A long fiber bundle melt impregnation system

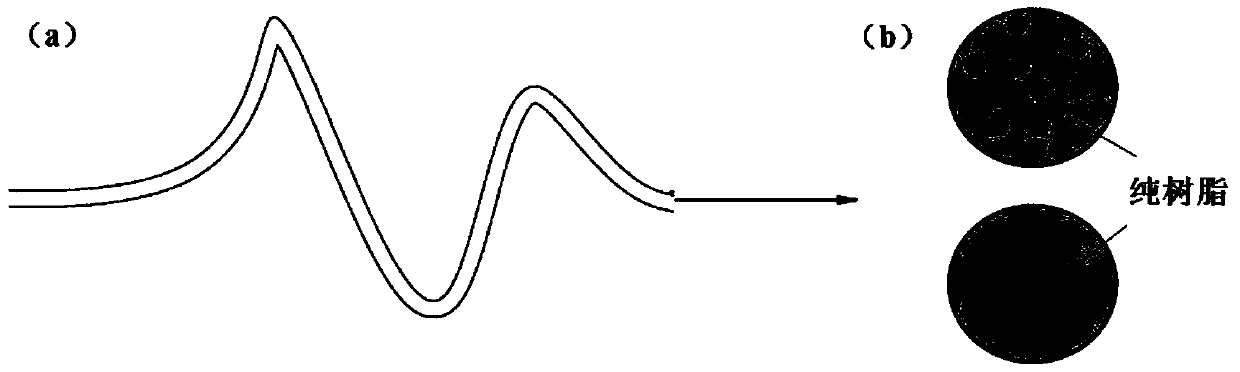

A technology of melt impregnation and long fibers, applied in the direction of coating, etc., can solve the problems of insufficient infiltration, poor dispersion uniformity, large fiber breakage, etc., and achieve the effect of improving the impregnation effect, sufficient infiltration, and less fiber breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

