A single point integrated mold

An integrated mold and single-point technology, applied in the field of mechanical engineering, can solve problems such as low efficiency, long production cycle, and high cost, and achieve the effects of saving costs, enhancing strength, and avoiding processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

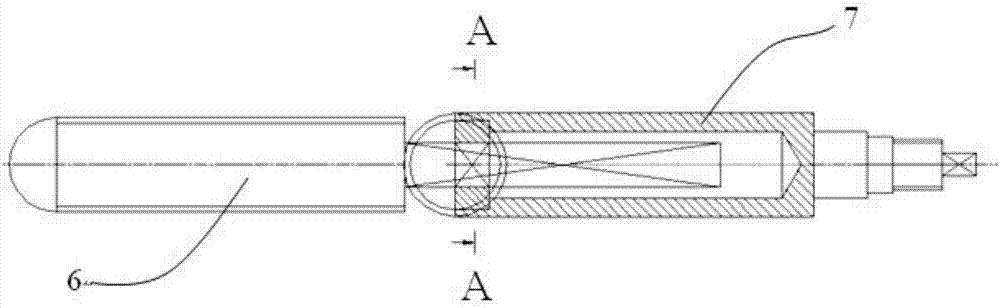

[0027] refer to figure 1 As shown, it consists of a plurality of single-point support mechanisms 1, an upper support plate 2, a lower support plate 3, a vertical plate 4 and a driving motor 5;

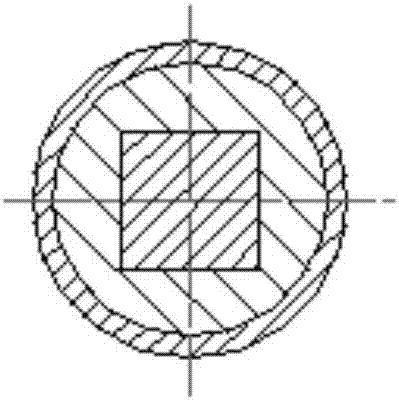

[0028] The single-point support mechanism 1 is composed of a spiral up and down movable ejector rod 6 and a fixed rotary drive handle 7, and the single-point support mechanism 1 is arranged in a square matrix and a circular matrix at a certain distance to form a mold; the upper A hole 8 with an internal thread is processed on the support plate, and a light hole 9 is provided on the lower support plate;

[0029] The upper part of the screw 6 that can move up and down is a cylinder with threads, and the lower part is a geometric body with at least one surface as a plane;

[0030] The threaded cylinder on the upper part of the spiral up and down movable ejector rod 6 and the internally threaded hole 8 on the upper support plate form a spiral ascending or descending motion pair;

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com