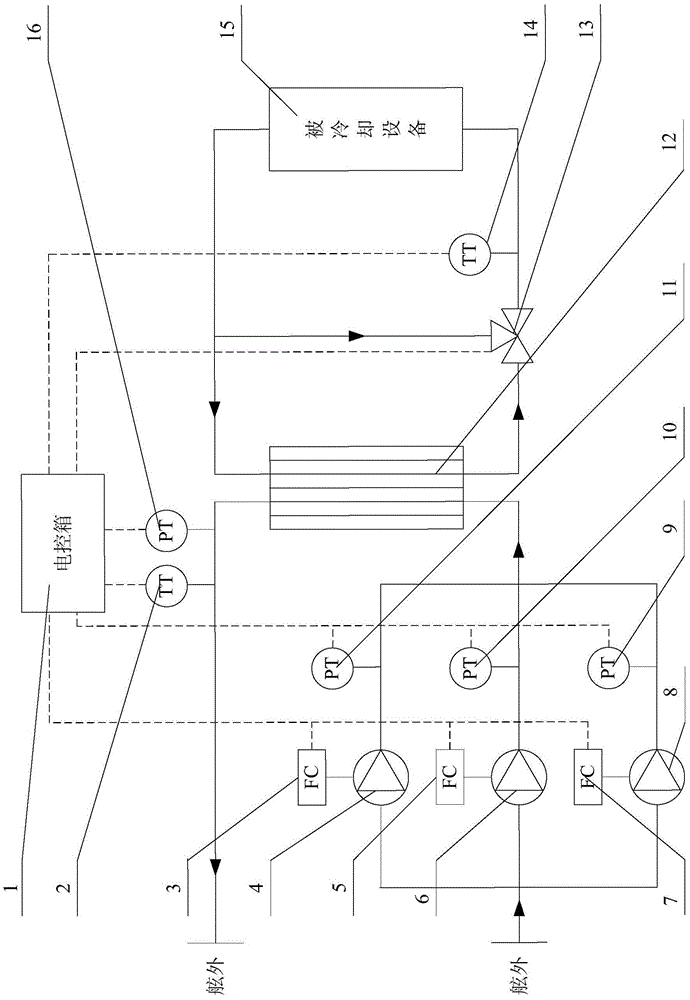

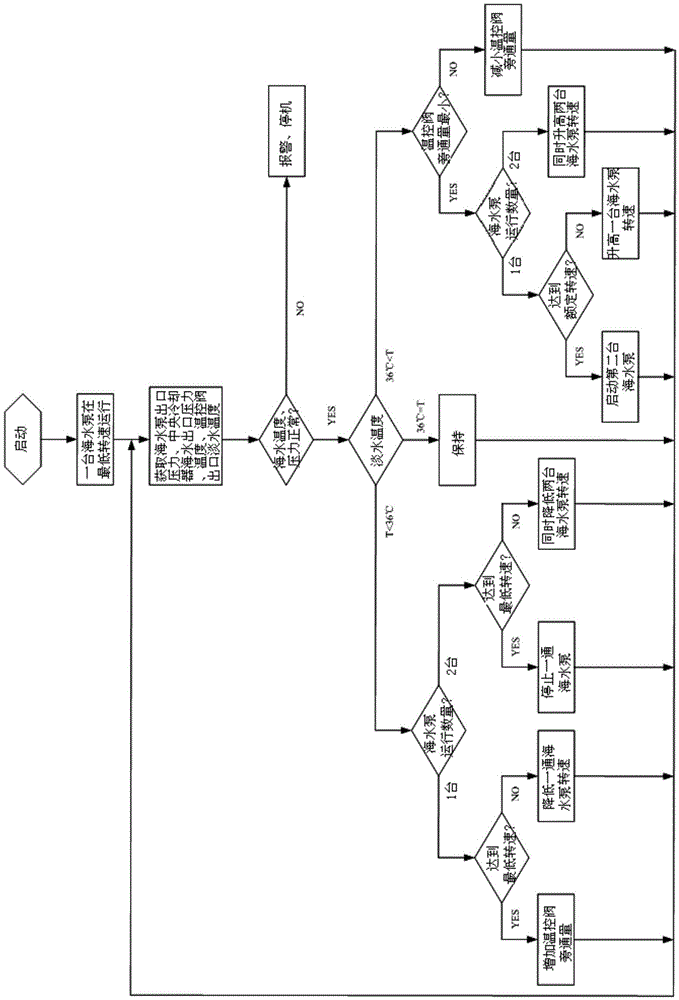

[0020] Such as figure 2 The structure diagram of the frequency conversion control system suitable for the ship's central cooling system is shown. The system is mainly composed of the electric control box 1, the sea water temperature sensor 2, the No. 1 inverter 3, the No. 1 sea water pump 4, the No. 2 inverter 5, and the No. 2 sea water pump 6, No. 3 inverter 7, No. 3 sea water pump 8, No. 3 pressure sensor 9, No. 2 pressure sensor 10, No. 1 pressure sensor 11, central cooler 12, temperature control valve 13, fresh water temperature sensor 14, cooled equipment 15. Seawater pressure sensor 16 and other equipment constitute.

[0021] No. 1 sea water pump 4, No. 2 sea water pump 6, and No. 3 sea water pump 8 are connected in parallel, and are respectively driven by No. 1 inverter 3, No. 2 inverter 5, and No. 3 inverter 7. Sent to central cooler 12, seawater directly discharges outboard after absorbing the heat of fresh water in central cooler 12.

[0022] The fresh water coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com