Automatic stamping and laminating equipment of PI reinforcement plates for FPC

A reinforcing board and automatic technology, applied in the direction of bendable/stretchable parts of the circuit, electrical components, printed circuit parts, etc., can solve the problems of reduced production efficiency, reduced work efficiency, and time-consuming, etc., to achieve Improve work efficiency, save labor costs, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

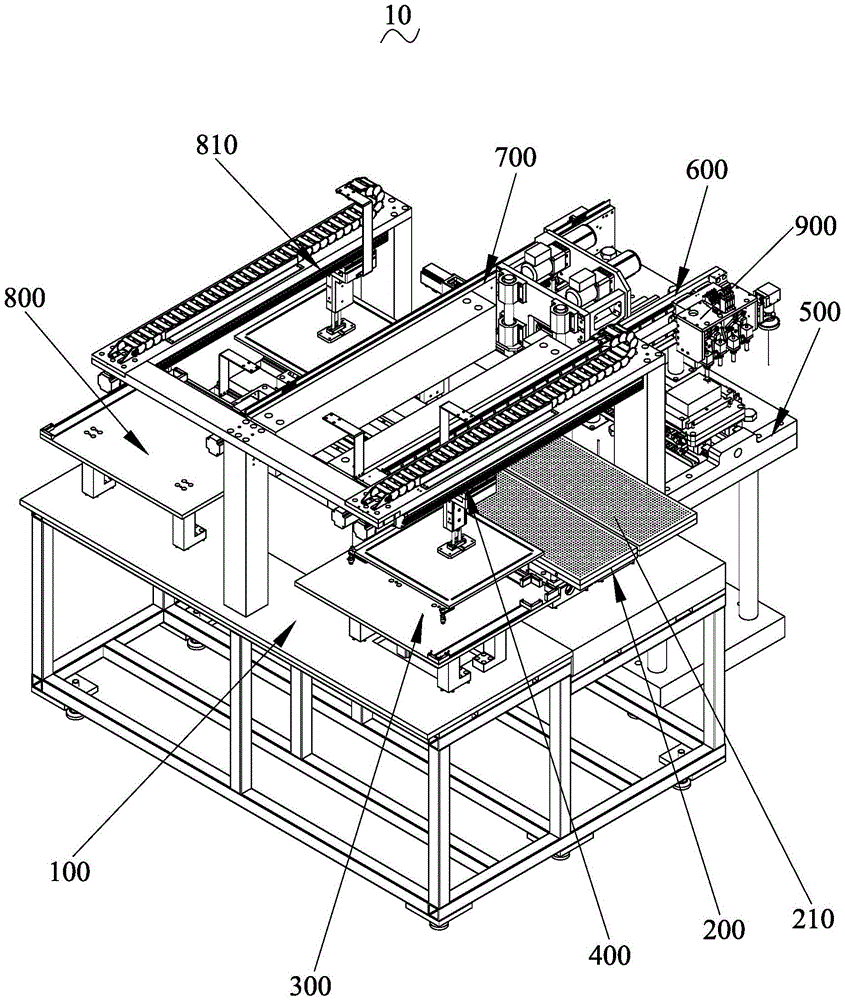

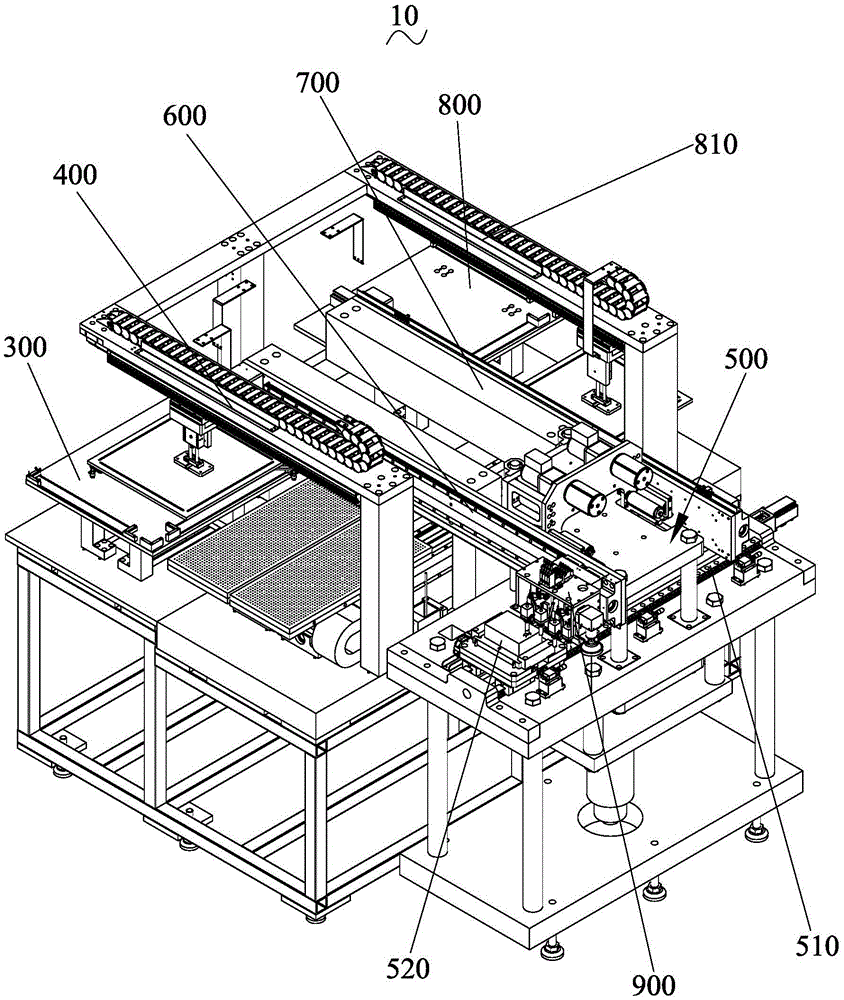

[0027] Such as figure 1 Shown is a structural diagram of an automatic punching and pasting device 10 for PI reinforcing plates for FPC according to an embodiment