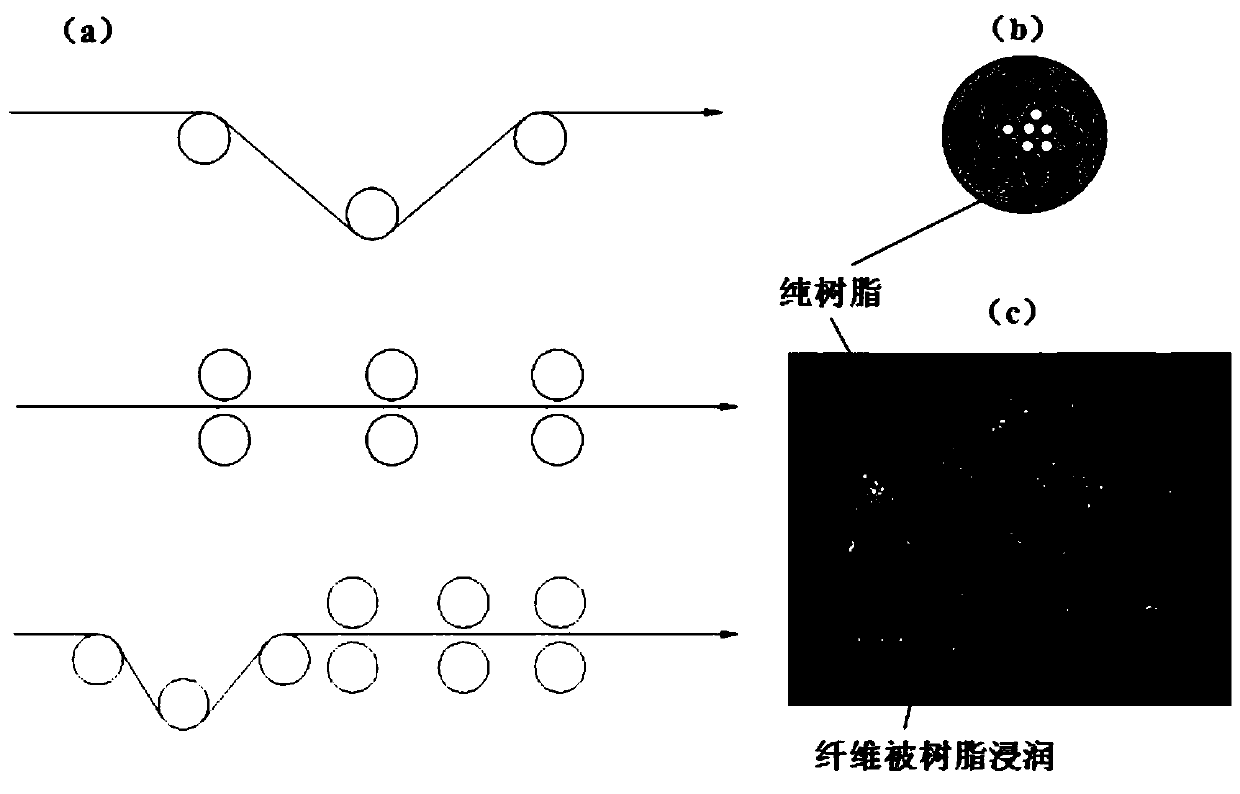

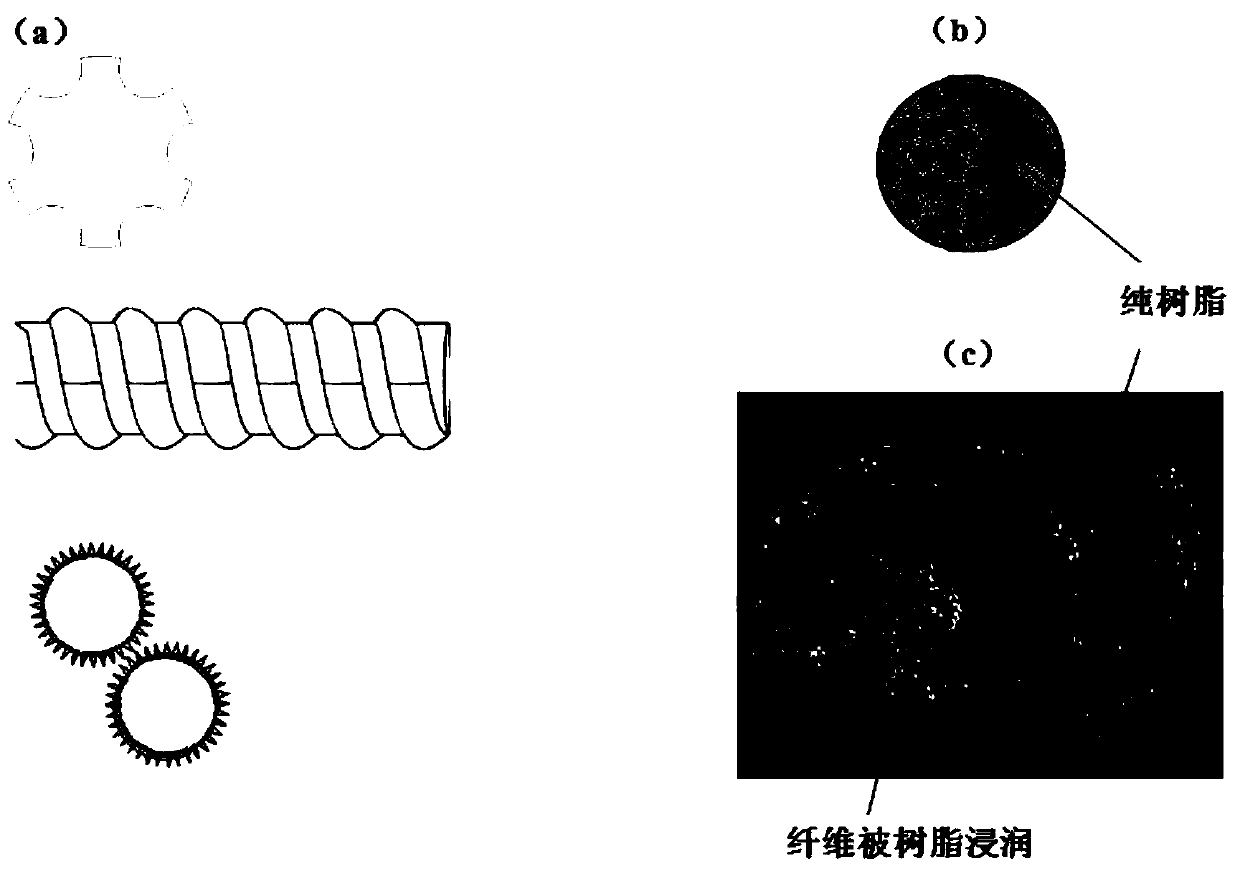

Embodiment 1

[0071] Such as Figure 6 As shown, a long fiber bundle melt impregnation system constructed according to the teachings of the present invention includes a drive unit 31 and an impregnation chamber 32 for providing the rotational power of the drive sleeve roller. The drive unit includes a gear box, a motor, a frequency conversion gears, worm gears, chains, connecting rods and other mechanism components, the impregnation chamber 32 is provided with three sets of matching pairs of drive rollers 33, and the drive rollers 33 are axially provided with arc grooves, the projection of which is The surface graph is a sinusoidal curve with an amplitude of 1 mm and a period of 6. The first driving roller of the matching paired driving sleeve rollers rotates counterclockwise when working, and the second driving roller rotates clockwise. Three sets of matching pairs The rotation mode of the drive sleeve is the same. The side walls of the impregnation chamber 32 are respectively provided wi...

Embodiment 2

[0077] A long fiber bundle melt impregnation system provided by the present invention includes a drive unit and an impregnation chamber for providing rotational power for driving sleeve rollers, and the drive unit includes a gear box, a motor, a frequency converter, a gear, a worm gear, and a chain , connecting rods and other mechanism components, the impregnation chamber is provided with 4 sets of matched pairs of driving sleeve rollers, and the driving sleeve rollers are provided with arc grooves in the axial direction, and the projection surface pattern is 0.5mm in amplitude and 4 Sinusoidal curve, the first driving roller of the matching paired driving sleeve rollers rotates counterclockwise during work, the second driving roller rotates clockwise, and the rotation mode of the 4 sets of matching paired driving sleeve rollers is opposite. The side walls of the impregnation chamber are respectively provided with a long fiber inlet channel, a melt inlet die and an outlet die. ...

Embodiment 3

[0083] A long fiber bundle melt impregnation system provided by the present invention includes a drive unit and an impregnation chamber for providing rotational power for driving sleeve rollers, and the drive unit includes a gear box, a motor, a frequency converter, a gear, a worm gear, and a chain , connecting rods and other institutional components, the impregnation chamber is provided with 5 sets of matched pairs of driving sleeve rollers, and the driving sleeve rollers are provided with arc grooves in the axial direction. curve, the first driving roller of the matching paired driving rollers rotates counterclockwise during work, the second driving roller rotates clockwise, and the rotation mode of the 5 groups of matching paired driving rollers is opposite. The side walls of the impregnation chamber are respectively provided with a long fiber inlet channel, a melt inlet die and an outlet die.

[0084] To produce 50% long glass fiber reinforced TPU (thermoplastic polyuretha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com