Engine locking double-motor single-planetary-line two-stage speed reduction hybrid power system

A hybrid power system, two-stage deceleration technology, applied in the field of power system, can solve the problems of increasing system energy consumption, coil aging, reducing system efficiency, etc., to reduce the difficulty of design and manufacturing, reduce system energy consumption, and improve system efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

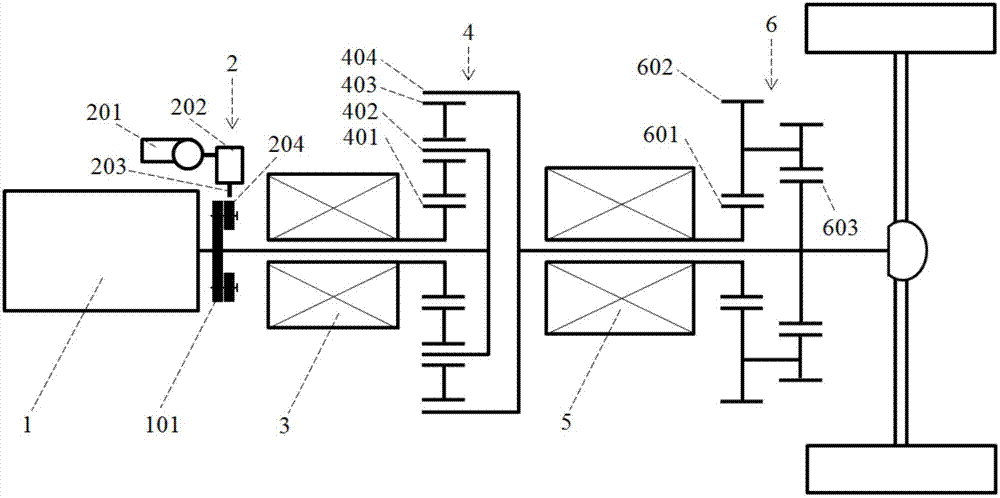

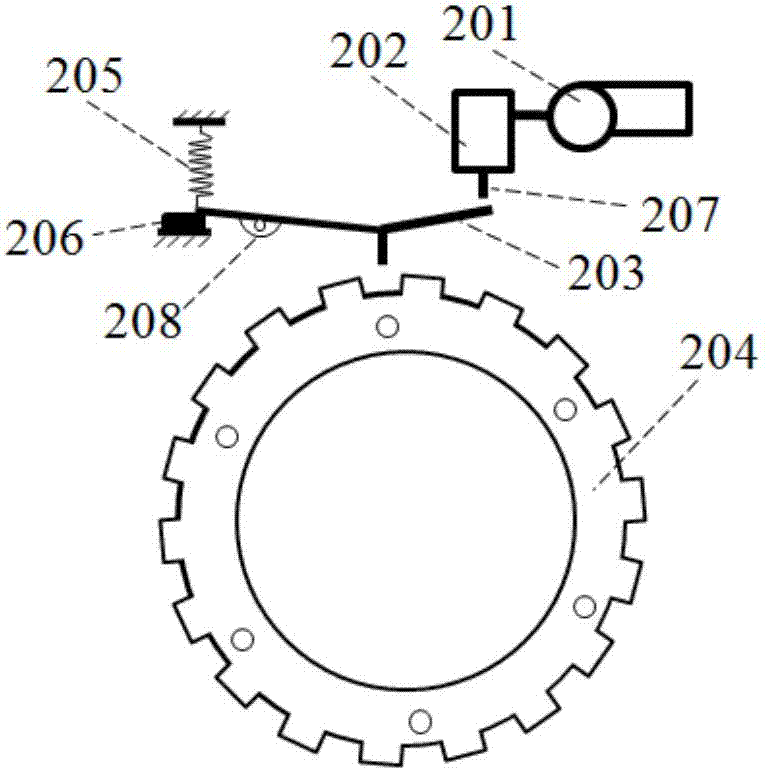

[0024] An engine-locking dual-motor single planetary row two-stage deceleration hybrid power system, such as figure 1 As shown, it includes an engine 1, an engine locking mechanism 2, a first motor 3, a planetary gear mechanism 4, a second motor 5, and a two-stage reduction mechanism 6; the engine locking mechanism 2 is driven by a worm gear reduction motor 201; The planetary gear mechanism 4 includes a sun gear 401, a planet carrier 402, a planetary gear 403, and a ring gear 404; the two-stage reduction mechanism 6 includes a driving gear 601, an intermediate shaft gear 602, and a driven gear 603; the engine 1 The flywheel 101 is connected with the engine locking mechanism 2; the engine 1 is connected with the planet carrier 402; the first motor 3 is connected with the sun gear 401; the second motor 5 is connected with the driving gear 601; the ring gear 404 is connected with the driven gear 603; the driving gear 601 is meshed with the countershaft gear 602; the countershaft ...

Embodiment 2

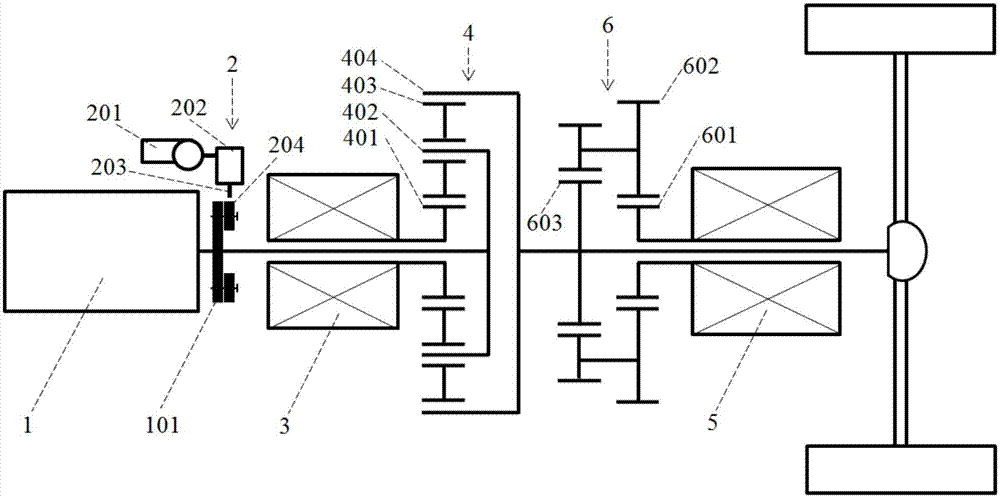

[0032] An engine-locking dual-motor single planetary row two-stage deceleration hybrid power system, such as figure 2 As shown, the difference from Embodiment 1 is that in Embodiment 1, the second motor 5 is arranged between the planetary gear 4 and the two-stage reduction mechanism 6, and in Embodiment 2, the second motor 5 is arranged between two stages Speed reduction mechanism 6 outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com