Cereal drying mechanism

A grain drying and drying technology, which is applied in the direction of saving seeds through drying, can solve the problems of increasing crushing, affecting quality, affecting ventilation and drying, etc., and achieves the effects of avoiding blockage, enhancing versatility, and good ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, which should not be construed as a limitation of the present invention;

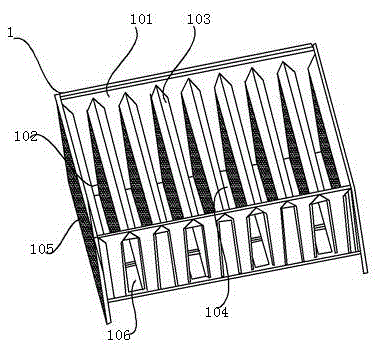

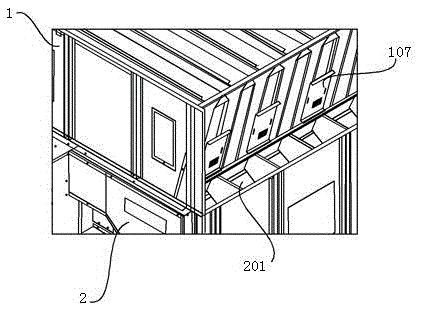

[0017] as attached Figure 1-3 As shown, a grain drying mechanism includes a drying part 1 and a lower drying body 2, and the drying part 1 and the lower drying body 2 are connected as a whole, wherein:

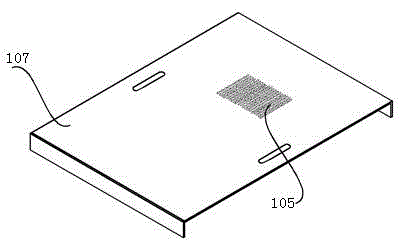

[0018] The drying section 1 is composed of a side plate 101 and a mesh plate 102, the side plate 101 and the mesh plate 102 surround to form a space structure, and the mesh plates 102 are spliced to form a closed tower structure 103, And along the side plate 101 evenly inserted in the inside of the drying part 1, the drying part 1 is divided into at least five semi-closed grooves 104, and the through holes 105 are evenly distributed on the mesh plate 102, and the through holes 105 are set as Oval or waist-shaped structure, the diameter of the through hole 105 is ∮1.5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com