Inner fin and outer rib reinforced corrugated pipe

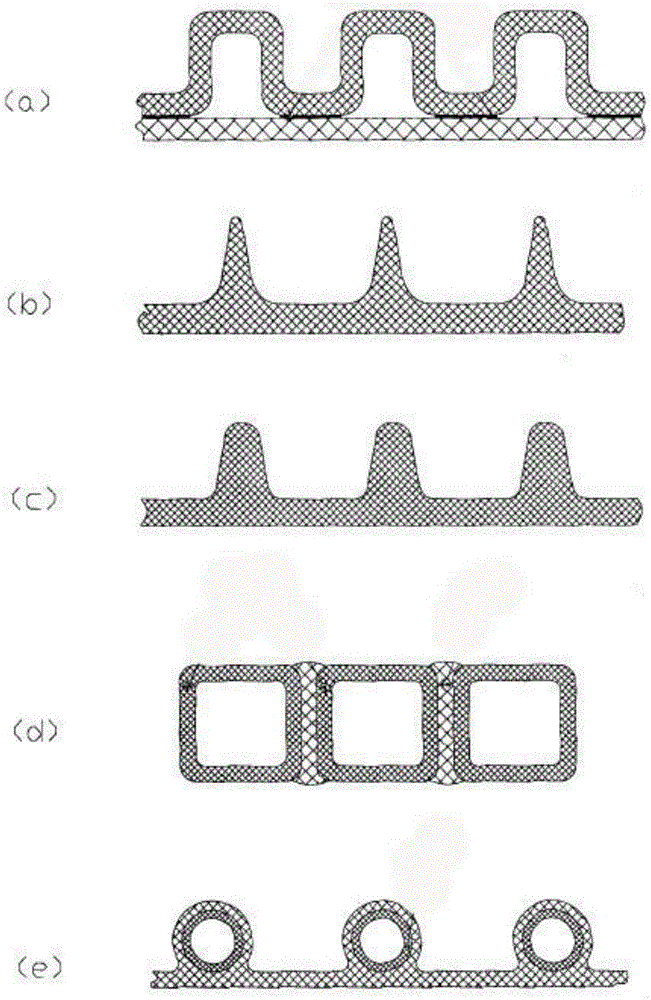

A corrugated pipe and inner rib technology, which is applied to the field of corrugated pipes reinforced with inner ribs and outer ribs, can solve the problems of complex use environment of large-diameter pure plastic pipes, performance limitations of corrugated pipes such as compression resistance, deformation resistance and pipe-soil effect, etc. Strong anti-deformation ability and good ring stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

