A method for on-site assembly of UHV converter transformers

A converter transformer and on-site assembly technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of large capacity, high voltage level of 10,000MW UHV DC projects, and reduce the difficulty of selection and design and the effect of manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0039] The basic principles of on-site assembly of a UHV converter transformer on-site assembly method provided by the present invention include: (1) minimizing the number of disassembled parts; (2) maintaining the integrity of the transformer to the greatest extent; (3) shortening the The exposure time in the air; (4) reduce the on-site installation process and workload; (5) take into account the reduction of the difficulty of the on-site test.

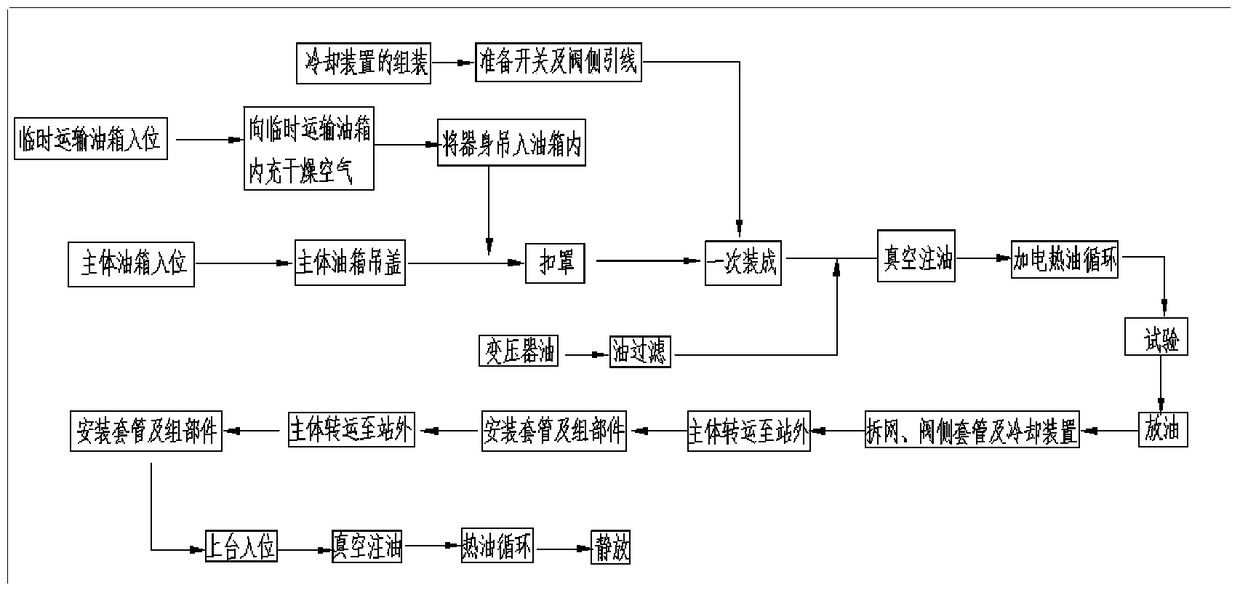

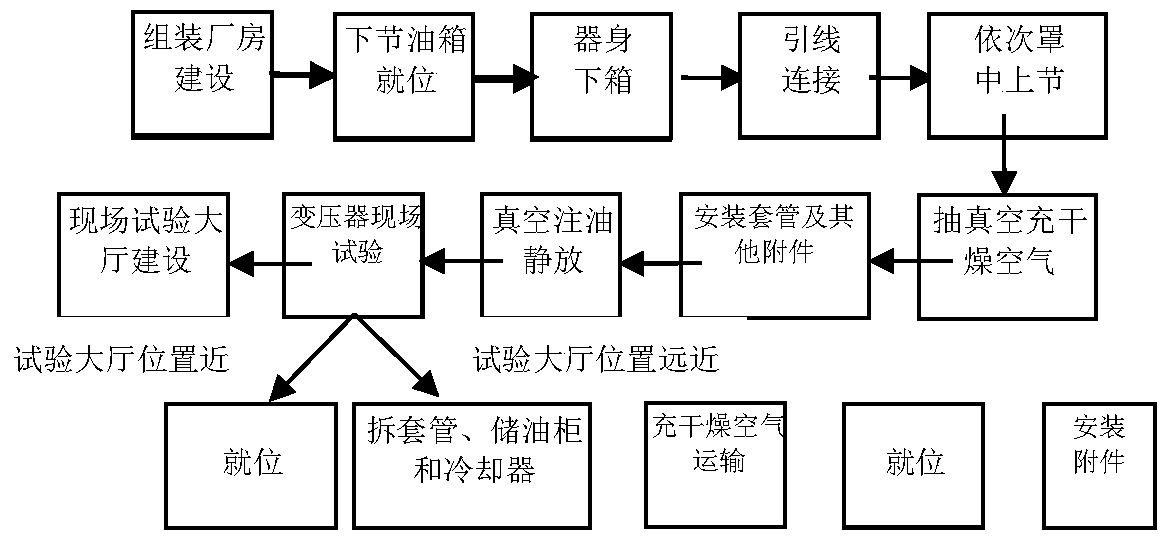

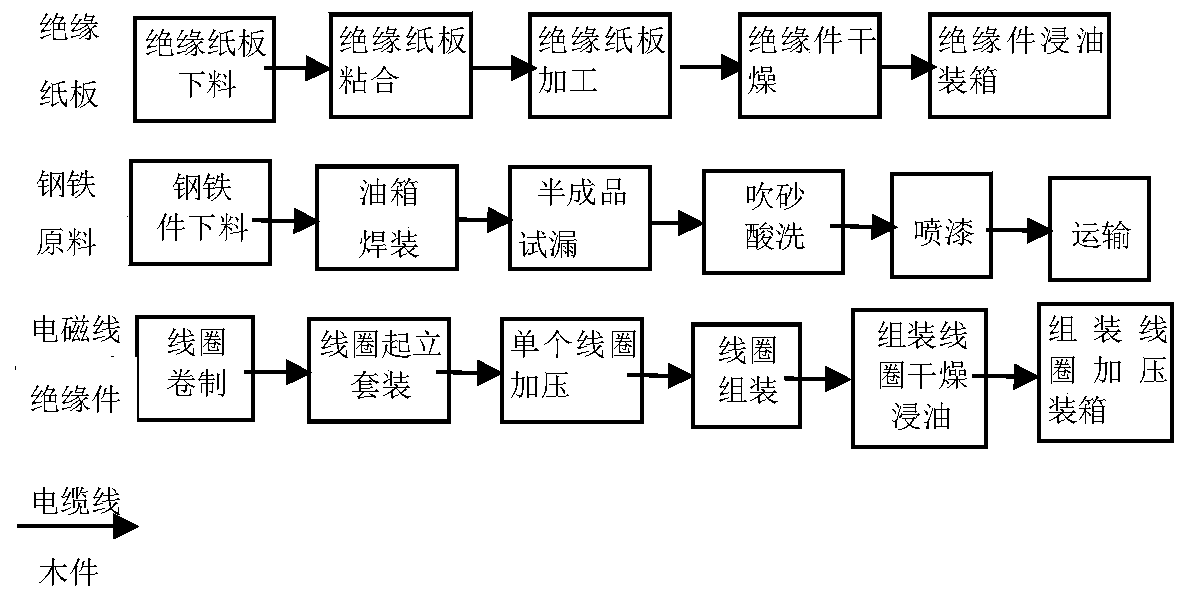

[0040] The present invention provides four schemes for the on-site assembly method of the UHV converter transformer. The first option is that the UHV converter body is transported in a temporary oil tank with a small size. Option two is that the two bodies are in the same fuel tank. The third option is that core stacking, body assembly and almost all key production steps and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com