of the present invention, figure 2 for figure 1 It is a schematic diagram of another viewing direction of the automatic punching and affixing equipment 10 for PI reinforcement boards for FPC shown.

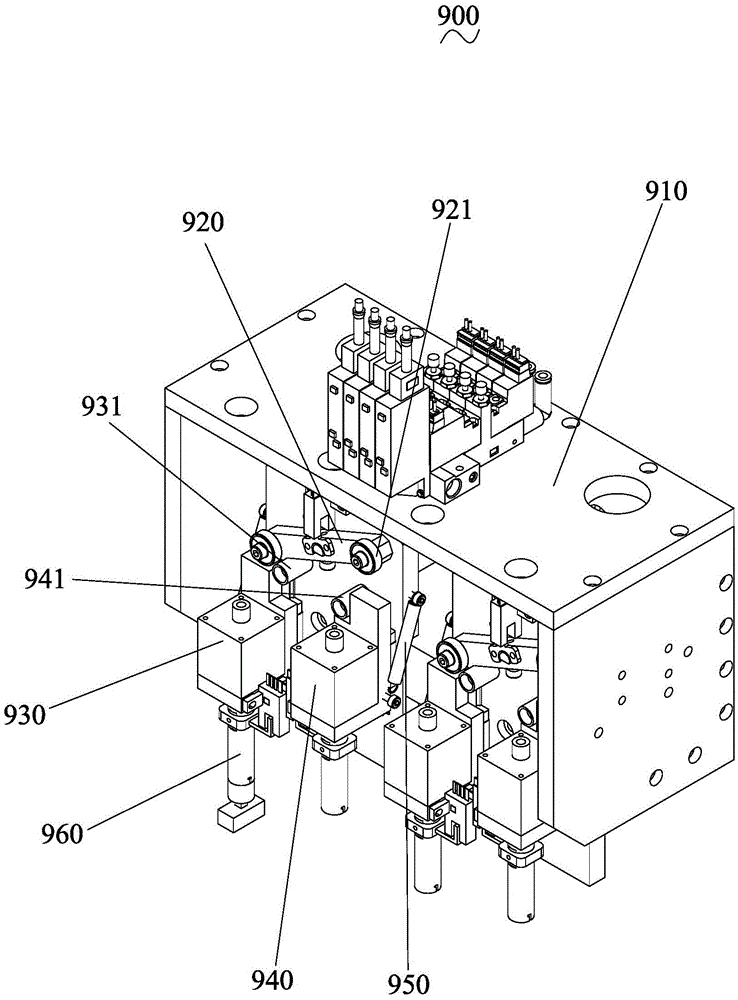

[0028] The PI reinforcement plate automatic punching and pasting equipment 10 for FPC includes: workbench 100, intermediate transfer station 200, FPC storage tray 300, FPC feeding manipulator 400, PI reinforcement plate punching device 500, first PI supplementary plate Strong plate laminating manipulator 600, second PI reinforcing plate laminating manipulator 700, finished product receiving tray 800 and finished ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com