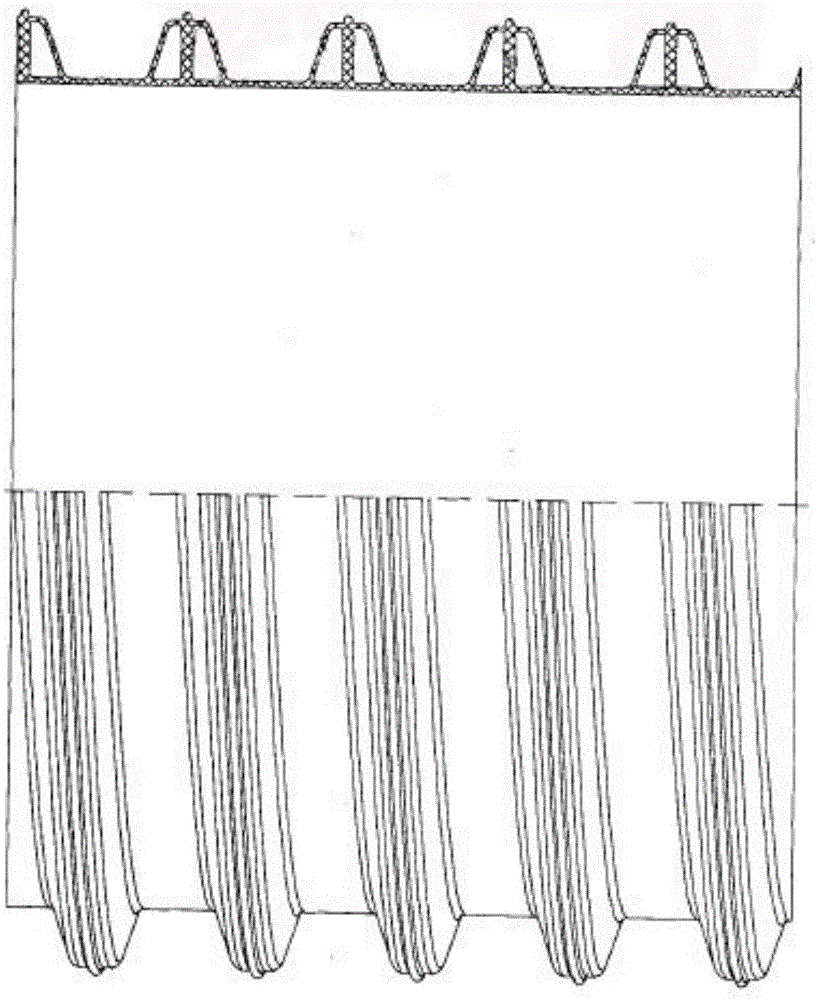

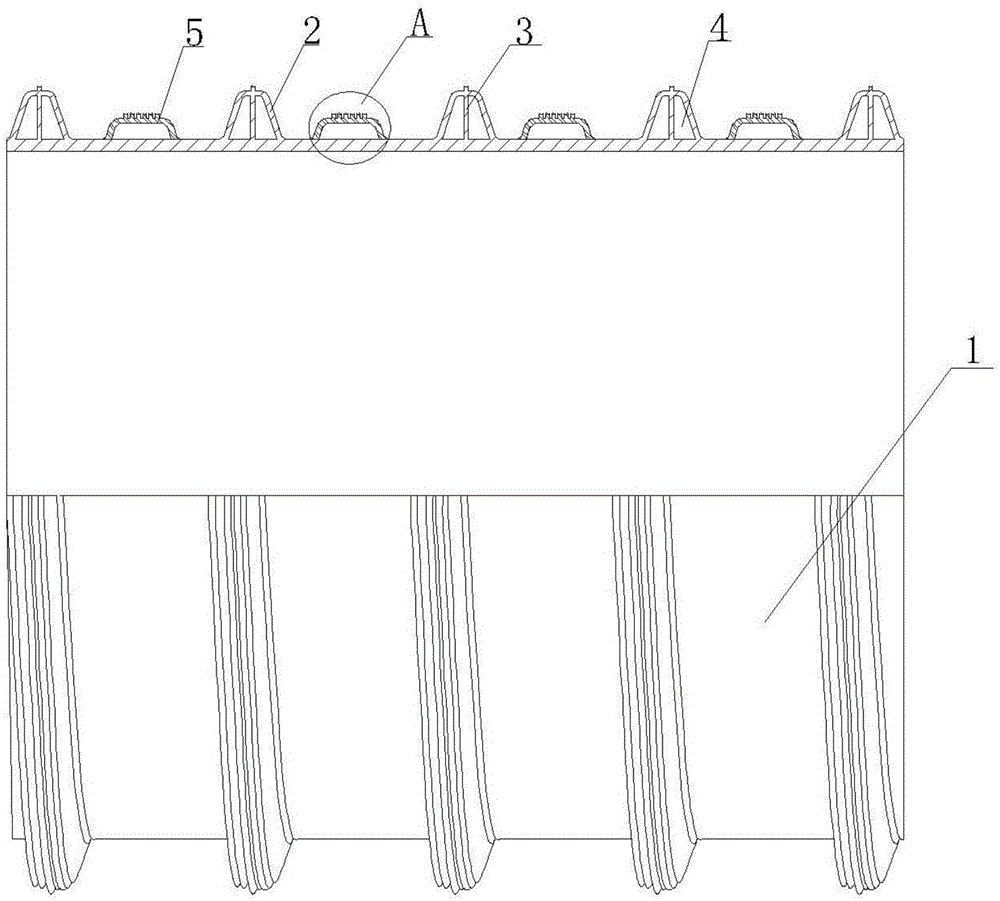

[0040] Such as image 3 and 4 As shown, a corrugated pipe reinforced with internal ribs and external ribs includes a cylindrical pipe body 1 and a spiral surround 2 that spirally surrounds the outside of the pipe body. The spiral surround 2 contains a reinforced internal rib 3 perpendicular to the pipe wall. The internal rib 3 Divide the helical circle into two parallel hollow cavities 4, and there is also a transverse reinforcing rib 5 between each adjacent helical surrounding 2, and the transverse reinforcing rib 5 is installed on the cylindrical pipe body 1; the transverse reinforcing Rib 5 installed on the cylindrical pipe body 1 means that the two ends of the transverse reinforcing rib 5 are installed on the surface of the cylindrical pipe body 1, and the space between the transverse reinforcing rib 5 and the cylindrical pipe body 1 is a hollow structure; the transverse reinforcing rib 5 is Made of nano polyethylene material; the outer surface of the transverse reinforce...

Embodiment 2

[0043] Such as Figure 5 and 6 As shown, a corrugated pipe reinforced with internal ribs and external ribs includes a cylindrical pipe body 1 and a spiral surround 2 that spirally surrounds the outside of the pipe body. The spiral surround 2 contains a reinforced internal rib 3 perpendicular to the pipe wall. The internal rib 3 Divide the helical circle into two parallel hollow cavities 4, and there is also a transverse reinforcing rib 5 between each adjacent helical surrounding 2, and the transverse reinforcing rib 5 is installed on the cylindrical pipe body 1; the transverse reinforcing The rib 5 installed on the cylindrical pipe body 1 means that the two ends of the transverse reinforcing rib 5 are installed on the surface of the cylindrical pipe body 1, and the space between the transverse reinforcing rib 5 and the cylindrical pipe body 1 is a hollow structure; it also includes the second cylindrical pipe The body 6, the diameter of the second cylindrical pipe body 6 is s...

Embodiment 3

[0046] as attached Figures 7 to 10 As shown, a corrugated pipe reinforced with internal ribs and external ribs includes a cylindrical pipe body 1 and a spiral surround 2 that spirally surrounds the outside of the pipe body. The spiral surround 2 contains a reinforced internal rib 3 perpendicular to the pipe wall. The internal rib 3 Divide the helical circle into two parallel hollow cavities 4, and there is also a transverse reinforcing rib 5 between each adjacent helical surrounding 2, and the transverse reinforcing rib 5 is installed on the cylindrical pipe body 1; the transverse reinforcing The rib 5 installed on the cylindrical pipe body 1 means that the two ends of the transverse reinforcing rib 5 are installed on the surface of the cylindrical pipe body 1, and the space between the transverse reinforcing rib 5 and the cylindrical pipe body 1 is a hollow structure; it also includes the second cylindrical pipe The body 6, the diameter of the second cylindrical pipe body 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com