Three-section honing material-pressing sleeve for automotive piston ring

An automobile piston, three-stage technology, applied in the field of piston ring production equipment and tooling, can solve the problems of inconvenient production, bulkiness of operators, affecting production efficiency and economic benefits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

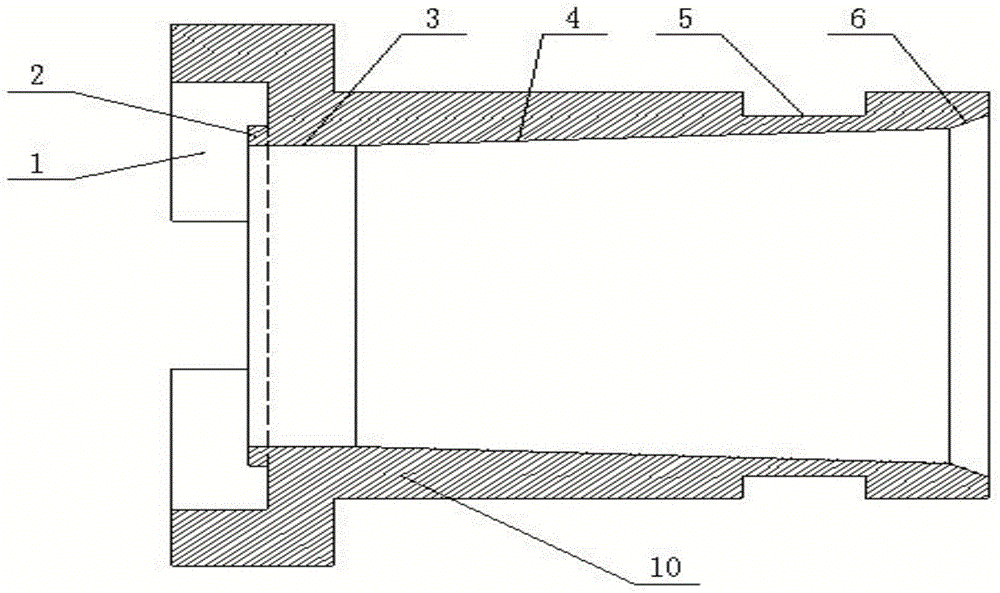

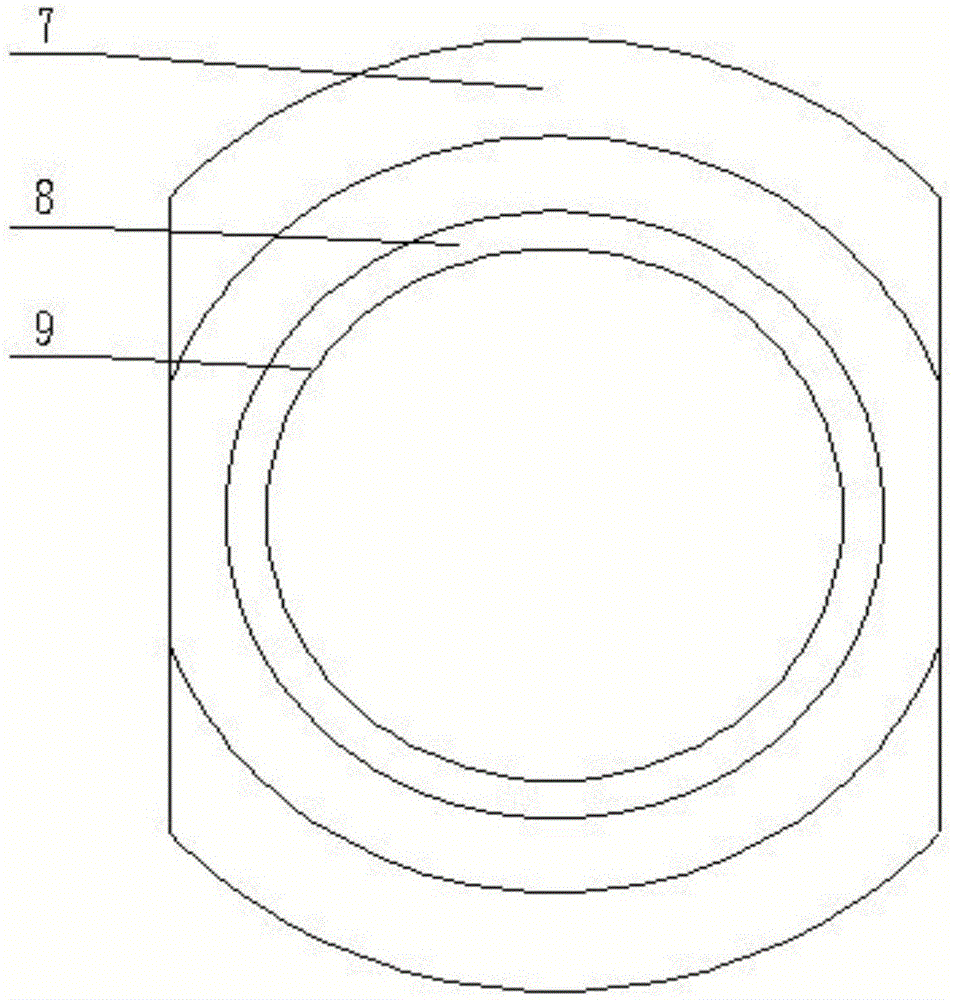

[0008] A kind of automobile piston ring three-stage type honing binder sleeve that this uses is described in further detail below in conjunction with accompanying drawing.

[0009] Depend on figure 1 , figure 2 It can be seen that this implementation is a three-stage honing binder sleeve for automobile piston rings, which mainly consists of: positioning retaining rings (1, 7), transition bosses (2, 9), first bell mouth (6), second Section bell mouth (4), the third stage pressure inlet (3), process cutting groove (5), binder sleeve body (3), binder sleeve body (10) constitutes.

[0010] In this technical solution, the main technical solution of the three-stage honing binder sleeve for automobile piston rings is to make the inner diameter of the binder sleeve into three sections, and the bell mouth (6) of the first section can be manually honed. It is easy to install, and then the installed piston ring can be pressed into the second bell mouth (4) by manpower with the help of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com