Tea leaf processing method and tea leaves

A processing method and tea technology, applied in the field of tea processing, can solve problems such as insufficient degradation of macromolecules, affect product quality, and be unfavorable to ice crystals, so as to improve utilization rate and effective quality, make tea quality more stable, and be easy to learn and master Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

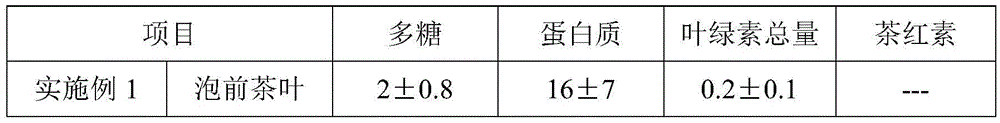

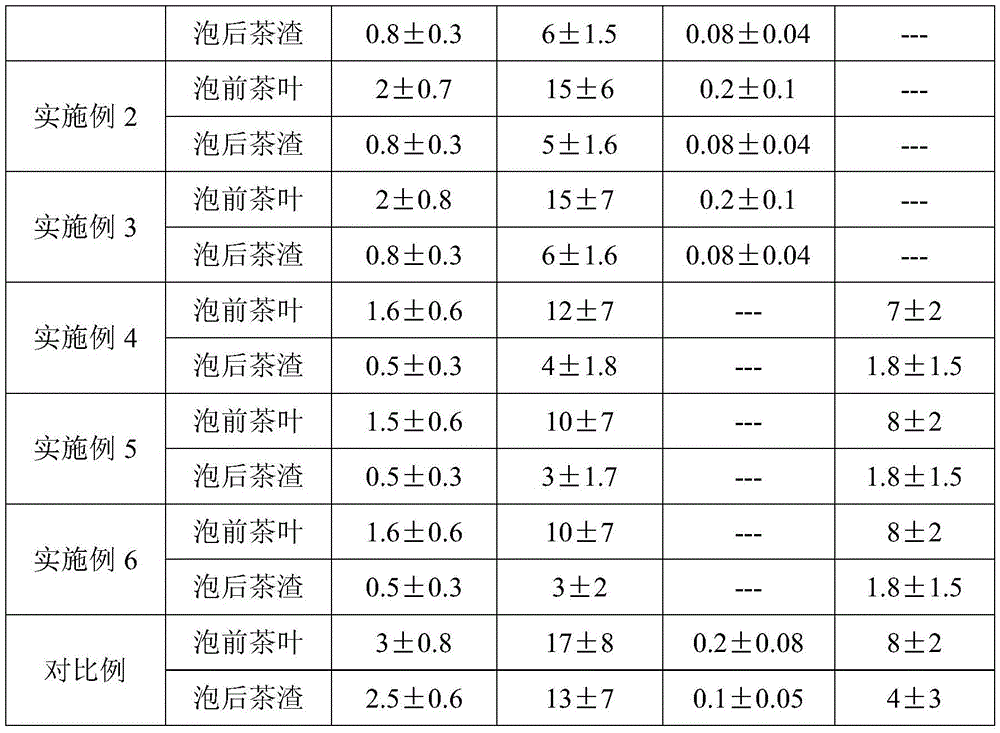

Examples

Embodiment 1

[0040] The tea processing method of the present embodiment comprises the following steps:

[0041] 1) After picking, the tea leaves do not need to be cooled, directly put in a basket without pressing, and freeze at a low temperature of -20 °C for 5 hours in a fluffy state, until completely frozen, and the cells are swelled and burst by the increase of the volume of water frozen. frozen tea leaves;

[0042] 2) the frozen tea leaves obtained in step 1) are withered for 80 min under room temperature (10° C.) conditions, during which the tea leaves are turned to make the water loss uniform, the water loss of the tea leaves is controlled within 25% during the withering period, and the water loss is until the leaves are slightly softened. ;

[0043] The withered tea leaves are cured by microwave at 200°C for 30s (controlling the water loss of the tea leaves to not exceed 50% of the total water content), rolled and shaped, and dried at 60°C until the water content of the tea leaves ...

Embodiment 2

[0045] The tea processing method of the present embodiment comprises the following steps:

[0046] 1) After picking, the tea leaves do not need to be cooled, directly put in a basket without pressing, and freeze at a low temperature of -40°C for 3 hours in a fluffy state until completely frozen, and the cells are swelled and burst by the increase in the volume of water freezing. frozen tea leaves;

[0047] 2) the frozen tea leaves obtained in step 1) are placed under room temperature (20° C.) conditions for 60min withering, during which the tea leaves are turned over to make the water loss uniform, and the water loss of the tea leaves is controlled within 25% during the withering period, and the water loss is until the leaves are slightly softened. ;

[0048] The withered tea leaves are microwaved at 180°C for 1 min (controlling the water loss of the tea leaves to not exceed 50% of the total water content), rolled and shaped, and dried at 70°C until the water content of the t...

Embodiment 3

[0050] The tea processing method of the present embodiment comprises the following steps:

[0051] 1) After the tea leaves are picked, do not need to cool down, put them in the basket directly, do not press, and freeze them in a fluffy state at a low temperature of -30 °C for 4 hours until they are completely frozen. frozen tea leaves;

[0052] 2) the frozen tea leaves obtained in step 1) are placed in room temperature (15° C.) withering for 70min, during which the tea leaves are turned over to make the water loss uniform, the water loss of the tea leaves is controlled within 25% during the withering, and the water loss is to the point where the leaves are slightly softened. ;

[0053] The withered tea leaves are subjected to a 190°C drum for 3 minutes (controlling the water loss of the tea leaves to not exceed 50% of the total water content), rolling and shaping, and drying at 65°C until the water content of the tea leaves is below 8% to obtain green tea. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com