Real-time dynamic measurement method for measuring radial clearance between steam turbine rotor and stator

A technology of real-time dynamic measurement and steam turbine rotor, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of difficult and accurate real-time dynamic measurement of radial clearance, so as to save downtime and overhaul time, fast response, and ensure safe and economical operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples of implementation.

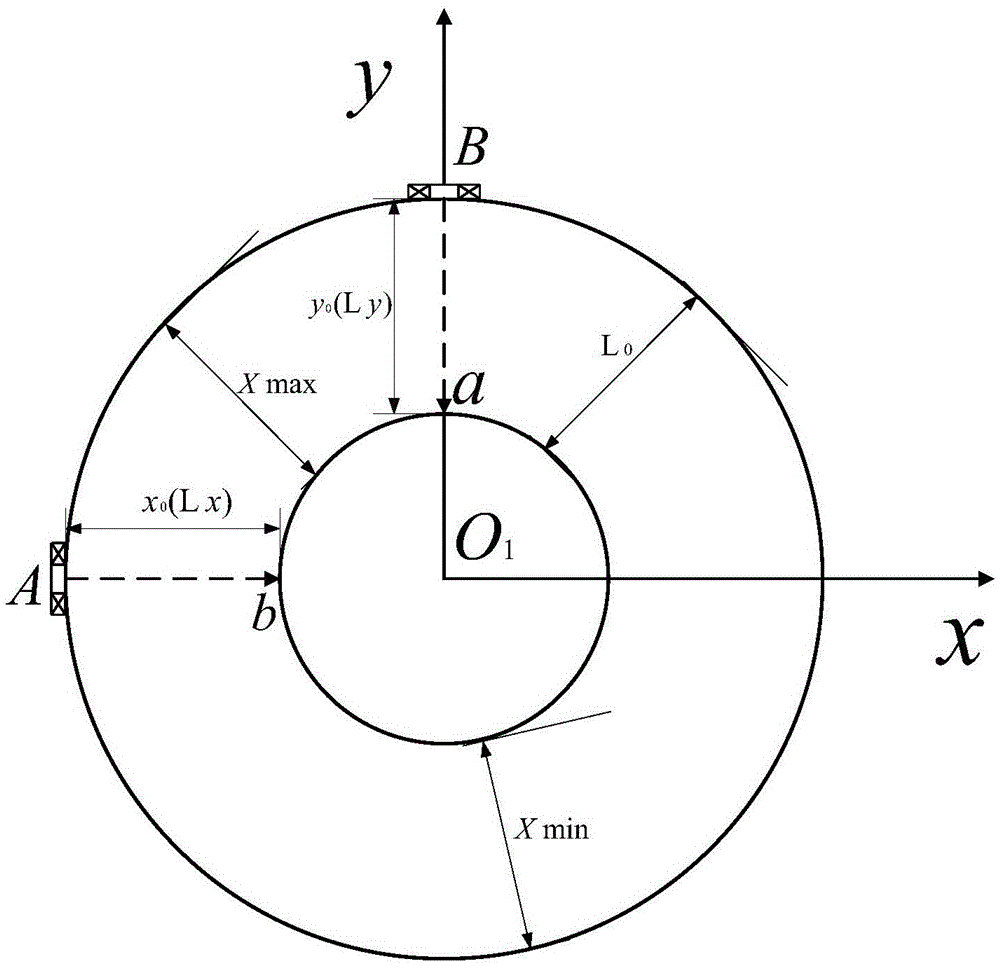

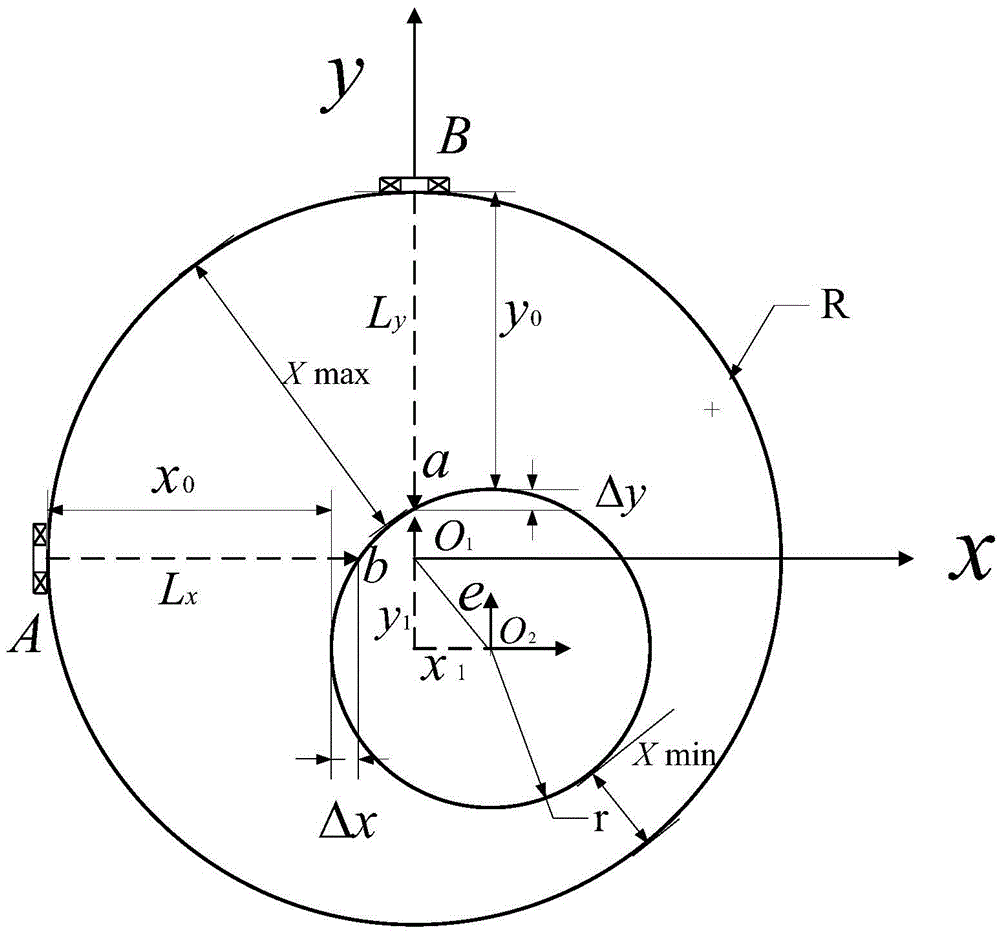

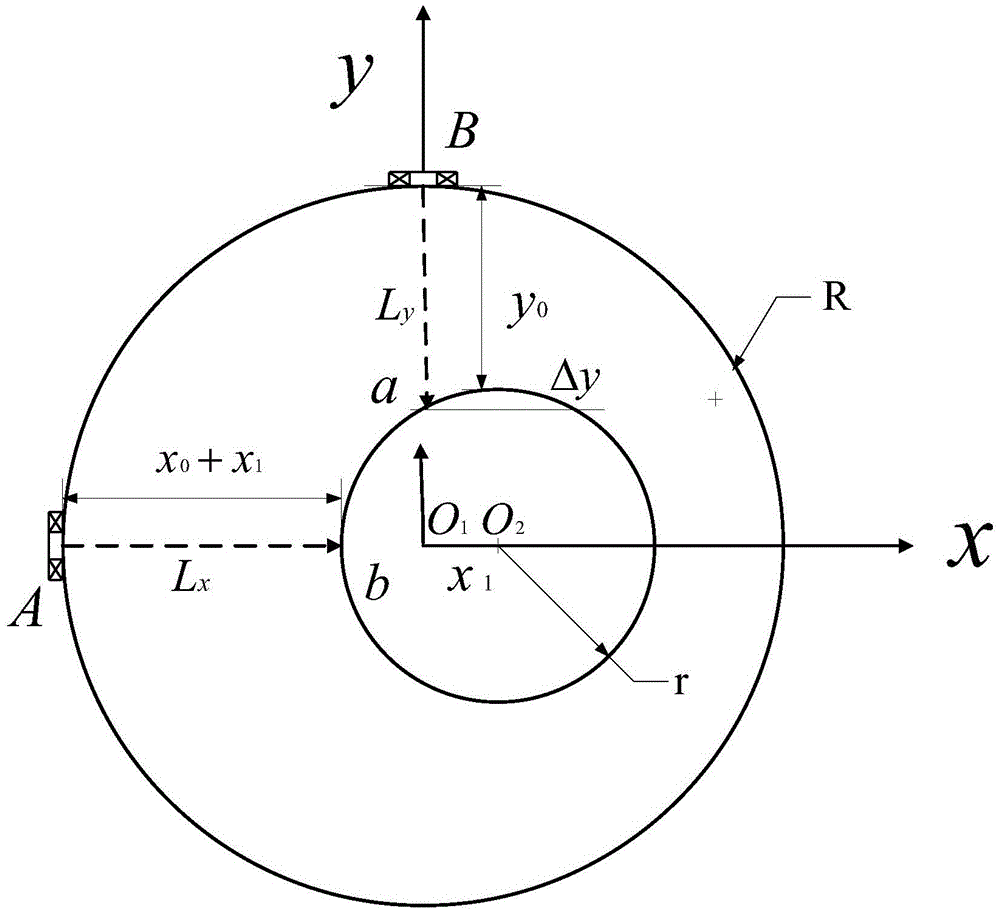

[0028] refer to Figure 1 ~ Figure 4 , a kind of real-time dynamic measuring method of the radial gap between the steam turbine rotor and the stator provided by the present invention, comprising the following contents:

[0029] a. Selection of distance measuring device

[0030] Two high-frequency phase laser range finders are selected to measure the radial clearance of the steam turbine flow part. The high-frequency phase laser rangefinder uses the phase difference of the modulated light emitted by the transmitter to reflect the reflected light back to the receiver through the cooperative target to achieve distance measurement. A decentralized direct measuring ruler combination method that can meet both the accuracy and the measurement distance is adopted to measure the gap respectively by combining two lasers with different fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com