Nonwoven fabric liquid distribution system

A technology of liquid dispensing system and non-woven fabric, which is applied in the direction of mixer accessories, dissolving, mixing machines, etc., can solve the problems of controllability difference, low liquid dosing efficiency, weighing and dosing accuracy, etc., and achieve uniform concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions claimed in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

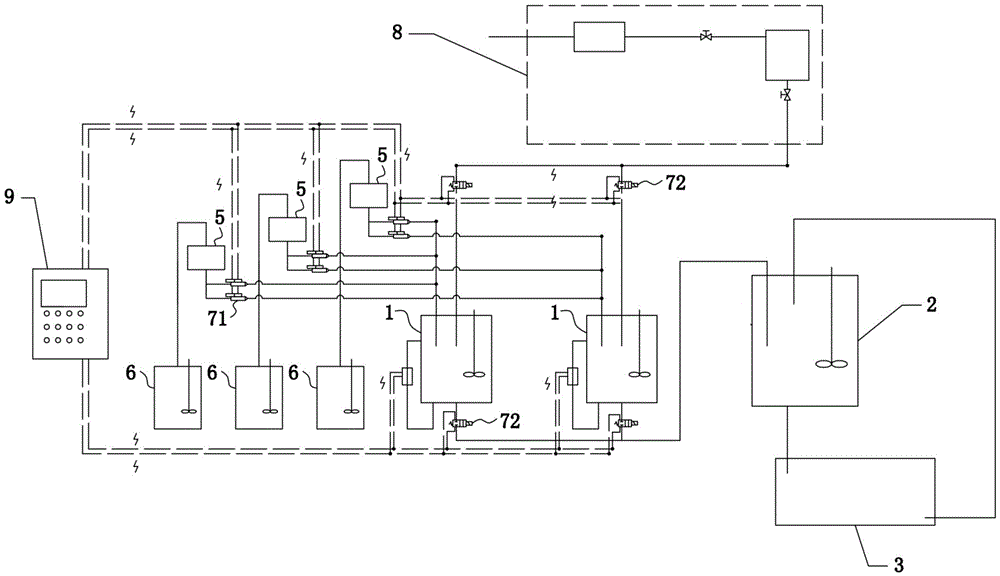

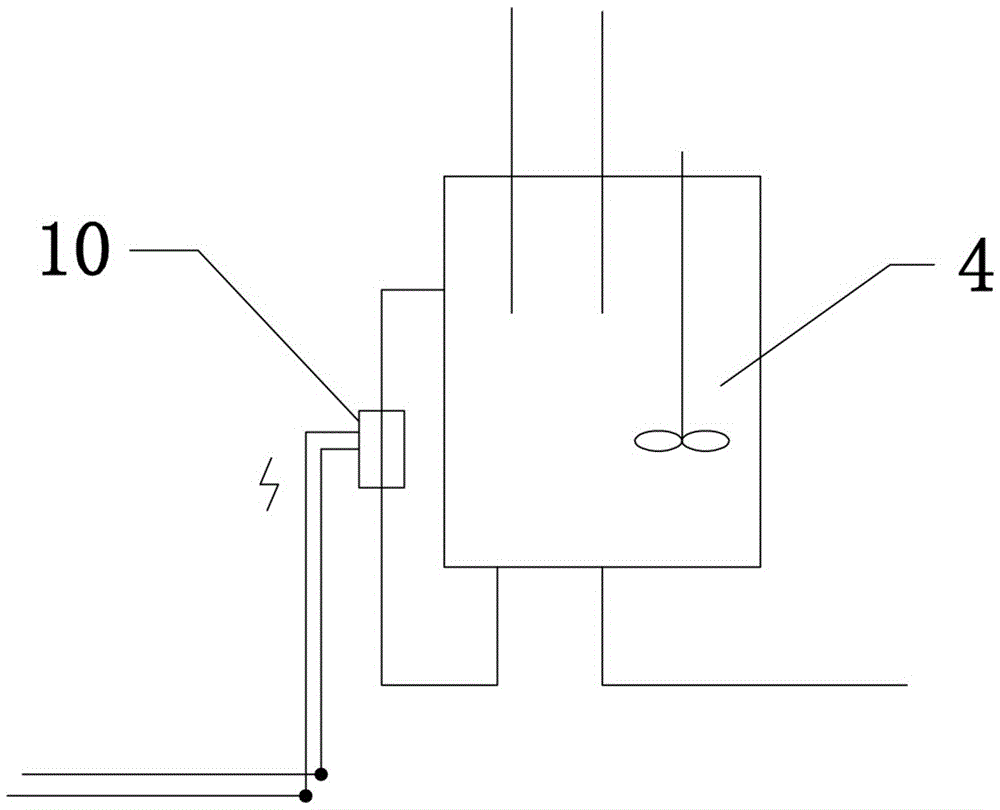

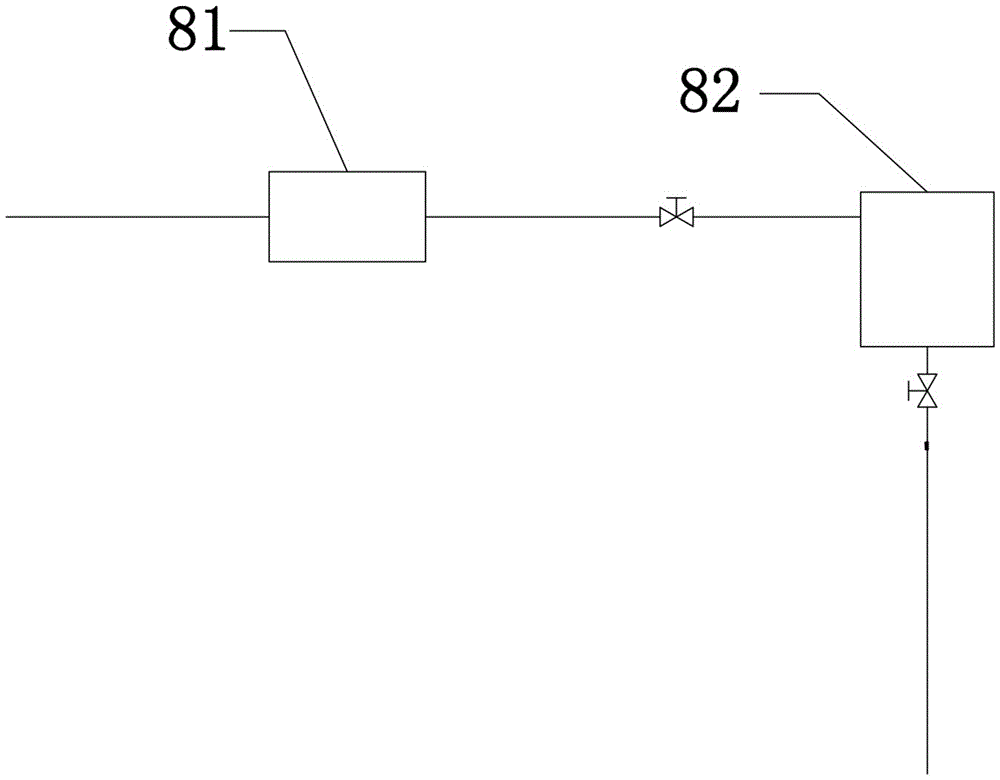

[0016] See attached figure 1 to attach image 3 As shown, a non-woven liquid distribution system in this embodiment includes a plurality of independent liquid distribution tanks 1, a liquid storage tank 2, N high-level tanks 5, N oil agent tanks 6 and liquid loading devices 3. Both the liquid distribution tank 1 and the liquid storage tank 2 are equipped with an agitator 4 whose rotation axis deviates from the axis of the tank body, and the water inlet of each liquid distribution tank 1 is also connected to the soft water supply system through an infusion pipeline with a solenoid valve 72 8. Each oil agent tank 6 is equipped with an agitator 4 whose rotating shaft deviates from the axis of the tank body. The agitator 4 can avoid the precipitation and separation of the oil agent and keep the concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com