Welding gun

A welding gun and connecting sleeve technology, which is applied in the field of welding guns, can solve the problem that the comprehensive performance of welding parts is not very good, and achieve the effects of avoiding heat loss, reliable sealing method and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

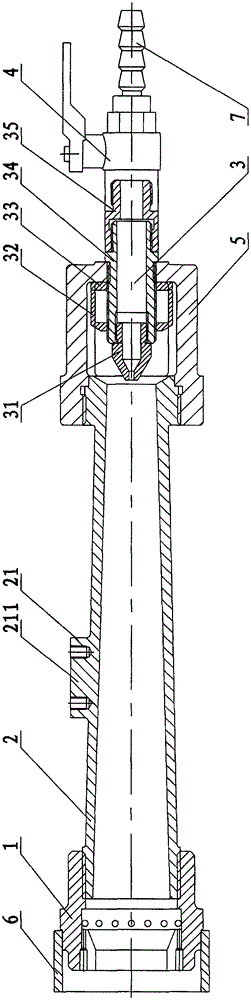

[0020] As an embodiment of the welding gun of the present invention, such as figure 1 As shown, it includes a spray head 1, an air chamber 2, a nozzle assembly 3 and a ball valve 4. The spray head 1 and the air chamber 2 are connected through pipe threads, and the air chamber 2 and the nozzle assembly 3 are connected through a connecting sleeve 5. The nozzle The assembly 3 is connected with the ball valve 4 through a pipe thread, and the spray head 1 is arc-shaped. The nozzle 1 is used as a flame outlet, the gas cavity 2 is used as a channel for natural gas, the nozzle assembly 3 is used to mix air and natural gas, and is input into the gas cavity 2, and the ball valve 4 is used to control the switch of natural gas; The connection method of pipe thread is adopted, and Teflon tape is required to be added during assembly, and then tightened. This kind of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com